Apparatus and process method for forcibly aging vehicle tail gas purification catalytic material

A technology of catalytic materials and process methods, which is applied in the field of devices for forced aging of catalytic materials for vehicle exhaust purification, and can solve problems such as lack of key parameter inspections or operating costs, affecting scientific research progress, and expensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

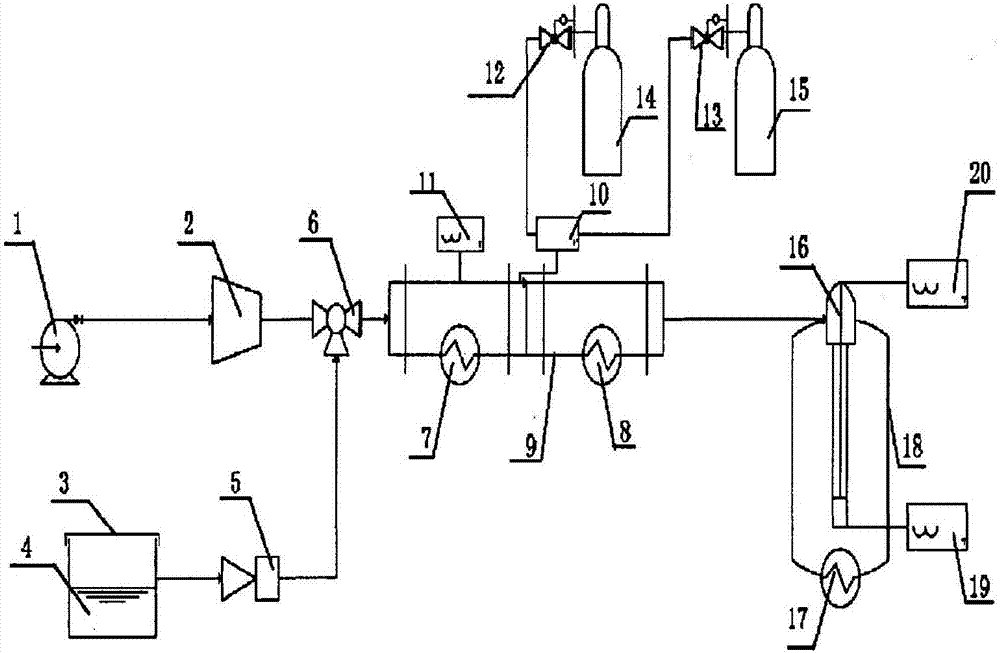

Image

Examples

Embodiment 1

[0038] The sample of Comparative Example 1 was subjected to hydrothermal forced aging treatment changing the air-fuel ratio, and the treatment space velocity was 10000h- 1 , from room temperature to 1050°C at a temperature of 10°C / min. After treatment time is 10 hours. The exhaust gas composition in the first 5 hours is hot nitrogen containing 10% water vapor, 5% hydrogen and 0% carbon dioxide by volume. The exhaust gas composition in the next 5 hours It is hot air containing 10% water vapor by volume. The catalytic material is still in the aging furnace during the cooling process, and the dry air is used as a protective atmosphere. Chemical and physical properties of materials and catalytic evaluation results.

[0039] Based on the series of aging treatments of the present invention, the basic physical properties of cerium-zirconium rare earth catalytic materials and the comparison of catalytic activities are disclosed.

[0040] Comparative example 1 corresponds to the physi...

Embodiment 6

[0047] The sample of comparative example 4 is subjected to Duramax engine bench aging treatment, and the processing space speed is 15000h- 1 , to simulate the 100000km operating load, and select 1 / 3, 2 / 3 and full-time operating nodes corresponding to 4, 8, and 12-hour aging for investigation. Chemical and physical properties of materials and catalytic evaluation results.

Embodiment 2

[0049] The comparative example 4 sample is subjected to hydrothermal forced aging treatment, and the processing space velocity is 15000h- 1 , the exhaust gas component is hot air containing 10% water vapor, 5% carbon dioxide and 0% hydrogen by volume, and the temperature is raised from room temperature to 800°C at 10°C / min for 4, 8, and 12 hours. The aging reaction tube was taken out and lowered to room temperature, during which dry air was used as a protective atmosphere. Chemical and physical properties of materials and catalytic evaluation results.

[0050] Phase composition analysis and comparison of catalytic activity of the barium-cerium-aluminum composite oxidation catalytic material based on the series of aging treatments of the present invention. Comparative example 4 corresponds to the physical and chemical properties of fresh barium-cerium-aluminum-based catalytic materials, and comparative examples 5 and 6 are the test results obtained from laboratory hydrothermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com