Carbide slurry fly ash fiber-reinforced architectural flat plate and manufacturing method thereof

A technology of calcium carbide mud and fly ash, which is applied in the field of completely utilizing waste to produce high-quality building slabs and its manufacturing, can solve the problems of easy deformation of slabs, increase costs, and fear of tides, and achieve excellent performance, low cost, and simple production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

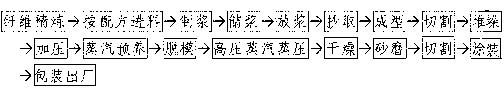

[0023] see figure 1 10% of cellulose fiber, 39.5% of calcium carbide mud, 43% of fly ash, 4% of cement, 3% of wollastonite, and 0.5% of chopped glass fiber are taken respectively in the present embodiment; first, the cellulose fiber is directly put into pulping In the vat, under the action of circulating water and debonder, it is dispersed into single fibers, and the natural color cellulose fibers that have been refined into the degree of percussion (°SR) 60-70 are mixed in turn in the pulping vat, and then mixed according to the proportion Add chopped glass fiber, calcium carbide mud, fly ash, and wollastonite under the action of the beater to make a slurry with a concentration of 10-14% and send it to the slurry storage tank. Function Send the slurry to the plate making machine to make slabs, after forming, cutting, stacking, pressurizing, steam curing in the steam curing room at 60-95°C for 4-6 hours, demoulding, and using 0.9-1.0Mpa steam Steam under pressure for 18 hours...

Embodiment 2

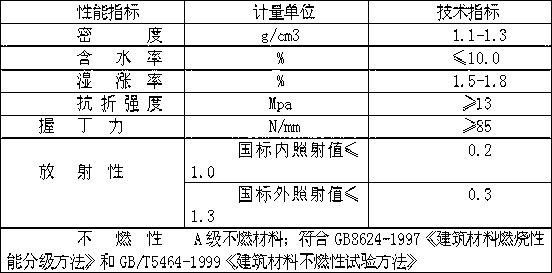

[0025] The present embodiment gets respectively 7% of cellulose fiber, 27% of calcium carbide mud, 18% of cement, 35% of fly ash, 8% of quartz sand, 5% of wollastonite, and makes carbide mud fly ash according to the steps of embodiment 1 Fiber reinforced building slabs. The properties of the plates are shown in Table 1.

Embodiment 3

[0027] The present embodiment gets respectively 8.5% of cellulose fiber, 40% of calcium carbide mud, 4% of cement, 38% of fly ash, 5% of quartz sand, and 4.5% of wollastonite, and the calcium carbide mud fly ash is made according to the steps of embodiment 1. Fiber reinforced building slabs. The properties of the plates are shown in Table 1.

[0028] Table 1 Performance indicators obtained from the test

[0029]

[0030] It can be seen from Table 1 that the calcium carbide mud fly ash fiber-reinforced building slab product of this embodiment has been tested many times, and its main technical indicators are: density 1.15g / cm3, moisture content 10%, flexural strength 13Mpa, wet expansion Rate 0.16%, holding force 85N / mm, I non-combustibility class A, radioactive (national standard: internal radiation ≤ 1.0, external radiation ≤ 1.3), internal radiation measured value 0.2, external radiation measured value 0.3; it does not contain any harmful substances, radioactive The meas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com