Radiation polymerization, crosslinking and grafting synergistic preparation method of Chinese poplar or Chinese sycamore or Chinese pine wood-plastic composite material

A wood-plastic composite material, Chinese sycamore wood technology, applied in the direction of wood treatment, impregnated wood, wood impregnation, etc., to achieve broad application prospects and solve the lack of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

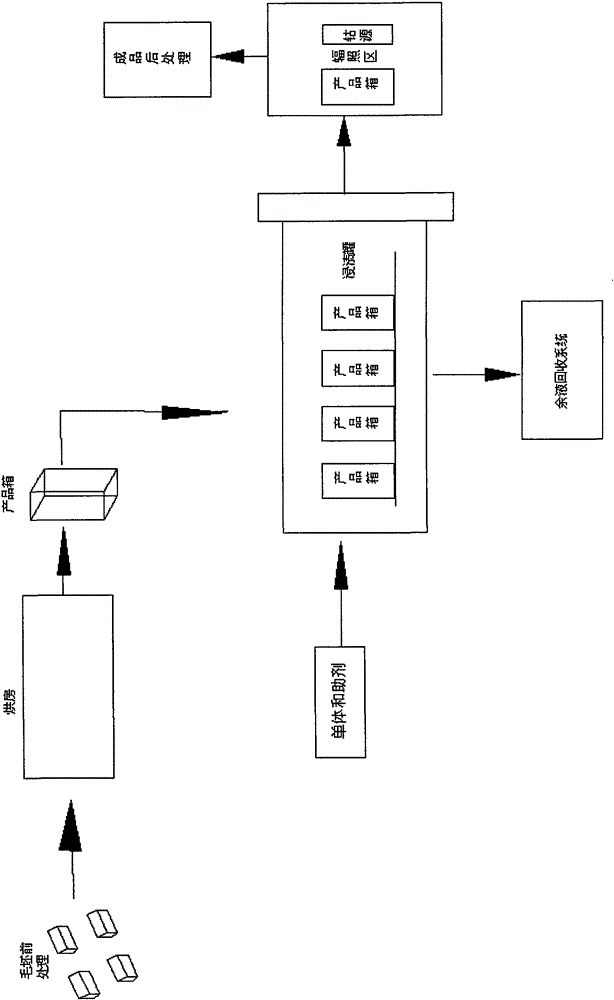

[0022] figure 1 It is a schematic diagram of the process flow of the present invention

[0023] The present invention provides a synergistic preparation method of radiation polymerization, crosslinking and grafting of Chinese poplar or Chinese sycamore or Chinese pine wood-plastic composite material, including pretreatment, monomer impregnation, irradiation and posttreatment procedures, flow process Can refer to accompanying drawing, it is characterized in that:

[0024] 1) Using Chinese poplar wood (Chinese sycamore wood, Chinese pine wood) as the basic material, pre-treat the wood: first make the log into a blank with a suitable size. According to the requirements of the user, the size generally does not exceed 2 meters in length and the thickness does not exceed 2cm, such as 0.3m, 0.6m, 1m, 1.5m, and 2m are optional lengths; 0.3cm, 0.5cm, 0.8cm, 1cm, 1.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com