Micro-sized building block type recycled water treatment equipment

A processing equipment and building block technology, applied in the direction of sterilization/microdynamic water/sewage treatment, biological water/sewage treatment, multi-stage water/sewage treatment, etc. problem, achieve high processing efficiency, high processing efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

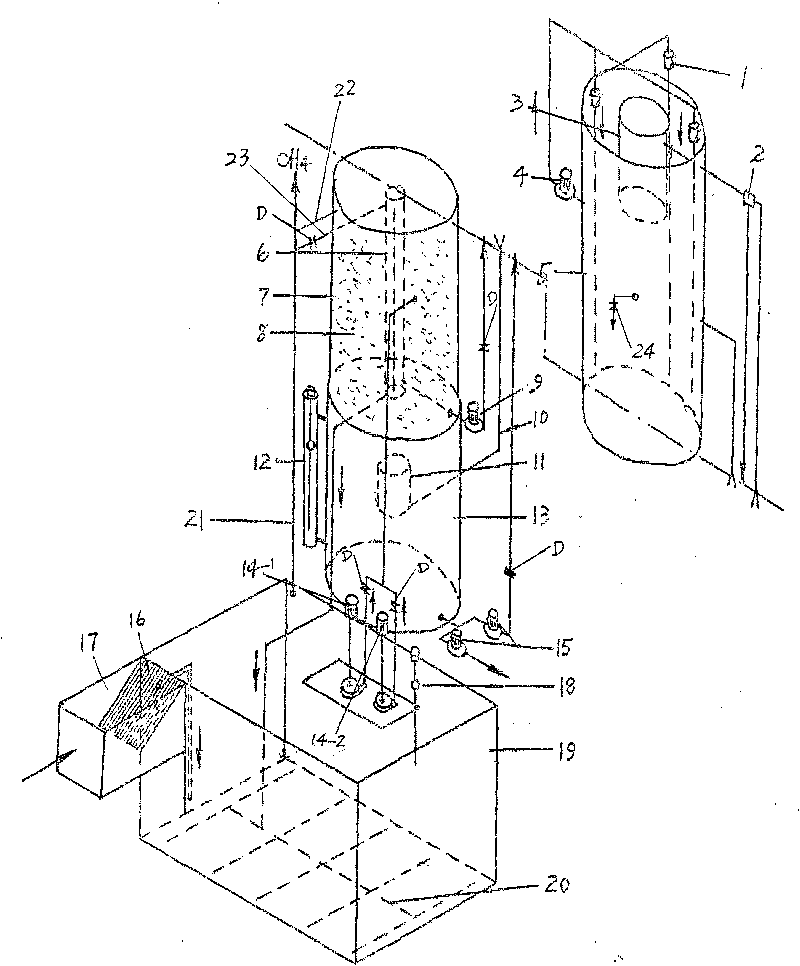

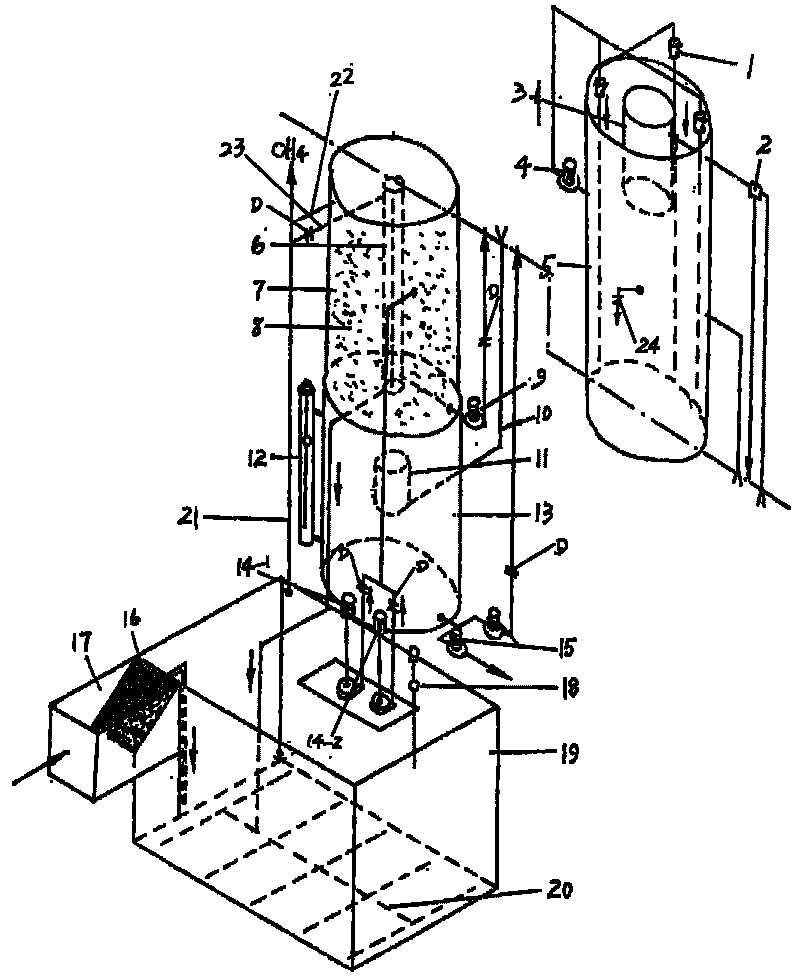

[0017] Such as figure 1 Shown, the composition of the miniature building block type reclaimed water treatment equipment of the present invention is as follows:

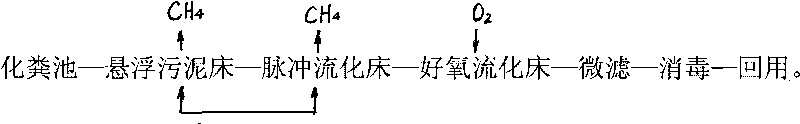

[0018] It is composed of a suspended sludge bed 19, a pulse fluidized bed 7, an aerobic fluidized bed 5, and a reclaimed water storage tank 13. The suspended sludge bed 19 has a sewage inlet, and a grid well 17 and a grid 16 are installed at the sewage inlet to remove There is a water distributor 20 in the suspended sludge bed for garbage and sediment, a biogas outlet pipe 21 and a liquid level controller 18 are installed on the top cover, and a lifting water pump 14-1, a circulating water pump 14-2, and a water pump Sewage is pumped out and sent to pulse fluidized bed 7. A pulse generator 6 is set in the pulse fluidized bed, and it is filled with a suspended biological filler 8 (commercially available), and a lifting pump 9 is provided at the bottom to pump water into the aerobic fluidized bed 5 installed above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com