Degradable foam packaging material and its preparation method

A packaging material and foaming agent technology, which is applied in the field of degradable foaming packaging materials and their preparation, can solve the problems of no substitutes and achieve the effects of improving wear resistance, facilitating recycling, and reducing processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

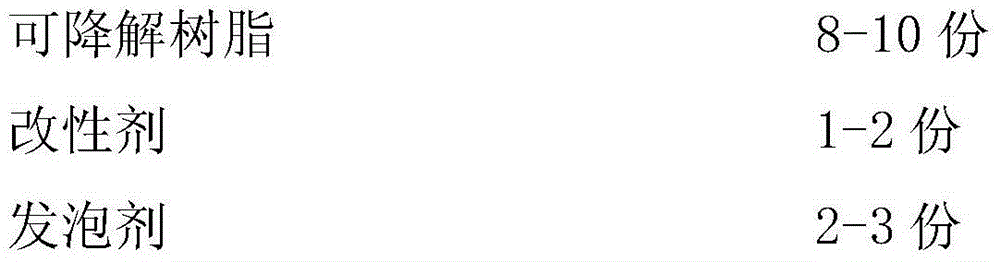

[0033] The degradable foaming packaging material comprises the following raw materials in parts by weight: 8 parts of degradable resin, 1.5 parts of modifier, 2.5 parts of foaming agent, 70 parts of plant fiber, and 5 parts of inorganic powder.

[0034] Table 1

[0035] name materials Parts by weight Degradable resin PLA 8 servings Modifier Terminal amino group 1.5 servings Foaming agent Sodium bicarbonate 2.5 servings plant fibres Rice Husk Powder 70 servings Inorganic powder talcum powder 5 servings

[0036] The preparation method of the degradable foam packaging material includes the following steps:

[0037] Step 1: Prepare raw materials according to the formula: degradable resin, modifier, foaming agent, plant fiber and inorganic powder;

[0038] Step 2: Put the plant fiber in an oven and dry it at a temperature of 50°C, and the drying time is 15 minutes;

[0039] Step 3: Ultrafine the dried plant fiber, then add inorganic powder, modifier, foaming agent and degradable res...

Embodiment 2

[0045] The degradable foaming packaging material contains the following raw materials in parts by weight: 9 parts of degradable resin, 2 parts of modifier, 3 parts of foaming agent, 75 parts of plant fiber, and 4.5 parts of inorganic powder.

[0046] Table 2

[0047] name materials Parts by weight Degradable resin PBAT, PBSA 9 servings Modifier Terminal amino group 2 servings Foaming agent Azoformamide 3 copies plant fibres Corn stalks 75 servings Inorganic powder talcum powder 4.5 servings

[0048] The preparation method of the degradable foam packaging material includes the following steps:

[0049] Step 1: Prepare raw materials according to the formula: degradable resin, modifier, foaming agent, plant fiber and inorganic powder;

[0050] Step 2: Put the plant fiber in an oven and dry it at a temperature of 80°C, and the drying time is 10 minutes;

[0051] Step 3: Ultrafine the dried plant fiber, then add inorganic powder, modifier, foaming agent and degradable resin for blen...

Embodiment 3

[0057] The degradable foaming packaging material comprises the following raw materials combined in parts by weight: 8 parts of degradable resin, 1 part of modifier, 2 parts of foaming agent, 70 parts of plant fiber, and 19 parts of inorganic powder.

[0058] table 3

[0059] name materials Parts by weight Degradable resin PLA, PBSA 10 servings Modifier Terminal amino group 1 serving Foaming agent Sodium bicarbonate 2 servings plant fibres Sawdust 80 servings Inorganic powder limestone 4 parts

[0060] The preparation method of the degradable foam packaging material includes the following steps:

[0061] Step 1: Prepare raw materials according to the formula: degradable resin, modifier, foaming agent, plant fiber and inorganic powder;

[0062] Step 2: Put the plant fiber in an oven and dry it at a temperature of 65°C, and the drying time is 12 minutes;

[0063] Step 3: Ultrafine the dried plant fiber, then add inorganic powder, modifier, foaming agent and degradable resin for b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com