Preparation method of double-faced compound warm-keeping and energy-saving wallboard

A composite thermal insulation and wallboard technology, applied in chemical instruments and methods, hydraulic material layered products, layered products, etc., can solve problems such as occupation of land resources and environmental pollution, and achieve good hanging performance and fire resistance. Good and good building energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

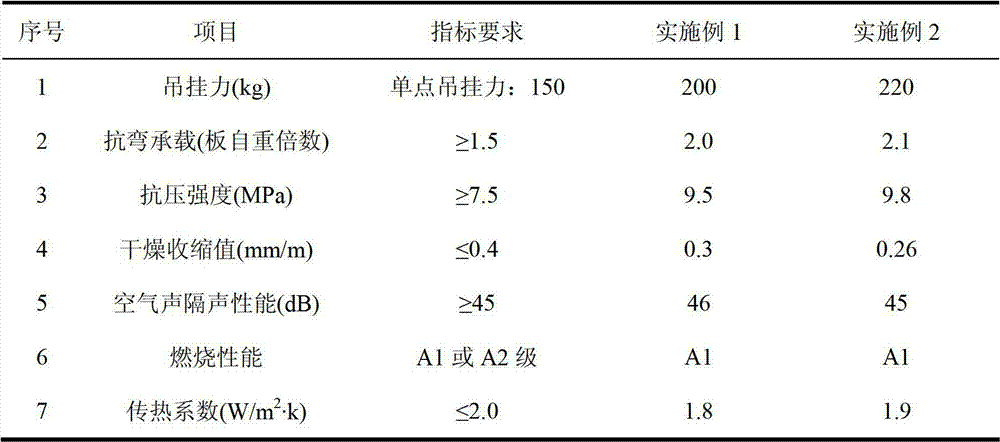

Examples

Embodiment 1

[0019] (1) Prepare the panel: Pour 50% of the bottom ash, 20% of the ground sand and 15% of the lime in the mixer into the mixer and mix evenly, then add 15% of the water and continue to stir until Dry hard slurry, inject the slurry into the prepared panel mold, and then place a certain amount of steel mesh. After three rolls, the bulk density will reach 1900kg / m 3 , and then sent to the autoclave for 8 hours, the temperature and pressure of the water vapor in the autoclave were 200 ° C, 1.6 MPa, and the temperature was naturally cooled for 2 hours after leaving the autoclave. After demoulding, three thicknesses of 6mm, 8mm, and 10mm can be obtained panel.

[0020] (2) Preparation of wall panels: First, fix the two prepared panels on both sides of the wall panel mold according to the design requirements. In addition, by mass percentage, 40% of the bottom ash after incineration of domestic waste for power generation, 10% of lime, 20% of ground sand, 10% of cement, 2% of gypsum...

Embodiment 2

[0022] (1) Preparation of panels: Pour 65% of the bottom ash, 15% of finely ground sand and 5% of lime by mass percentage into the mixer and mix evenly, then add 15% of water and continue to stir until dry For hard slurry, inject the slurry into the prepared panel mold, and then place a certain amount of steel mesh. After three rolls, the bulk density will reach 2200kg / m 3 , and then sent to the autoclave for 8 hours, the temperature and pressure of the water vapor in the autoclave were 184 ° C, 1.2 MPa, and the temperature was naturally cooled for 2 hours after leaving the autoclave. After demoulding, three thicknesses of 6mm, 8mm, and 10mm can be obtained. panel.

[0023] (2) Preparation of wall panels: First, fix the two prepared panels on both sides of the wall panel mold according to the design requirements. In addition, by mass percentage, 30% of the bottom ash after incineration of domestic waste for power generation, 15% of lime, 15% of ground sand, 15% of cement, 4% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com