Patents

Literature

40results about How to "Comply with circular economy requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite mineral additive for high-strength and high-performance concrete and method for preparing concrete

InactiveCN101935179AImprove early strengthReduces dryness and early shrinkage cracksSolid waste managementSlagCircular economy

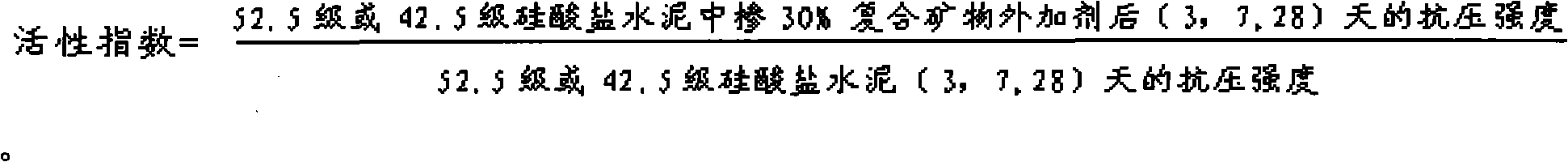

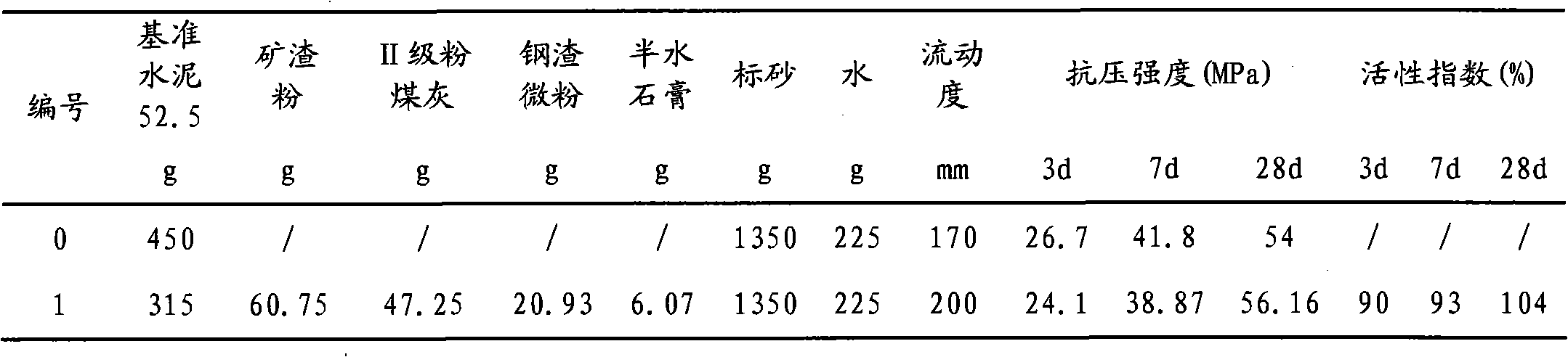

The invention discloses a composite mineral additive for high-strength and high-performance concrete and a method for preparing concrete. The composite mineral additive for the high-strength and high-performance concrete comprises superfine steel slag micro powder as a core material as well as hemihydrate desulfurization gypsum, II-level pulverized fuel ash and mineral slag. The preparation method of the composite mineral additive comprises the following steps of: placing raw materials in a mixer, and then mechanically stirring and uniformly mixing to form the composite mineral additive for the high-strength and high-performance concrete. The composite mineral additive for the high-strength and high-performance concrete, obtained in the method, has high early-stage strength in 3 days, the activity index is not less than 80%, and the activity index in 28 days is not less than S95%, which is higher than the standard of the issued state and local like products; and when used for preparing the concrete, the composite mineral additive can equivalently replace more than 60% of 52.5-level ordinary Portland cement, and meanwhile fragments generated by producing above 75% of broken stones can also be utilized for replacing natural sand, thereby low-carbon concrete having good durability and meeting the circulated economic requirement is produced.

Owner:SHANGHAI UNIV +2

Animal shell substance treating method and device

InactiveCN1814772ANo wasteReduce wasteBioreactor/fermenter combinationsBiological substance pretreatmentsAnimal ShellsWastewater

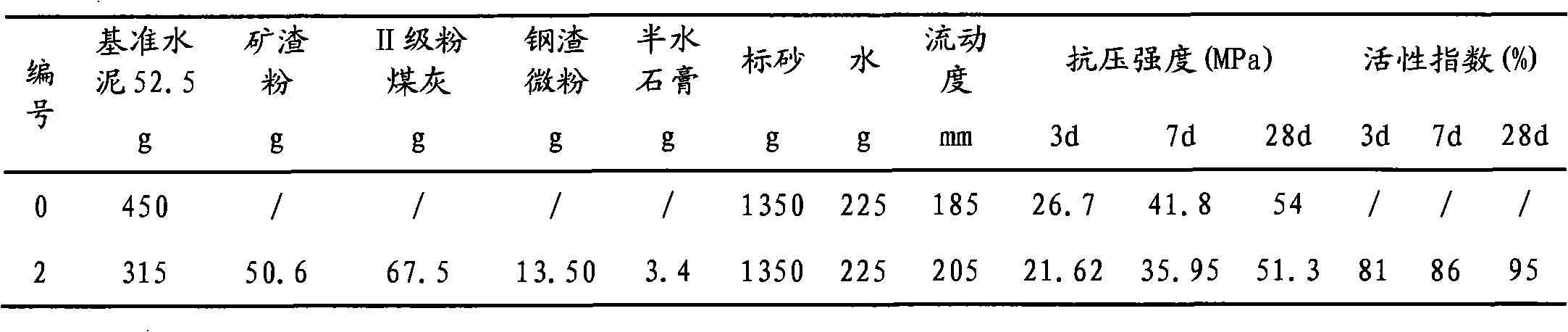

This invention provides a method and a device for processing animal testa substances including the following steps: 1, putting animal testa substances in a fermentation device, 2, putting 0.1-0.4% enzyme preparation with the function of degration albumen, a microbe preparation with the fermentation function and microbe fermentation base materials in the device to be mixed and fermented in seal, 3, filtering said fermentation liquid and separating solid and solution to be dried to get the product. A device is disclosed including a shell, a cover on the top of the shell, a mixing rod with mixing blades is set in the shell and one end of the rod extends outside of the rod through the cover, an outlet is set at the bottom and a valve is set at the outlet.

Owner:YUHUAN MARINE BIOCHEM

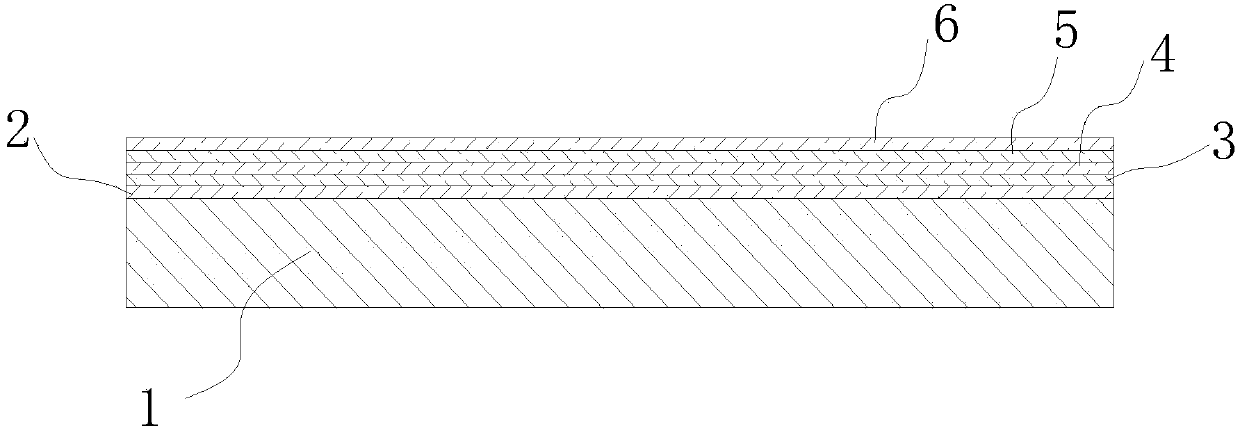

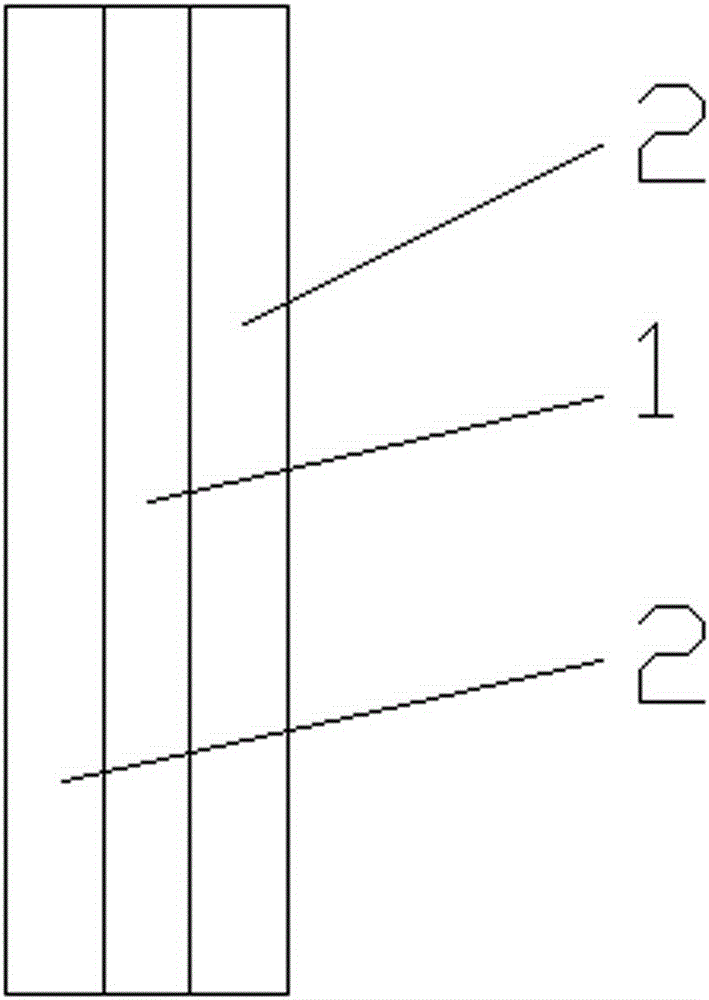

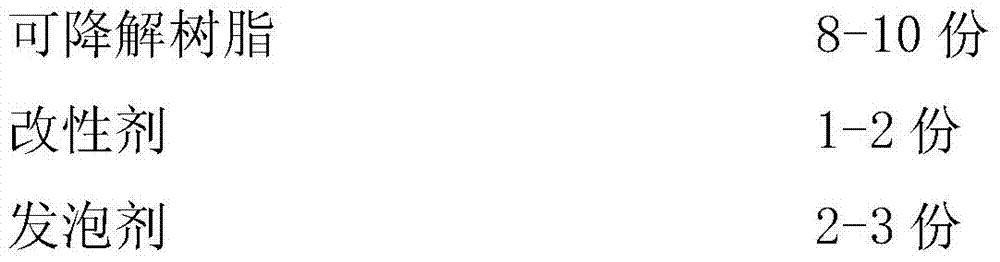

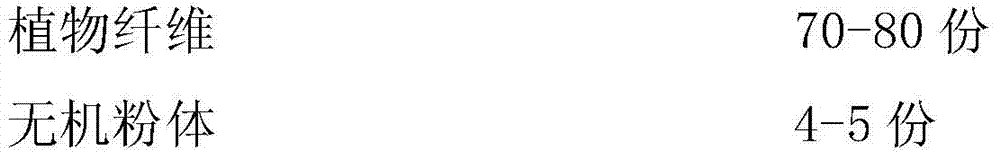

Degradable foam packaging material and its preparation method

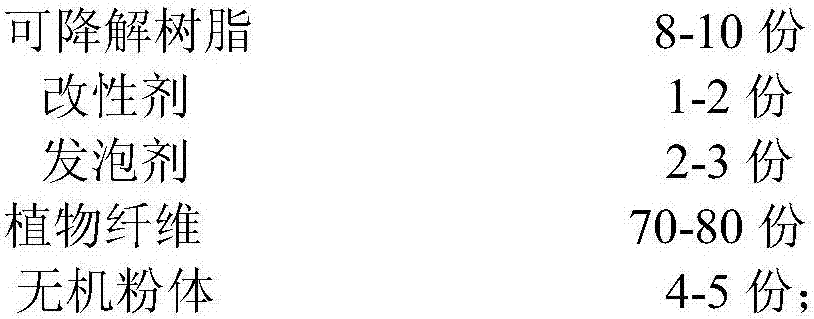

ActiveCN104312182AImprove wear resistanceSimplify processingFlexible coversWrappersVegetable fibersPolyresin

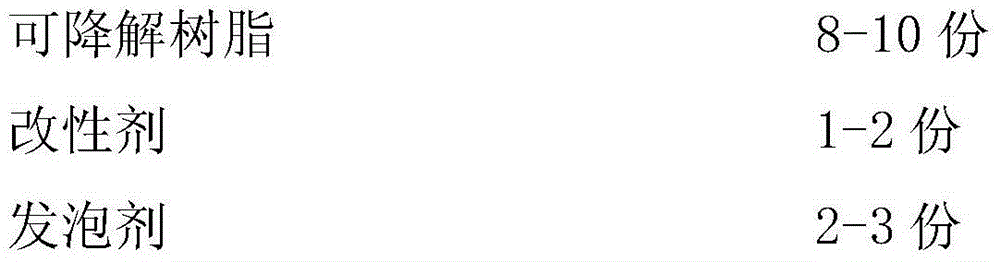

The invention discloses a degradable foam packaging material and its preparation method. The packaging material comprises, by weight, 8-10 parts of degradable resin, 1-2 parts of a modifier, 2-3 parts of a foaming agent, 70-80 parts of vegetable fiber and 4-5 parts of inorganic powder. The preparation method comprises the following steps: 1, preparing raw materials according to the above formula; 2, drying the vegetable fiber; 3, carrying out ultrafine treatment on the vegetable fiber, and preparing a modified vegetable fiber composite base material; 4, carrying out low temperature high shearing on the modified vegetable fiber composite base material; 5, pre-foaming the modified vegetable fiber composite base material; 6, carrying out foaming extrusion on the modified vegetable fiber composite base material; and 7, cooling and fixing to obtain the degradable foam packaging material. The degradable foam packaging material has the advantages of high strength, good toughness, low density, economy, environmental protection and the like.

Owner:江西禾尔斯环保科技有限公司

A decalcification process for old bittern in high calcium salt fields

ActiveCN104817096BSimple processReduce manufacturing costCalcium/strontium/barium sulfatesAlkali metal chloridesHigh concentrationSlurry

A decalcification technique of high-calcium old brine in a salt field includes the following steps: (1), dissolving mirabilite; (2), evenly mixing mirabilite mother liquid obtained in the step (1) with the high-calcium old brine in the salt field according to a molar ratio of Ca2+ to SO42- being 1: (1-1.2) for 1-24 hours to obtain slurry; (3), filtering; (4) washing and drying; (5), returning the decalcified old brine obtained in the step (3) to the sodium chloride salt field and continuing to evaporate the old brine. The decalcification technique has the advantages that sodium sulfate resources of a salt lake or nearby places are fully used for reacting with calcium sources in the high-calcium old brine to achieve decalcification of the old brine; technological process is simple and cost is low; the technique can be implemented directly in resource locations, circular brine mixing of high-concentration magnesium chloride brine after decalcification of the high-calcium old brine can be achieved, gypsum products can be produced, sodium sulfate minerals can be digested and local environment problems of the salt lake can be relieved.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

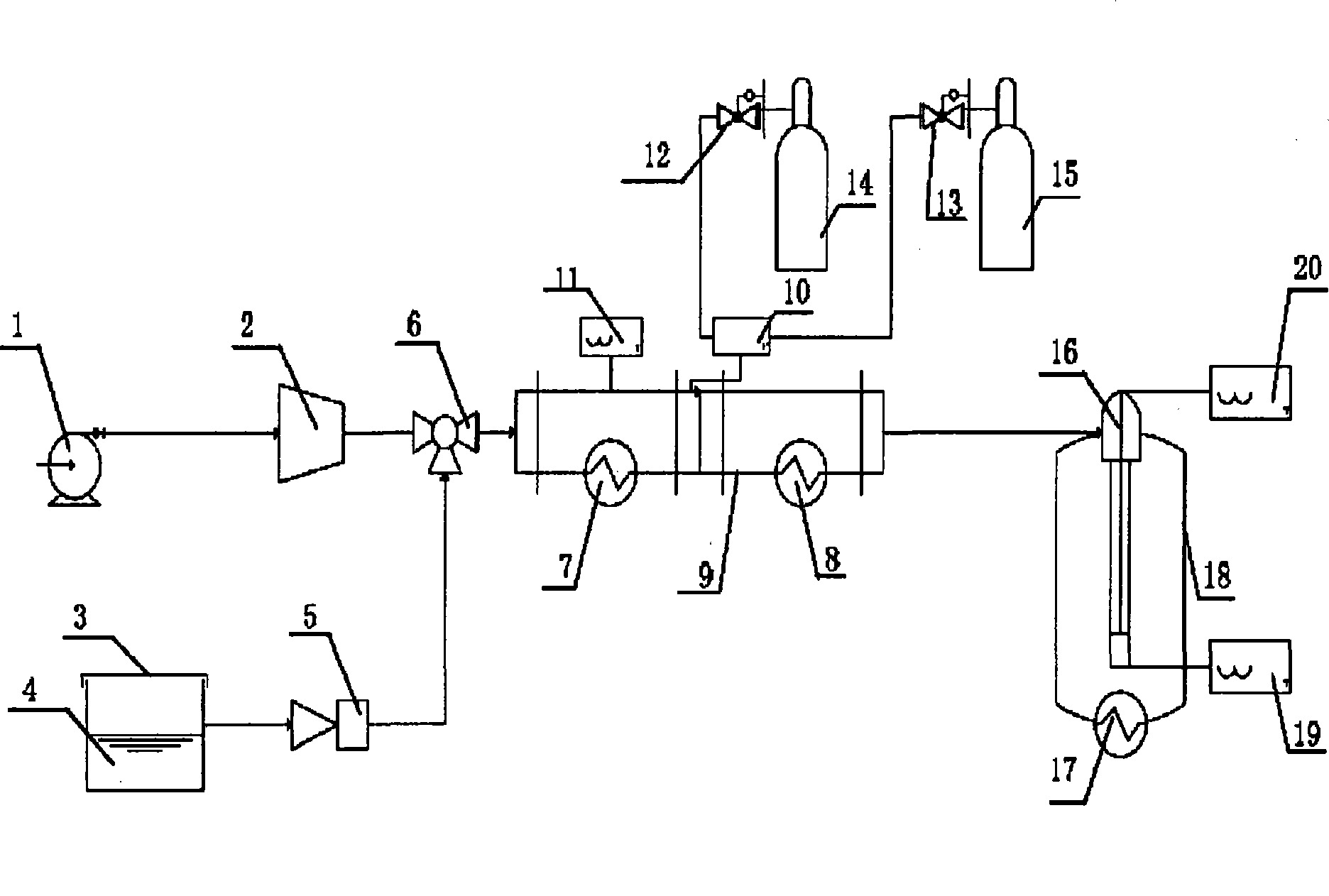

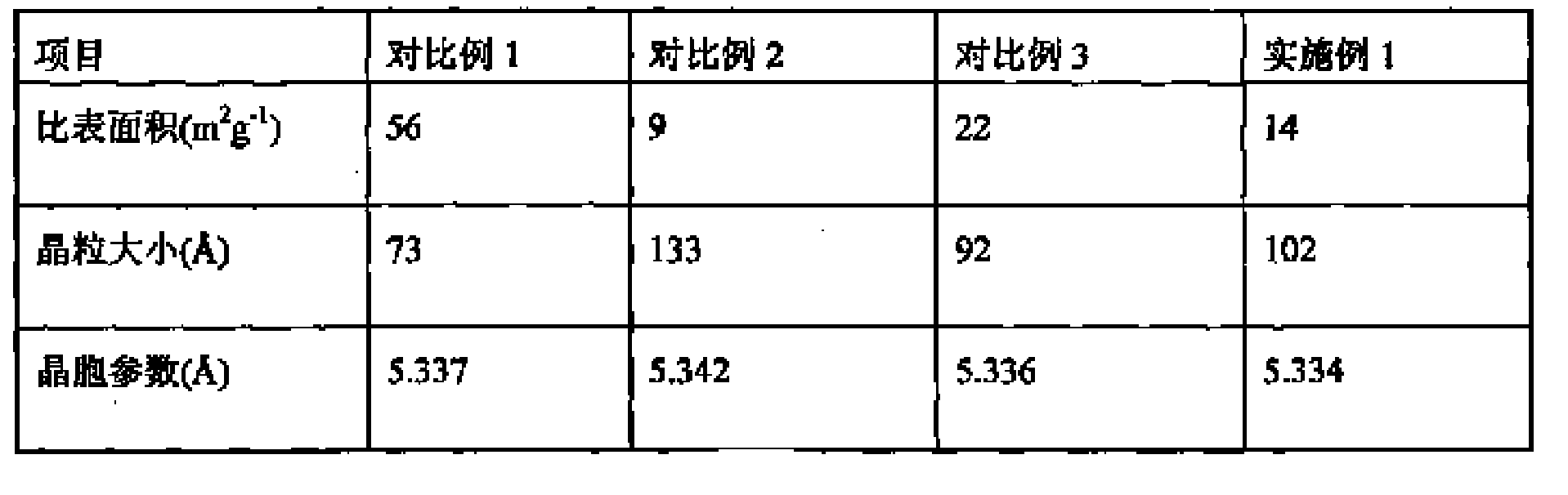

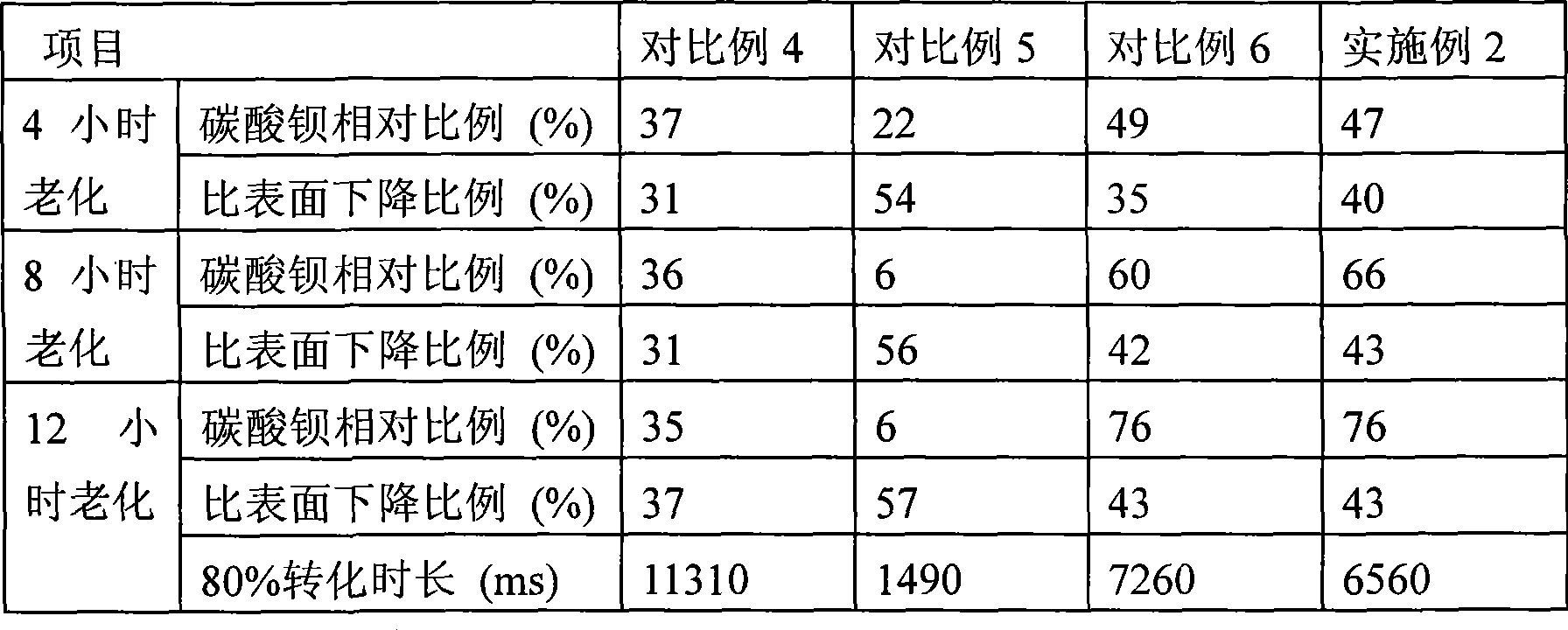

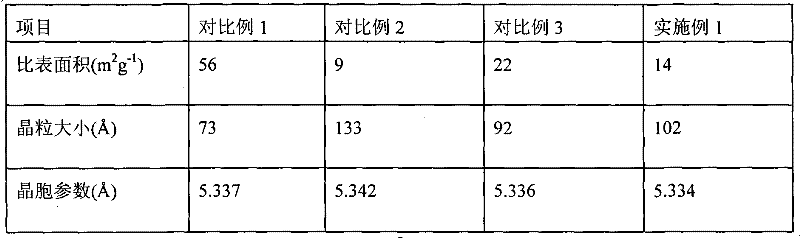

Forced aging apparatus and technique for motor vehicle vent gas purification catalysis material

InactiveCN101476998ANo emissionsImprove processing efficiencyChemical analysis using catalysisPreparing sample for investigationCeriumToxic material

The invention relates to a device and a process method for forcedly aging a motor vehicle tail gas purifying and catalyzing material. The process comprises: loading the motor vehicle tail gas purifying and catalyzing material into an aging reaction tube and heating the material; introducing an aged gas into a bed layer of a reactor catalyzing material for aging treatment for 5 to 20 hours at a temperature of between 400 to 1,300 DEG C; and taking out the aged catalyzing material, and testing the material. The aging device mainly comprises a gas path, an aging tube reactor and a temperature control component. The device and the method are used for carrying out service life investigation and activity screening on the motor vehicle tail gas purifying and catalyzing material containing at least one class of oxide corresponding to elements like cerium, zirconium, aluminum, barium and the like. The device and the method have the advantages of real and reliable test result, simple operation process, small operation risk, good repeatability and easy realization of engineering scale-up. Highly toxic waste gas, waste liquid and waste residue are not discharged in the process of processing so the invention meets the circular economy requirements.

Owner:TIANJIN UNIV

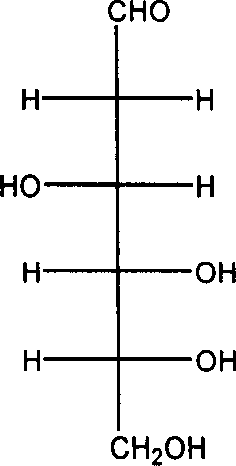

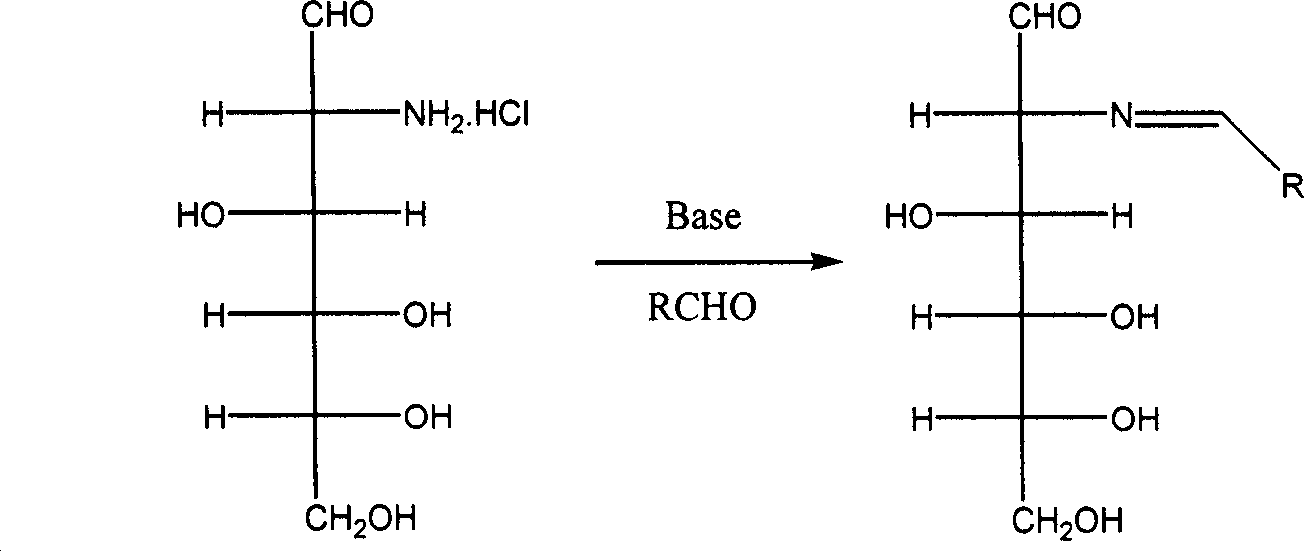

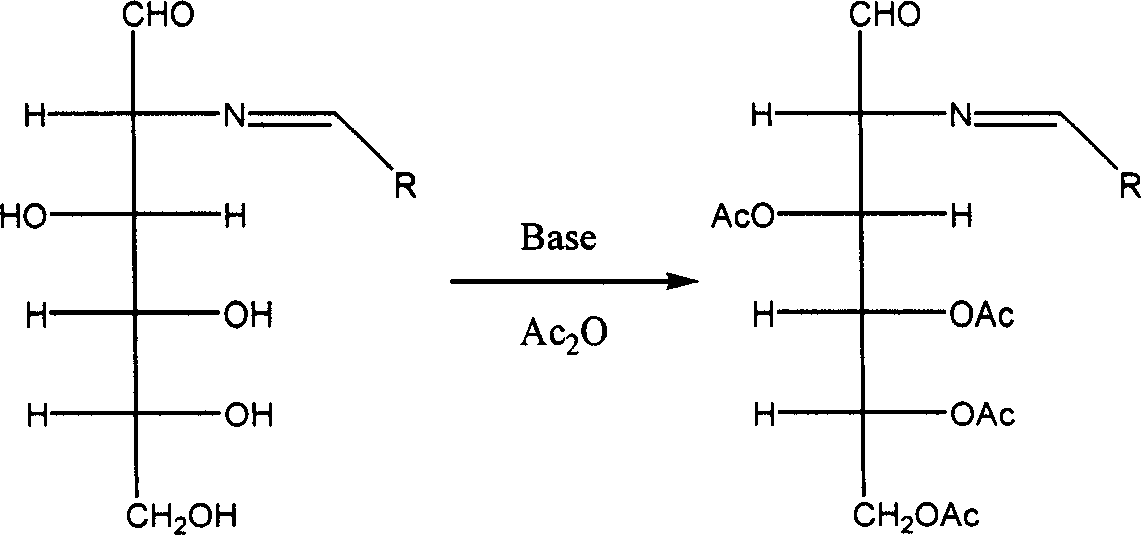

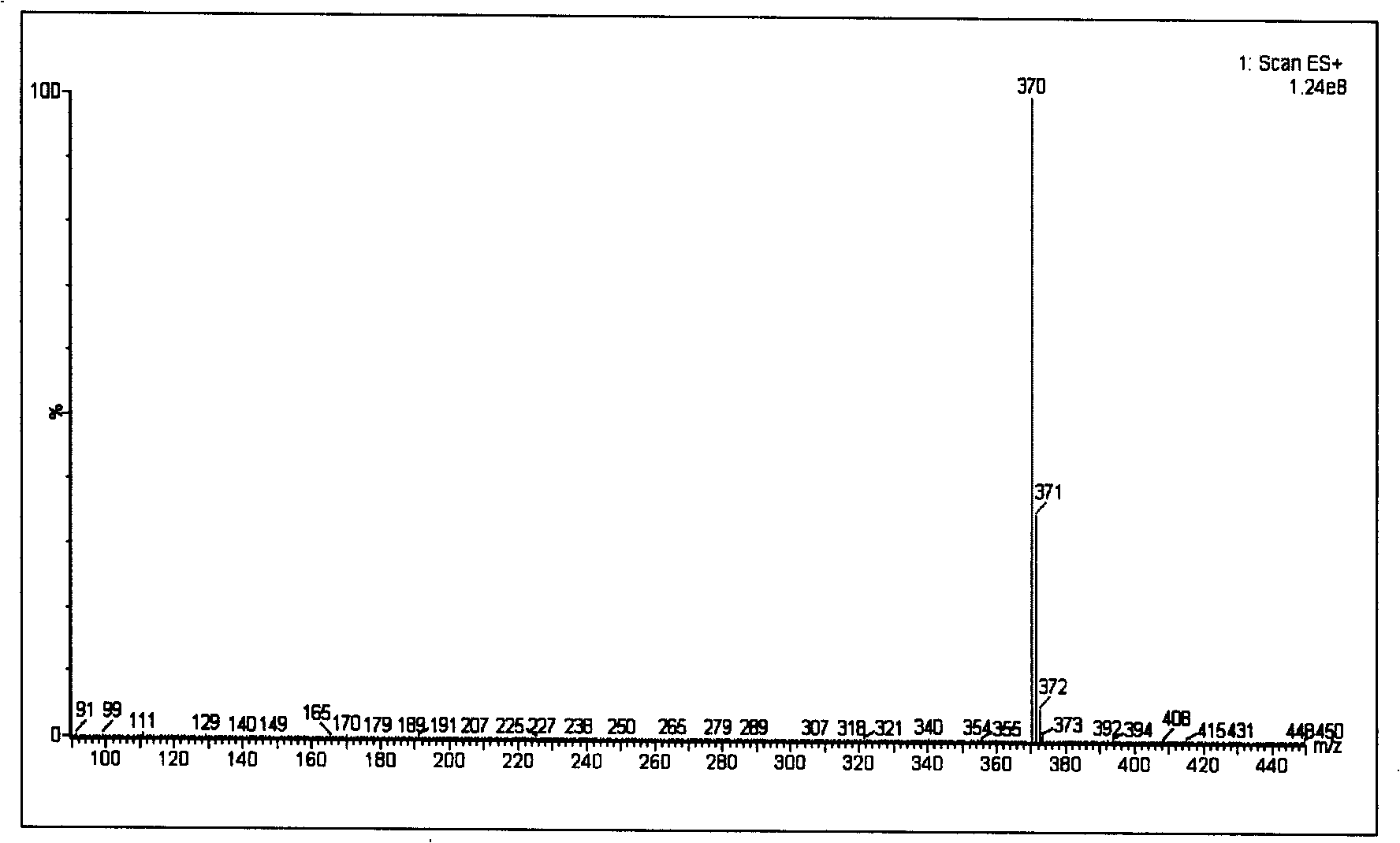

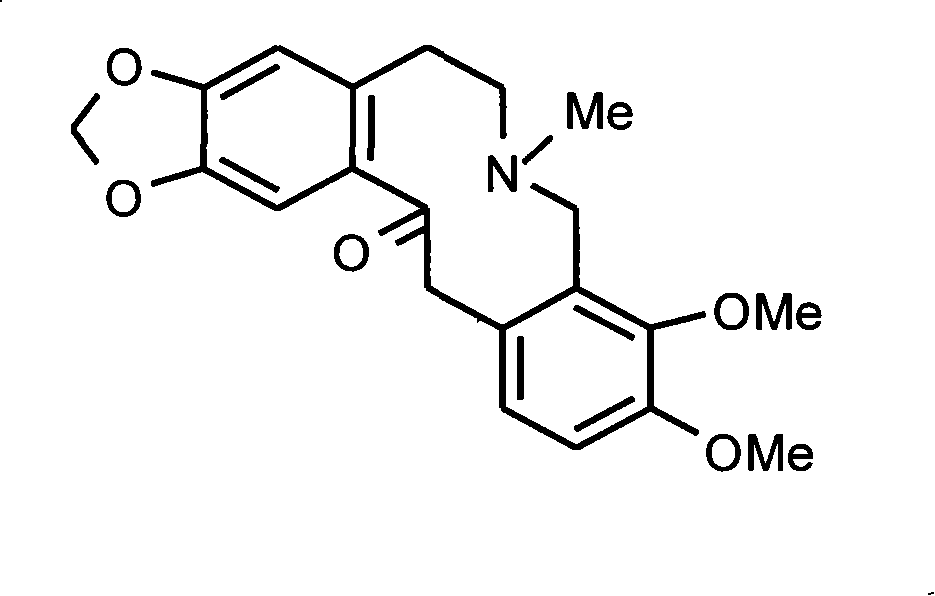

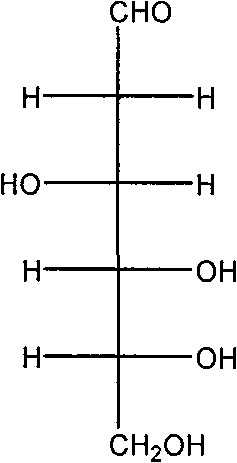

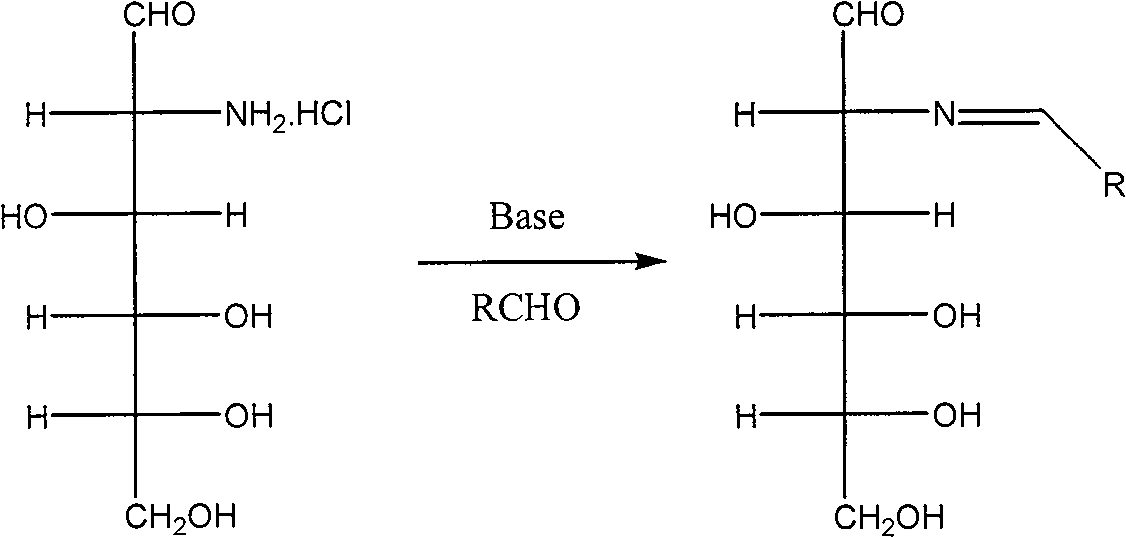

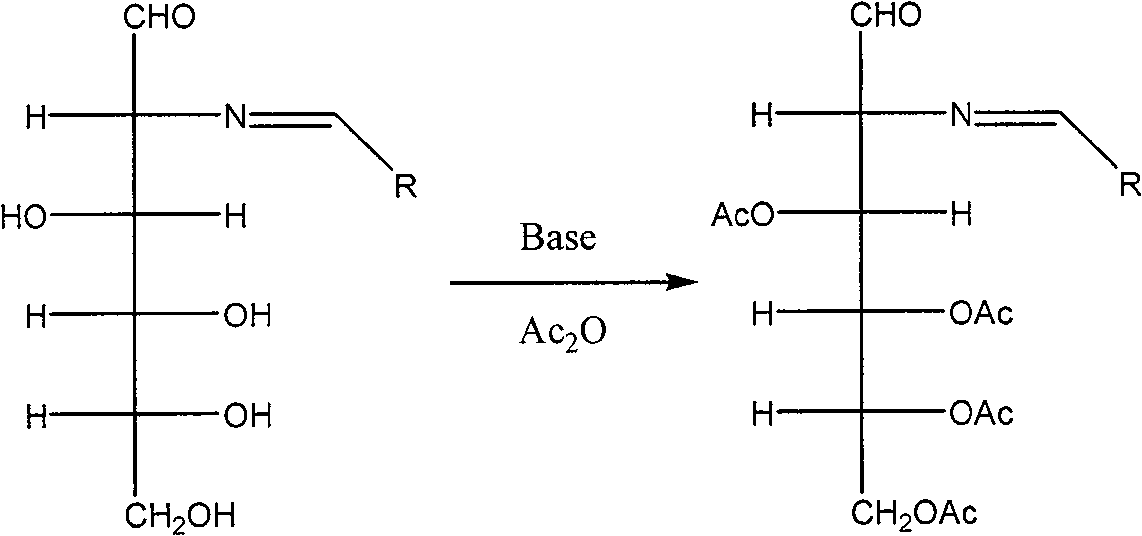

New method for preparing 2-deoxy-D-glucose

InactiveCN1775791AImprove performanceGood antiviral effectDeoxy/unsaturated sugarsD-Glucose2-Deoxy-D-glucose

The invention discloses a method of preparing 2-deoxidation-D-glucose. It solves the problems of the complex manufacturing technique and high cost for existing 2-deoxidation-D-glucose. The method includes the following steps: preparing 1.2-deoxidation-2-phenylenemethylamino-D-glucose; preparing 2.2-deoxidation-2- phenylenemethylamino-3,4,5,6-four-O-acetyl-D-glucose; preparing 4.2-deoxidation -2-chorine-3,4,5,6-four-O-acetyl-D-glucose; preparing 5.2-deoxidation-3,4,5,6- four-O-acetyl-D-glucose; preparing 6.2-deoxidation-D-glucose. The raw material of the method is far ranging, and low cost. It has great economic, social, and environment benefit.

Owner:YUHUAN MARINE BIOCHEM

Preparation method of degradable foam packing material

InactiveCN103819919AExtensive sources of raw materialsLight in massFlexible coversWrappersCorn starchAluminium

The invention discloses a preparation method of a degradable foam packing material. The preparation method comprises the following steps: 1) rubbing straw to prepare straw fibers; 2) adding 50-54 parts of straw fibers, appropriate amount of water, and 6-8 parts of a plant fiber modifier in a mixer for dispersing uniformly; 3) putting 42-46 parts of corn starch, 6-8 parts of silicon oxide powder, 12-14 parts of talcum powder and 6-8 parts of powdered aluminum into the mixer, heating to 60-70 DEG C, mixing uniformly to prepare a pasty material; 4) adding 200-210 parts of a 4-6% sodium hydroxide solution, and stirring at the same time; 5) coating the wall surface of a mold with 2-4 parts of an organic silicon releasing agent, filling the mold with the mixed slurry, continuously foaming and expanding for 16-18 minutes at the temperature of 125-135 DEGC; 6) drying at 100-110 DEG C to release the mold,so that the finished packing material is obtained.

Owner:WUXI HUANGSHENG PACKING PROD

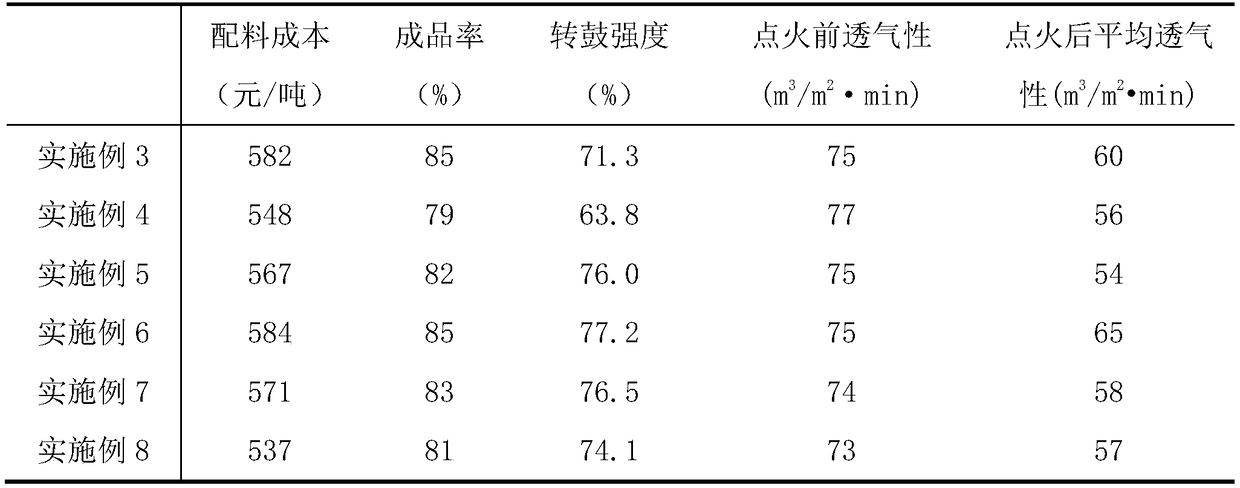

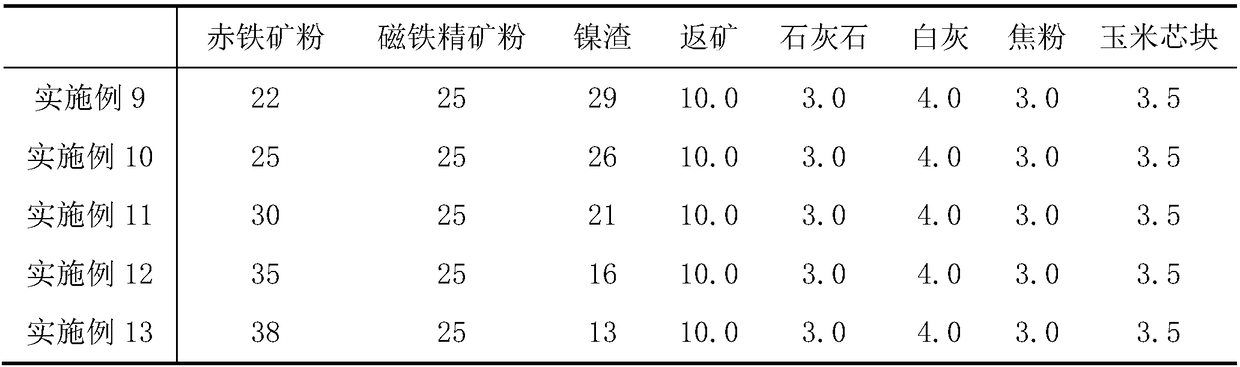

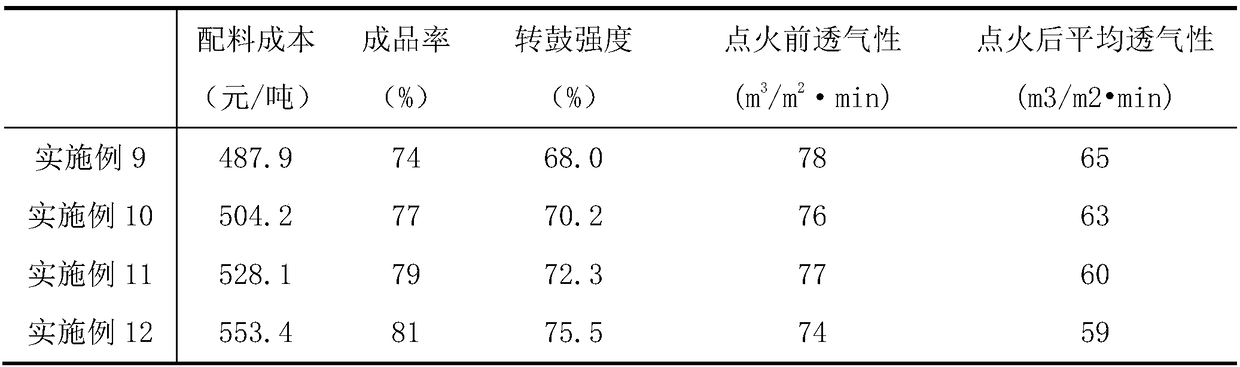

Method for preparing stainless steel production raw material sintered ore by using nickel slag

The invention discloses a method for preparing a stainless steel production raw material--sintered ore--by using nickel slag. The method comprises the following steps: batching; mixing and granulation; material distribution; sintering; cooling; sieving; etc. Raw materials used in the step of batching are composed of, by weight, 20 parts to 45 parts of magnetite powder, 20 parts to 40 parts of hematite powder, 10 parts to 30 parts of nickel slag, 2 parts to 4 parts of limestone, 3 parts to 5 parts of lime, 2 parts to 4 parts of coke powder, and 3 parts to 4 parts of corn cob pieces. According to the method, the nickel slag is used as a raw material for preparing the stainless steel production raw material--sintered ore, so the utilization rate of the nickel slag can be improved; the nickelslag is fully utilized and turned from the waste into the valuable; environmental problems caused by stacking of the nickel slag are avoided; the cost of the sintered ore used as the stainless steel production raw material is lowered; and the reuse of the nickel slag meets the requirements of circular economy.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Decalcification technique of high-calcium old brine in salt field

ActiveCN104817096ASimple processReduce manufacturing costCalcium/strontium/barium sulfatesAlkali metal chloridesHigh concentrationDecalcification Technique

A decalcification technique of high-calcium old brine in a salt field includes the following steps: (1), dissolving mirabilite; (2), evenly mixing mirabilite mother liquid obtained in the step (1) with the high-calcium old brine in the salt field according to a molar ratio of Ca2+ to SO42- being 1: (1-1.2) for 1-24 hours to obtain slurry; (3), filtering; (4) washing and drying; (5), returning the decalcified old brine obtained in the step (3) to the sodium chloride salt field and continuing to evaporate the old brine. The decalcification technique has the advantages that sodium sulfate resources of a salt lake or nearby places are fully used for reacting with calcium sources in the high-calcium old brine to achieve decalcification of the old brine; technological process is simple and cost is low; the technique can be implemented directly in resource locations, circular brine mixing of high-concentration magnesium chloride brine after decalcification of the high-calcium old brine can be achieved, gypsum products can be produced, sodium sulfate minerals can be digested and local environment problems of the salt lake can be relieved.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

Preparation method of double-faced compound warm-keeping and energy-saving wallboard

ActiveCN103029367AImprove sound insulationImprove flexural strengthWater-setting substance layered productElectricityBottom ash

The invention discloses a preparation method of a double-faced compound warm-keeping and energy-saving wallboard. The method comprises the following steps of mixing and stirring 50-70% of bottom ash of household garbage after the household garbage is burnt to generate electricity, 5-20% of milling fine sand, 5-15% of lime and 5-20% of water by mass percentage, obtaining hard slurry, injecting the hard slurry into a panel mold, placing a corresponding wire mesh, conducting three rolling procedures, steaming by high pressure, cooling, demolding, obtaining a panel, fixing the prepared panel on the two sides of a mold, mixing and uniformly stirring 30-50% of the bottom ash of the household garbage after the household garbage is burnt to generate the electricity, 10-20% of the lime, 10-25% of the milling fine sand, 10-20% of cement, 2-4% of plaster, 0.01-0.06% of aluminum powder and 5-20% of the water by mass percentage, obtaining slurry, injecting the slurry into a wallboard mold, stewing, steaming by the high pressure, cooling, demolding, and obtaining the wallboard.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

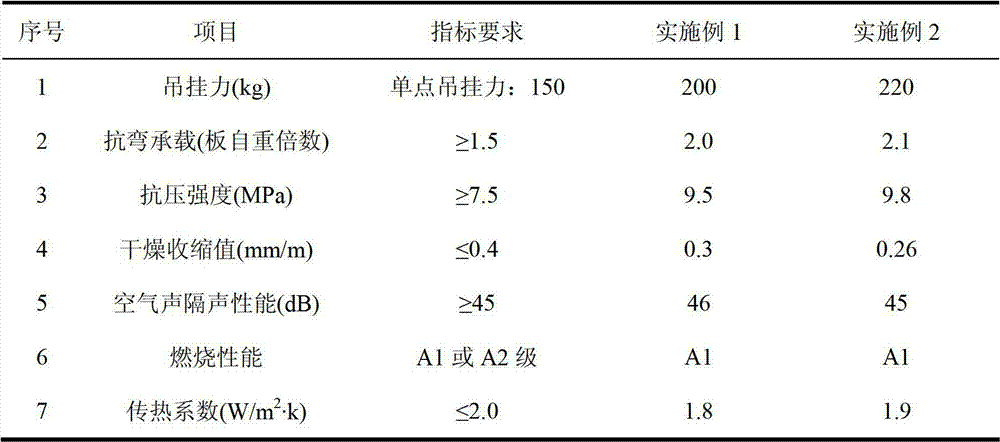

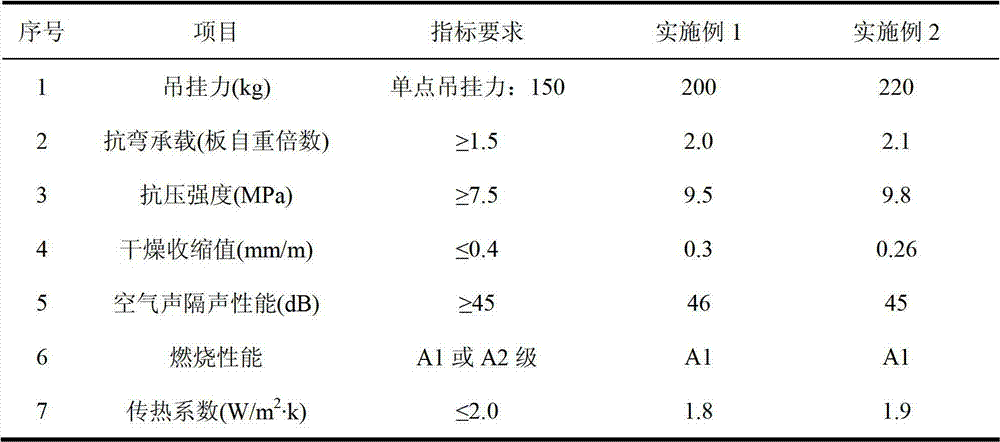

Calcium silicate board veneered light-weight wallboard and preparation method thereof

ActiveCN103541488AImprove sound insulationImprove flexural strengthConstruction materialCeramicwareCalcium silicateCircular economy

The invention relates to a calcium silicate board veneered light-weight wallboard and a preparation method thereof. The calcium silicate board veneered light-weight wallboard comprises an aerated concrete core veneer, wherein two maximum-area surfaces of the aerated concrete core veneer are adhered with calcium silicate boards, and the wallboard is finally prepared by sequentially preparing slurry, a steel reinforcement framework and the aerated concrete core veneer. The calcium silicate board veneered light-weight wallboard has favorable sound insulation performance, high bending strength and good nailing and hanging performances, can comprehensively meet the requirements for the functions of a wall body, creates advantages for environment friendliness, energy saving, waste utilization and circular economy, and is the optimal product obtained through wall material reformation at present so as to have favorable development prospects.

Owner:SHAOGUAN QUANCHENG IND TECH CO LTD

Apparatus and process method for forcibly aging vehicle tail gas purification catalytic material

InactiveCN107247114ANo emissionsImprove processing efficiencyChemical analysis using catalysisPreparing sample for investigationLiquid wasteCerium

The invention relates to a device and a process method for forced aging of catalytic materials for vehicle tail gas purification. The process is to put a vehicle exhaust gas purification catalytic material into the aging reaction tube and heat it; the aged gas is passed into the bed of the catalytic material in the reactor and aged at 400-1300°C for 5-20 hours; the aging-treated catalytic material is completed Take out the test. The aging device mainly includes three parts: gas circuit, aging tube reactor, and temperature control components. The invention is used for life investigation and activity screening of a vehicle tail gas purification catalytic material containing at least a certain type of oxides corresponding to elements such as cerium, zirconium, aluminum, barium and the like. The test results are true and reliable, the operation process is simple, the operation risk is small, the repeatability is good, the project scale-up is easy to realize, and the treatment process has no highly toxic waste gas, waste liquid, and waste residue discharge, which meets the requirements of circular economy.

Owner:桐城市宇洁机动车尾气检测有限公司

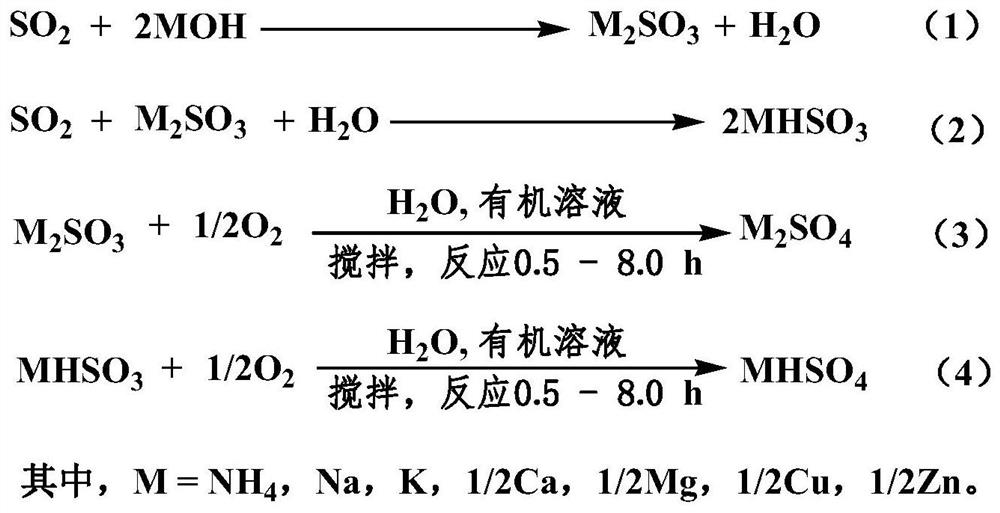

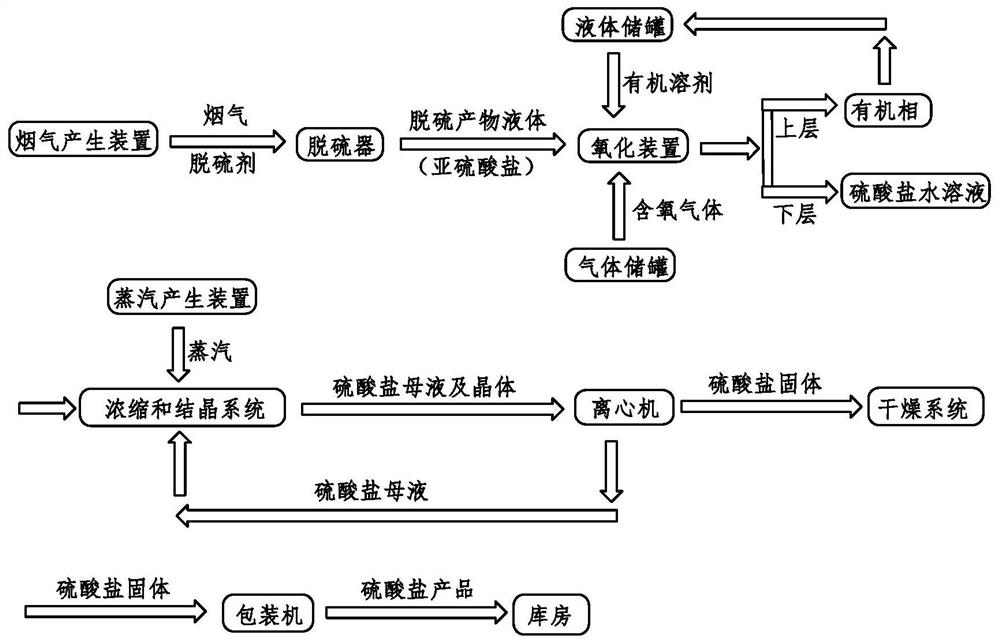

Oxidation method of sulfite or acidic sulfite or mixture thereof

PendingCN112010417AComply with circular economy requirementsImprove utilization efficiencyWater contaminantsChemical industrySulfite saltFlue gas

The invention provides an oxidation method of sulfite or acidic sulfite or a mixture thereof. The oxidation method comprises the following steps: introducing oxygen into an organic solution capable ofdissolving oxygen to oxidize an aqueous solution of sulfite or acidic sulfite or a mixture thereof, thereby preparing a sulfate product. The method is high in oxidation rate, can be applied to a comprehensive treatment technology of flue gas discharged in the coal industry, the petrochemical industry, the thermal power plant, the smelting industry and the like, and particularly relates to a post-treatment technology of flue gas desulfurization products and treatment of sulfite-containing wastewater generated in the industries of pesticides, printing and dyeing and the like. The method is lowin production equipment investment, energy-saving, time-saving, low in cost and convenient to operate, and can be applied to oxidation of sulfite aqueous solutions with different concentrations.

Owner:YUNNAN MINZU UNIV +1

Degradable foam packing material

InactiveCN103819922AWidely sourced and renewableComply with circular economy requirementsFlexible coversWrappersFiberFoaming agent

The invention discloses a degradable foam packing material. The packing material comprises the following ingredients in parts by weight: 100 parts of straw fiber, 80-86 parts of corn starch, 12-16 parts of silicon oxide powder, 24-28 parts of talcum powder, 10-16 parts of a plant fiber modifier, 5-9 parts of an organic silicon releasing agent, and 10-12 parts of a foaming agent, wherein the foaming agent is a reaction product of powdered aluminum and sodium hydroxide; the sodium hydroxide in the preparation process is a solution with the concentration of 4-6%.

Owner:WUXI HUANGSHENG PACKING PROD

Deodorant based on resource utilization

ActiveCN107320757AGood deodorizing effectIncrease resource consumptionDeodrantsChemistryCircular economy

The invention discloses a deodorant based on resource utilization. The deodorant is screenings of glass anti-mildew insulation powder with the particle size ranging from 60 mu m to 120 mu m. The deodorant has a good deodorant effect, can remove odors at any time like a common deodorant, requires no extra resource consumption and meets the requirement of cyclic economy.

Owner:南京汉旗新材料股份有限公司

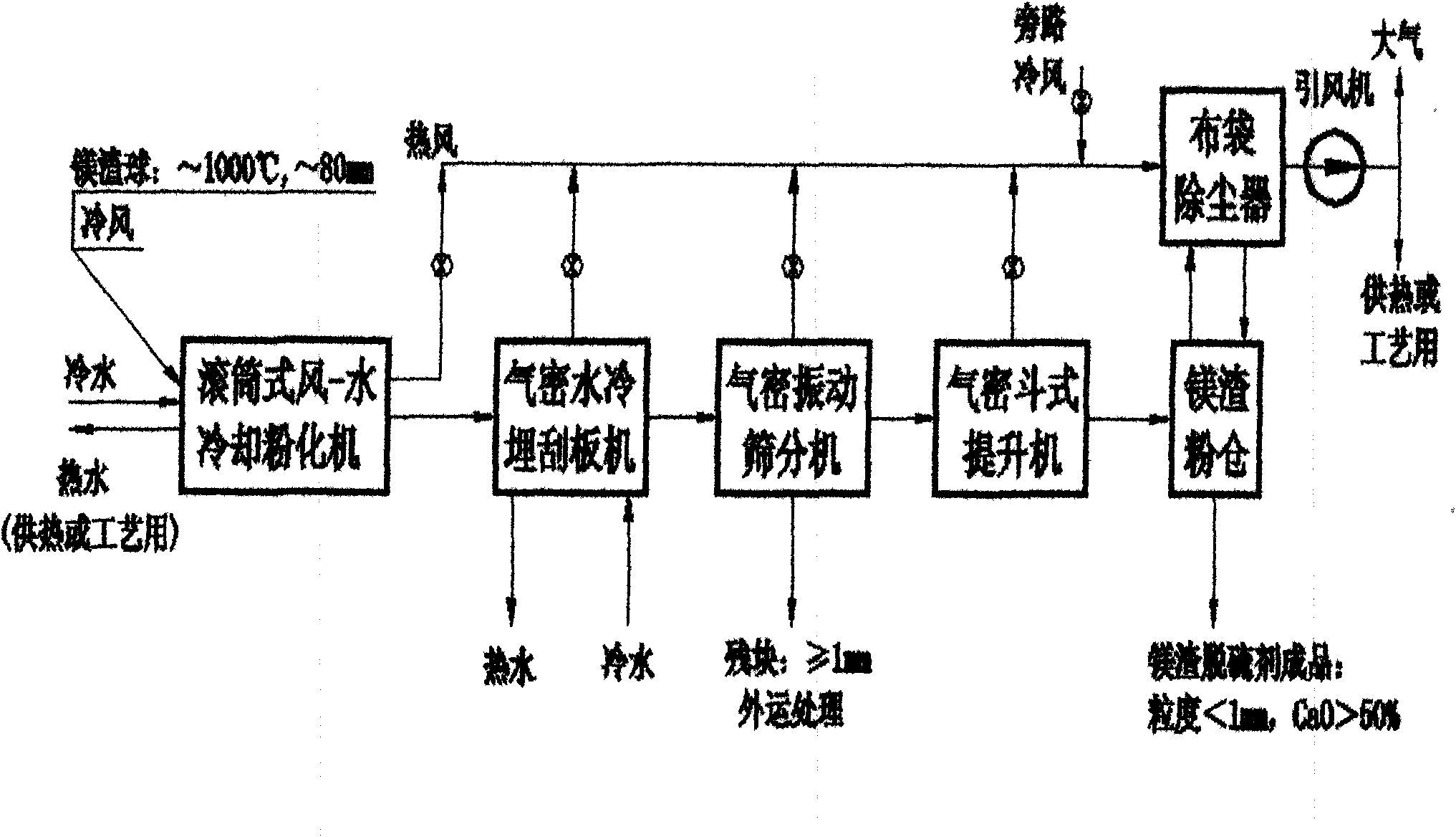

Process method for converting metal magnesium slag into desulphurizer of boiler

InactiveCN101791622BImprove cooling efficiencyEasy to handleSolid waste disposalDispersed particle separationSlagCrusher

Owner:山西猗顿生态环保股份有限公司

Sidewall panel for train carriage

ActiveCN104004420ACapable of deep drawingWith mass productionLiquid surface applicatorsInksAcrylic resinFireproofing

The invention relates to a sidewall panel for a train carriage, wherein the sidewall panel for the train carriage has the advantages that the deep drawing capability is achieved, multicolor patterns are formed on the surface, the sense of touch is good, and the scratch resistance is extremely high; the sidewall panel for the train carriage is suitable for decoration of the industries of indoor space, automobiles, trains and the like, no formaldehyde is released, the fireproofing grade reaches the A2 level, the sidewall panel for the train carriage can be used for large-scale indoor and outdoor decoration, the sidewall panel for the train carriage can be completely recycled after being used, no solid waste is produced, and the sidewall panel for the train carriage meets circular economy requirements. The sidewall panel for the train carriage comprises an aluminum substrate which is coated with priming paint, the priming paint is coated with finish paint, and the finish paint is coated with varnish. The varnish comprises, by weight, 55-60 parts of fluorocarbon resin, 15-20 parts of acrylic resin, 8-10 parts of fluorocarbon resin particles, 4-6 parts of isophoron or cyclohexanone and 3-6 parts of varnish additives.

Owner:JIANGSU PIVOT NEW DECORATIVE MATERIALS

Plant fiber foaming packaging material

The invention discloses a plant fiber foaming packaging material. According to the packaging material, a density is 0.23-0.28g / cm<3> and a yield limit is within 850-1000N / cm<2>. The packaging material comprises the following components in parts by weight: 100 parts of plant fiber, 35-37 parts of corn starch, 2-4 parts of sodium carboxymethylcellulose, 1-2 parts of polyoxyethylene, 6-8 parts of wollastonite in powder, 12-14 parts of talcum powder, 6-8 parts of plant fiber modifier, 2-4 parts of organic silicon release agent and 1-2 parts of polyamide polyurea.

Owner:WUXI HUANGSHENG PACKING PROD

A kind of preparation method of composite thermal insulation and energy saving lightweight concrete wall panel

ActiveCN103526872BImprove sound insulationImprove flexural strengthConstruction materialCalcium silicateThermal insulation

The invention relates to a method for preparing a composite thermal insulation and energy-saving lightweight concrete wallboard. slurry, prepare steel skeleton, prepare air-entrained concrete core board and finally can prepare wallboard. It has a good building energy-saving effect and meets the requirements of circular economy. The prepared wallboard has a built-in steel skeleton, has good sound insulation performance and high flexural strength, and has good nailing and hanging performance. The calcium silicate board veneer is light. High-quality wall panels fully meet the requirements of wall functions, and create favorable conditions for environmental protection, energy saving, waste utilization, and circular economy. It is the best product for wall material reform at present. Therefore, it has good development prospects.

Owner:SHAOGUAN QUANCHENG IND TECH CO LTD

Degradable foam packaging material and preparation method thereof

ActiveCN104312182BReduce manufacturing costLow priceFlexible coversWrappersFoaming agentVegetable fibers

The invention discloses a degradable foam packaging material and its preparation method. The packaging material comprises, by weight, 8-10 parts of degradable resin, 1-2 parts of a modifier, 2-3 parts of a foaming agent, 70-80 parts of vegetable fiber and 4-5 parts of inorganic powder. The preparation method comprises the following steps: 1, preparing raw materials according to the above formula; 2, drying the vegetable fiber; 3, carrying out ultrafine treatment on the vegetable fiber, and preparing a modified vegetable fiber composite base material; 4, carrying out low temperature high shearing on the modified vegetable fiber composite base material; 5, pre-foaming the modified vegetable fiber composite base material; 6, carrying out foaming extrusion on the modified vegetable fiber composite base material; and 7, cooling and fixing to obtain the degradable foam packaging material. The degradable foam packaging material has the advantages of high strength, good toughness, low density, economy, environmental protection and the like.

Owner:江西禾尔斯环保科技有限公司

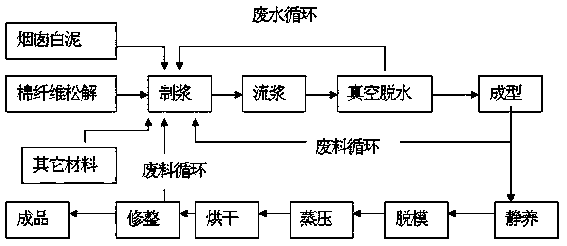

Chimney white mud and mixed cotton fiber reinforced calcium silicate sheet

A chimney white mud and mixed cotton fiber reinforced calcium silicate sheet is produced from the following raw materials by weight percent: 6-12 percent of mixed cotton fiber, 1-3 percent of fiberglass, 15-20 percent of the chimney white mud, 35-46.04 percent of quartz, 20-30 percent of common silicate cement and 1-2 percent of expanded perlite. The chimney white mud and mixed cotton fiber reinforced calcium silicate sheet has the advantages as follows: with the comprehensive utilization of the chemical white mud and recovered waste cotton tyre, the reuse value of the industrial and life waste materials is fully achieved to produce the chimney white mud and mixed cotton fiber reinforced calcium silicate sheet; the strength is high, the appearance is beautiful, and the cost is lower; not only is the problem about the comprehensive utilization of the industrial desulfurized gypsum and waste cotton tyre solved, but also the production cost of the calcium silicate sheet is lowered, the method which is reliable in technique, economical, feasible, and used for comprehensively utilizing waste resources is developed, and both the environment benefit and economical benefit are realized.

Owner:LIUZHOU JIAREN PLATE IND +1

Preparation method of double-faced compound warm-keeping and energy-saving wallboard

ActiveCN103029367BImprove sound insulationImprove flexural strengthWater-setting substance layered productElectricityBottom ash

The invention discloses a preparation method of a double-faced compound warm-keeping and energy-saving wallboard. The method comprises the following steps of mixing and stirring 50-70% of bottom ash of household garbage after the household garbage is burnt to generate electricity, 5-20% of milling fine sand, 5-15% of lime and 5-20% of water by mass percentage, obtaining hard slurry, injecting the hard slurry into a panel mold, placing a corresponding wire mesh, conducting three rolling procedures, steaming by high pressure, cooling, demolding, obtaining a panel, fixing the prepared panel on the two sides of a mold, mixing and uniformly stirring 30-50% of the bottom ash of the household garbage after the household garbage is burnt to generate the electricity, 10-20% of the lime, 10-25% of the milling fine sand, 10-20% of cement, 2-4% of plaster, 0.01-0.06% of aluminum powder and 5-20% of the water by mass percentage, obtaining slurry, injecting the slurry into a wallboard mold, stewing, steaming by the high pressure, cooling, demolding, and obtaining the wallboard.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

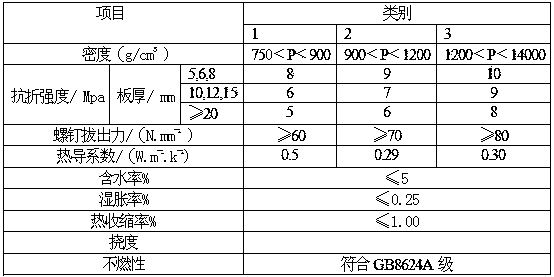

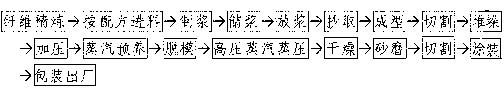

Carbide slurry fly ash fiber-reinforced architectural flat plate and manufacturing method thereof

ActiveCN102584120BLow costSmall coefficient of shrinkage deformationSolid waste managementCeramic shaping apparatusCalcium silicateCellulose fiber

The invention discloses a carbide slurry fly ash fiber-reinforced architectural flat plate and a manufacturing method thereof. The carbide slurry fly ash fiber-reinforced architectural flat plate comprises the components in percentage by weight as follows: 36 to 45 percent of carbide slurry, 42 to 48 percent of fly ash, 6 to 8 percent of cement, 5 to 8 percent of quartz sand, 6.5 to 9 percent of cellulose fiber and 1 percent of poly-acetamide. The manufacturing method of the carbide slurry fly ash fiber-reinforced architectural flat plate comprises the following steps: step I, fiber refinement; step II, material feeding and pulping according to a formula; III, pulp storage, pulp discharge, pick-up and forming; step IV, processing forming; and step V, coating and packaging. The invention has the advantages that by utilizing local industrial waste namely the carbide slurry and the fly ash as main raw materials and utilizing the cellulose fiber as a reinforcing material, the architectural flat plate which has a shrinkage deformation coefficient larger than that of an ordinary calcium silicate plate, and better fireproof performance is produced; the radioactivity measured value of the architectural flat plate is 10 to 20 percent of the minimum value allowed by a national regulation, so that the architectural flat plate belongs to green environmentally-friendly products; and not only the production process satisfies the requirement of circular economy, but products are plates for the fields of wall bodies, ceilings and architectural acoustics, which satisfy the requirements of componentization, assembly and dry work for architectural products, so that the architectural flat plate belongs to high-level architectural material products in the architectural products.

Owner:TANGSHAN SHIERDE BUILDING MATERIAL

A deodorant based on resource utilization

ActiveCN107320757BEasy to deodorizeNo need to increase resource consumptionDeodrantsProcess engineeringDeodoriser

Owner:南京汉旗新材料股份有限公司

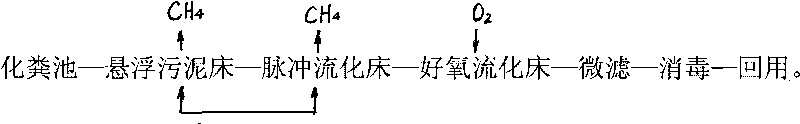

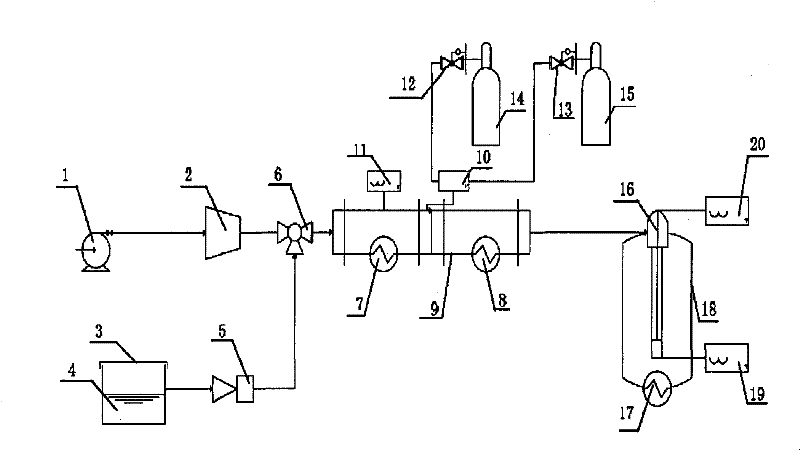

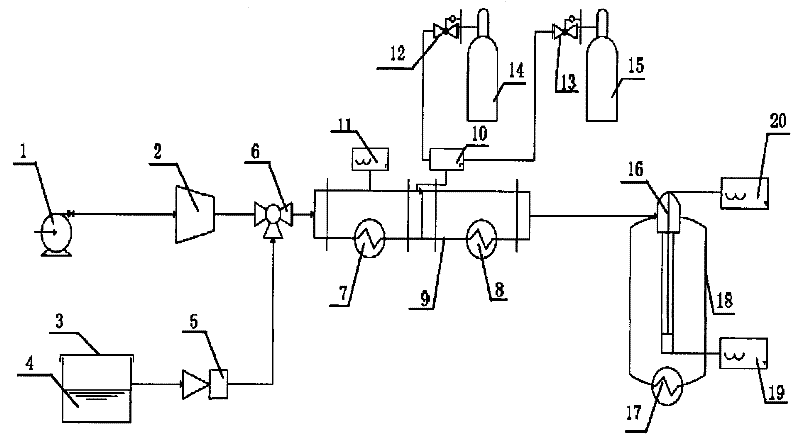

Micro-sized building block type recycled water treatment equipment

InactiveCN101717167AImprove processing efficiencySmall footprintTreatment using aerobic processesUltrafiltrationCycloneWater storage tank

The invention is a micro-sized building block type recycled water treatment equipment, which comprises a suspend sludge bed, an impulse fluidized bed, an aerobic fluidized bed and a recycled water storage tank, wherein the suspend sludge bed is provided with a sewage water inlet in which a cloth hydrophone , an exaltation water pump and a water circulating pump are arranged. An impulse generator is arranged in the impulse fluidized bed which is filled with suspend biological padding; the exaltation water pump is arranged at the bottom of the impulse fluidized bed; the recycled water storage tank is positioned at the lower part of the impulse fluidized bed, and a cyclone mixer is arranged in the recycled water storage tank. The aerobic fluidized bed is arranged on the impulse fluidized bed, and a microstrainer and a water-jet device are arranged in the aerobic fluidized bed. A water jet pump is arranged outside the aerobic fluidized bed. The invention adopts two-stage anaerobic and a group of anaerobic-aerobic four-stage biological treatment technologies so as to be effective in processing all pollutants. The equipment needs small field occupation and has simple technology. The equipment can treat 8 to 12 cubic meters of sewage water daily with the occupation of 1 square meter and can recycle methane, which conform to the requirements of recycling economy.

Owner:云南天兰环保科技开发有限公司 +1

Forced aging apparatus and technique for motor vehicle vent gas purification catalysis material

InactiveCN101476998BNo emissionsImprove processing efficiencyChemical analysis using catalysisPreparing sample for investigationCeriumToxic material

Owner:TIANJIN UNIV

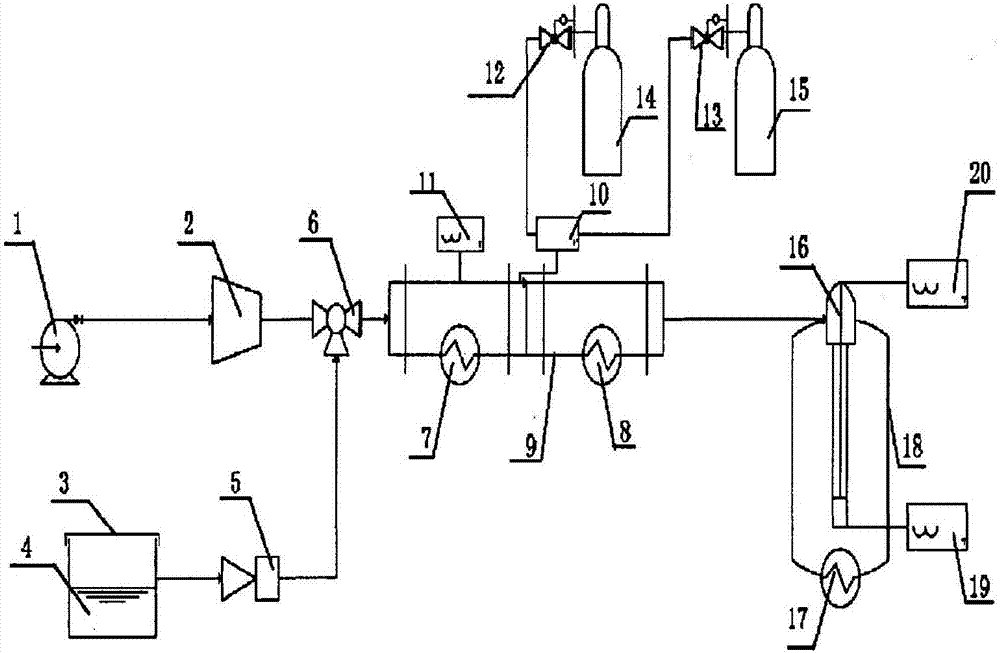

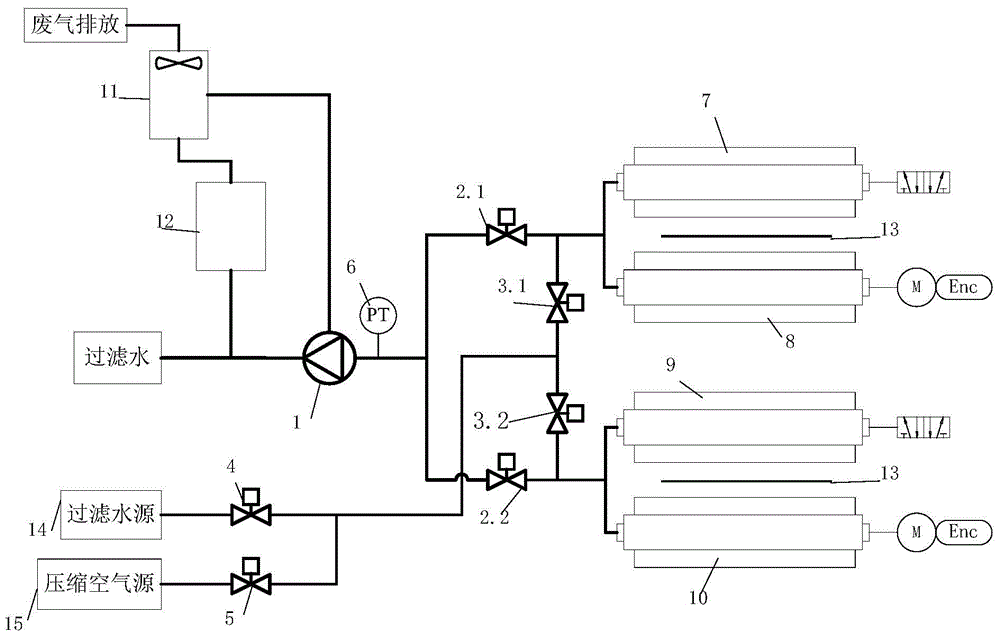

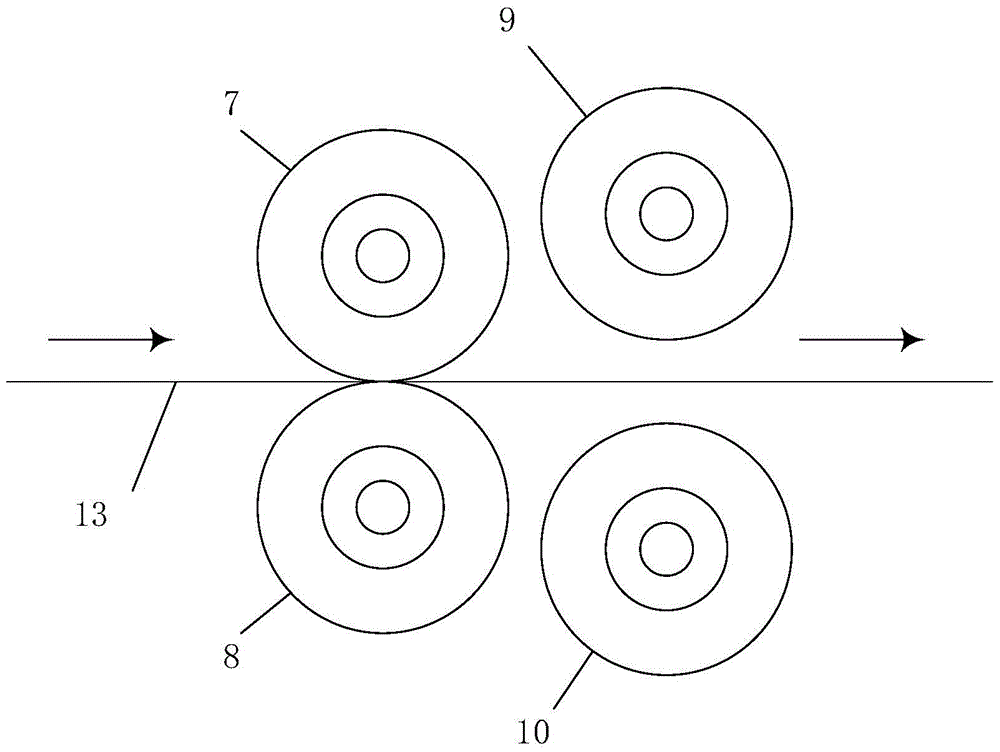

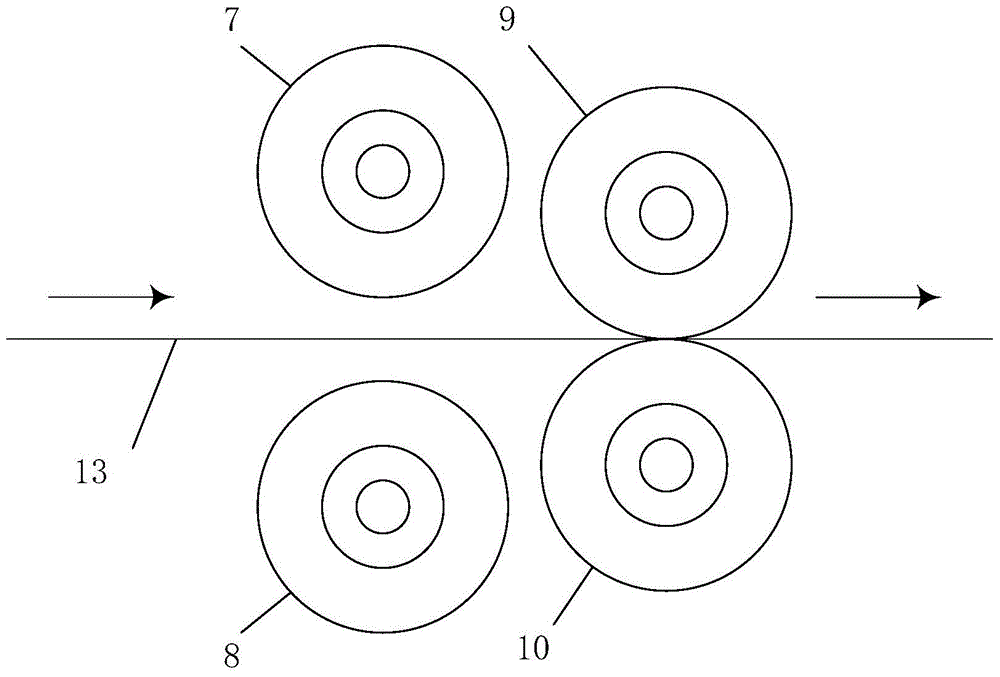

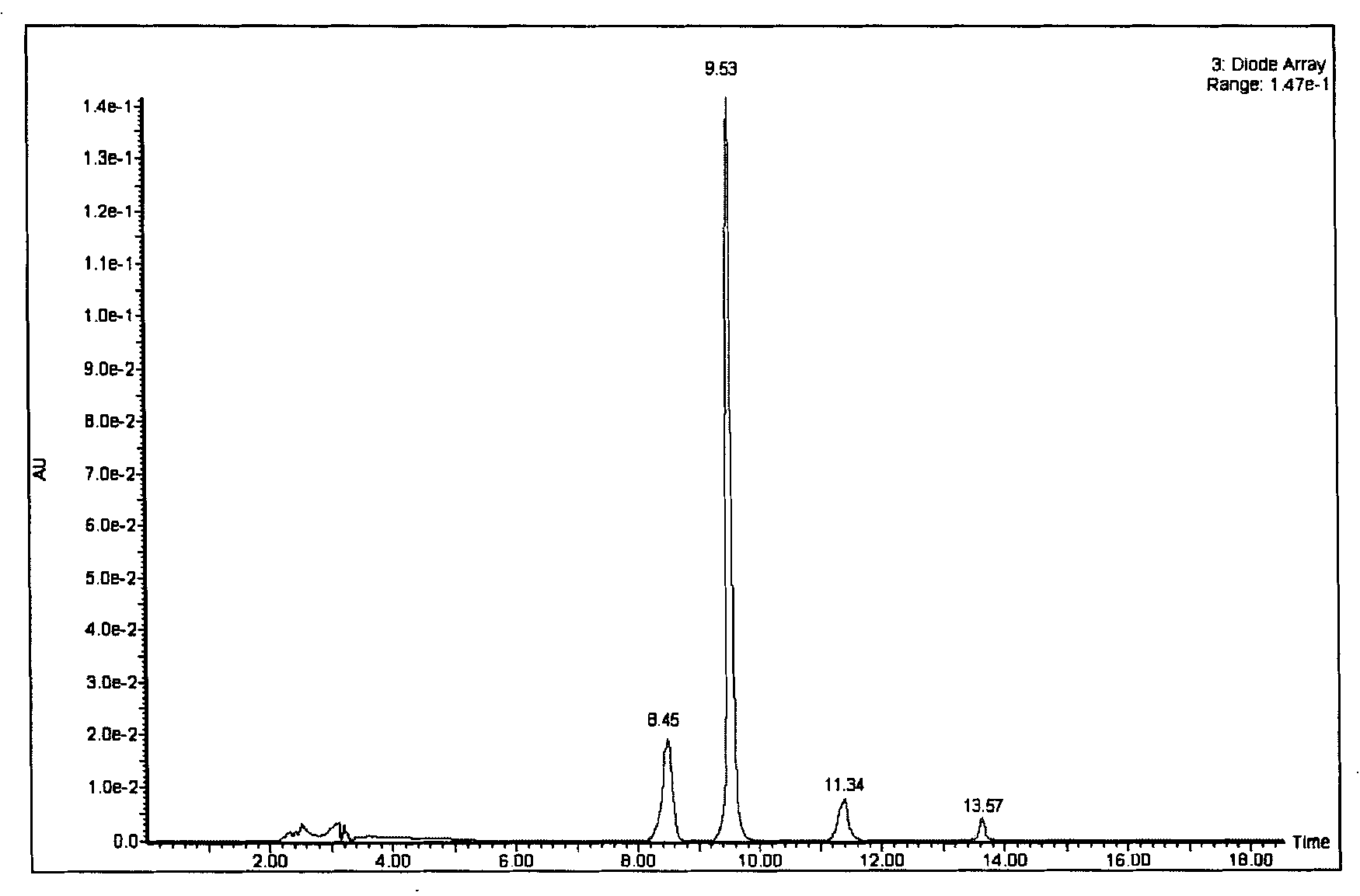

Cold-rolled strip vacuum cleaning system and its control method

ActiveCN105080983BReduce media consumptionReduce labor intensityWork treatment devicesMetal rolling arrangementsWater sourceStrip steel

The invention discloses a vacuum cleaning system for cold-rolling strip steel. The vacuum cleaning system comprises a vacuum pump, a first vacuum roller, a second vacuum roller, a first vacuum roller suction stop valve, a second vacuum roller suction stop valve, a first vacuum roller back-washing stop valve, a second vacuum roller back-washing stop valve, a back-washing filtered water stop valve and a converse-blowing compressed air stop valve. The first vacuum roller suction stop valve is located on a pipeline between the first vacuum roller and the vacuum pump. The second vacuum roller suction stop valve is located on a pipeline between the second vacuum roller and the vacuum pump. The back-washing filtered water stop valve is located on a pipeline between a filtered water source and the first vacuum roller. The converse-blowing compressed air stop valve is located on a pipeline between a compressed air source and the first vacuum roller. The first vacuum roller back-washing stop valve is installed on a pipeline between the back-washing filtered water stop valve and the first vacuum roller. The vacuum cleaning system for the cold-rolling strip steel can conduct cleaning and dehumidifying treatment on the surface of the strip steel continuously, and meanwhile the roller replacing frequency is reduced.

Owner:WISDRI ENG & RES INC LTD

Biomass acid material and preparation method thereof

The invention discloses a biomass acid material which is obtained through reaction of a biomass material and aldehyde acid, wherein the biomass material contains one or more of active groups, namely hydroxyl, amino, an aldehyde group or an ester group. According to the biomass acid material, leftover materials of natural plant resources are utilized, so that additional resource consumption is not needed and the biomass acid material meets the circular economy requirement.

Owner:南京汉旗新材料股份有限公司

Extraction method for preparing high-purity allocryptopine

ActiveCN101362766BIncrease contentHigh purityOrganic chemistryCardiovascular disorderFiltrationDistillation

The invention relates to a method for preparing and extracting high-purity allocryptopine. An initial extract is obtained by making use of ethanol to carry out refluxing, extraction and drying by distillation on natural papaveraceae plant; most alkaloid of the initial extract is subsided out in acidity alcohol, the pH value of the solution is adjusted to 7.5-8.5 by sig water and then to 9.5-10.5 after filtration, filtration is carried out again and filter residue is a crude extract; the crude extract is carried out refluxing treatment by ethyl acetate and methanol and filtered; the high-content allocryptopine monomer is obtained after the recrystallization of residue obtained from the filtrate by decompression and drying by distillation in methanol or chloroform-methanol or anhydrous alcohol. The method expands the scale of raw materials for extracting allocryptopine and provides a new economic and feasible way for preparing high-purity allocryptopine monomer. The method applies raw materials which are available, has simple and easy separation and purification technique and relatively low cost and is suitable for mass production.

Owner:湖南省中药提取工程研究中心有限公司

New method for preparing 2-deoxy-D-glucose

InactiveCN100572387CWide variety of sourcesLow priceDeoxy/unsaturated sugarsGlucose polymersD-Glucose

Owner:YUHUAN MARINE BIOCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com