Sidewall panel for train carriage

A technology for side wall panels and compartments, applied in applications, home appliances, coatings, etc., can solve problems such as high pressure resistance, stiff feeling, and single color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

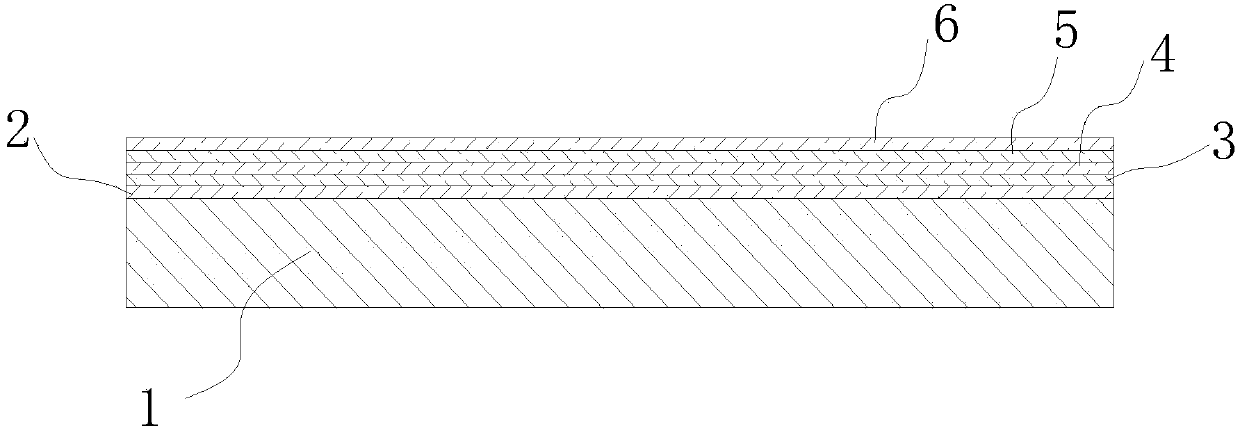

[0020] Embodiment one: see figure 1 As shown, the side wall panels for train carriages include an aluminum substrate 1, a primer 2 is coated on the aluminum substrate 1, a topcoat 3 is coated on the primer 2, and a topcoat 3 is coated on the topcoat 3. Varnish 6, the varnish 6 includes the following components in parts by weight: 58 parts of fluorine resin; 16 parts of acrylic resin; 9 parts of fluorine resin particles; 5 parts of isophorone or cyclohexanone; 4 parts of varnish additive; The varnish additive includes the following components in parts by weight: 1 part of leveling agent; 1 part of defoamer; 2 parts of dispersant; fluff powder is added in the varnish.

[0021] The primer 2 includes the following parts by weight: 36 parts of epoxy resin; 17 parts of acrylic resin; 30 parts of primer pigment; 3 parts of n-butyl acetate or ethyl acetate; 4 parts of cyclohexanone or isophorone 4 parts of primer additives; said primer additives include the following parts by weight:...

Embodiment 2

[0033] Embodiment 2: Embodiment 2 is basically the same as Embodiment 1, except that the varnish includes the following components in parts by weight: 55 parts of fluorine resin; 15 parts of acrylic resin; 8 parts of fluorine resin particles; 4 parts of ketone or cyclohexanone; 3 parts of varnish additive. The varnish additive includes the following components in parts by weight: 1 part of leveling agent; 1 part of defoamer; 1 part of dispersant.

[0034] The primer comprises the following components by weight: 35 parts of epoxy resin; 15 parts of acrylic resin; 29 parts of primer pigment; 3 parts of n-butyl acetate or ethyl acetate; 4 parts of cyclohexanone or isophorone; 3 parts of primer additive; the primer additive includes the following parts by weight: 1 part of leveling agent; 1 part of defoamer; 1 part of dispersant; the primer pigment includes the following parts by weight: antirust pigment 4 parts; 25 parts of titanium dioxide, those skilled in the art can select t...

Embodiment 3

[0036] Embodiment 3: Embodiment 3 is basically the same as Embodiment 1, except that the varnish includes the following components in parts by weight: 60 parts of fluorine resin; 20 parts of acrylic resin; 10 parts of fluorine resin particles; 6 parts of ketone or cyclohexanone; 6 parts of varnish additive. The varnish additive includes the following components in parts by weight: 2 parts of leveling agent; 2 parts of defoamer; 2 parts of dispersant.

[0037] The primer comprises the following components in parts by weight: 40 parts of epoxy resin; 20 parts of acrylic resin; 32 parts of primer pigment; 4 parts of n-butyl acetate or ethyl acetate; 5 parts of cyclohexanone or isophorone; Primer additive 6 parts. The primer additive includes the following parts by weight: 2 parts of leveling agent; 2 parts of defoamer; 2 parts of dispersant; the primer pigment includes the following parts by weight: 5 parts of antirust pigments; 27 parts of titanium dioxide Parts, those skilled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com