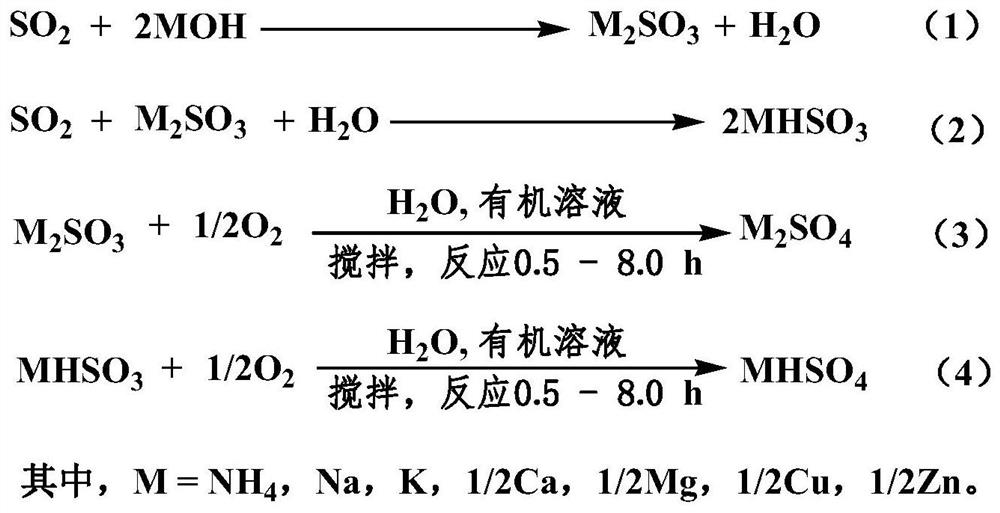

Oxidation method of sulfite or acidic sulfite or mixture thereof

A technology of acid sulfite and sulfite, applied in chemical instruments and methods, ammonia compounds, separation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

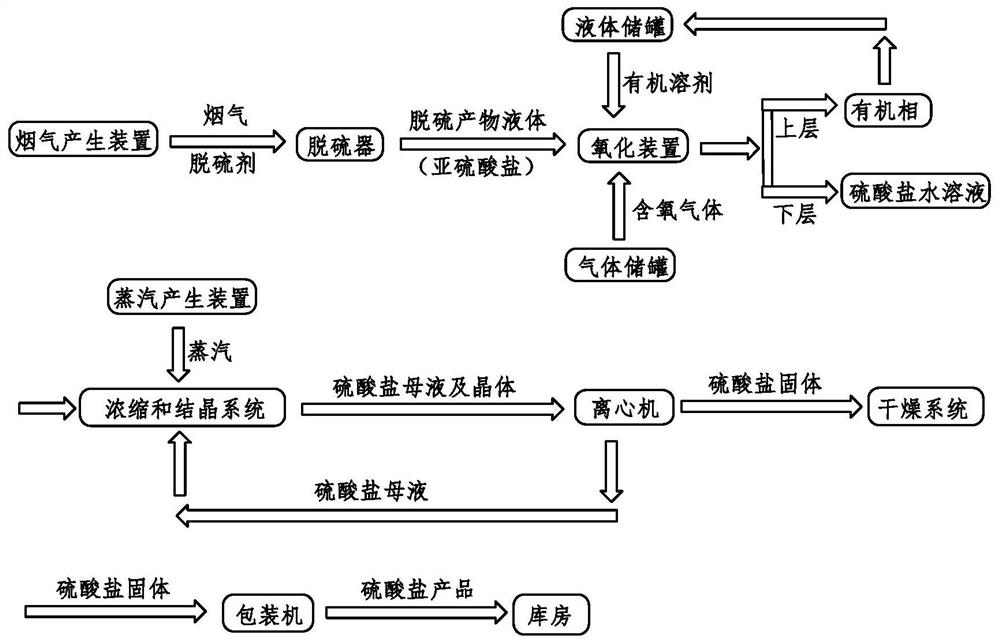

Method used

Image

Examples

Embodiment 1

[0071] A kind of oxidation method of sulfite, its concrete practice is:

[0072] A, preparation 2.0L molar concentration is the ammonium sulfite aqueous solution of 0.1mol / l, as water phase;

[0073] B. Add 0.8L of dodecane in the solution of step A as the organic phase;

[0074] C, pass into 20% oxygen in B step solution;

[0075] D. Control the pH of the step C solution at 6.0, the stirring speed is 500r / min, and react for 4.0h;

[0076] The upper solution in the heterogeneous solution of steps E and D is an organic solution containing dodecane, which is kept in the reactor and can be reused. The lower layer solution is an aqueous solution containing ammonium sulfate, which can be released from the bottom of the reaction kettle.

[0077] F. Under the condition that the pH is 6.0 and the temperature is 90° C., the ammonium sulfate aqueous solution in the E step is concentrated and crystallized. The crystals in saturated ammonium sulfate aqueous solution were separated by ...

Embodiment 2

[0080] A kind of oxidation method of sulfite, its concrete practice is:

[0081] A, preparation 2.0L molar concentration is the ammonium sulfite aqueous solution of 3.0mol / l, as water phase;

[0082] B. Add 2.0L of pentadecane in the solution of step A as the organic phase;

[0083] C, pass into 90% oxygen in B step solution;

[0084] D, the pH of the C step solution is controlled at 6.5, the stirring speed is 800r / min, and the reaction is 8.0h;

[0085] The upper solution in the heterogeneous solution of steps E and D is an organic solution containing pentadecane, which is kept in the reactor and can be reused. The lower layer solution is an aqueous solution containing ammonium sulfate, which can be released from the bottom of the reaction kettle.

[0086] F. Under the condition that the pH is 7.0 and the temperature is 70° C., the ammonium sulfate aqueous solution in the E step is concentrated and crystallized. The crystals in saturated ammonium sulfate aqueous solution ...

Embodiment 3

[0089] A kind of oxidation method of sulfite, its concrete practice is:

[0090] A, preparation 2.0L molar concentration is the ammonium sulfite aqueous solution of 4.0mol / l, as water phase;

[0091] B. Add 1.0L of dodecane and 1.0L of pentadecane to the solution in step A as the organic phase;

[0092] C, feed 100% oxygen in the B step solution;

[0093] D. Control the pH of the step C solution at 7.0, the stirring speed is 1200r / min, and the reaction is 8.0h;

[0094] The upper solution in the heterogeneous solution of E and D steps is an organic solution containing dodecane and pentadecane, which is kept in the reactor and can be reused. The lower layer solution is an aqueous solution containing ammonium sulfate, which can be released from the bottom of the reaction kettle.

[0095] F. Under the condition that the pH is 6.5 and the temperature is 75° C., the ammonium sulfate aqueous solution in the E step is concentrated and crystallized. The crystals in saturated ammon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com