Chimney white mud and mixed cotton fiber reinforced calcium silicate sheet

A technology of chimney white mud and calcium silicate board, which is applied in the field of building materials, can solve the problems of fiber weight, high cost, and complicated process, and achieve the effects of reducing production costs, reducing raw material costs, and increasing the number of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0024] Example blended cotton fibers glass fiber chimney plaster quartz Ordinary Portland Cement expanded perlite 1 7 2 17 46 25 1.6 2 6 1 20 46 .04 30 2 3 12 3 15 35 20 1 4 10 2 18 40 24 1 5 9 3 19 38 28 2

[0025] In the foregoing examples, the balance is water.

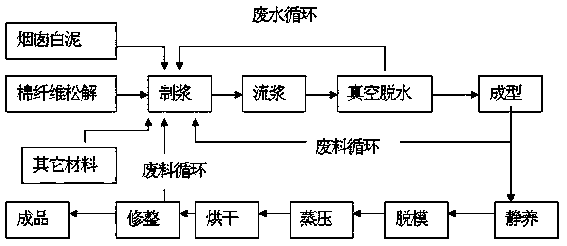

[0026] The production method of the above-mentioned embodiment is as follows: mix the above-mentioned raw materials with water, put them into a mixer and stir them evenly to form a mixed slurry, and then go through flow-flowing-vacuum dehydration-forming-resting and demolding-autoclaving reaction-drying-edging- finished product. The chimney lime mud mixed cotton fiber reinforced calcium silicate board of the present invention can be formed. During the vacuum dehydration of the slurry, the collected waste water is used for the next supplementary water circulation of the chimney lime mud mixed cotton and mixed slurry. The scraps from the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com