Method for manufacturing large-area nano gap electrode arrays in parallel

A nano-slit electrode and nano-slit technology, which is applied in the field of nano-manufacturing, can solve the problems of complex, time-consuming electrochemical processes, complex technological processes, etc., and achieve the effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

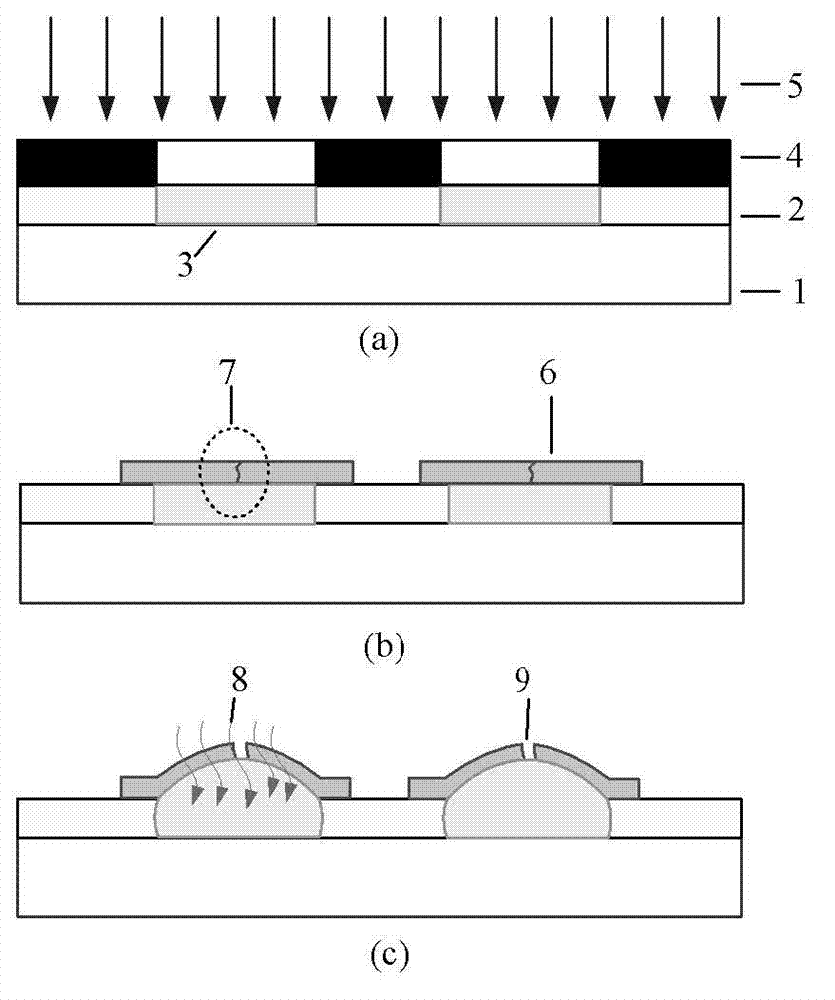

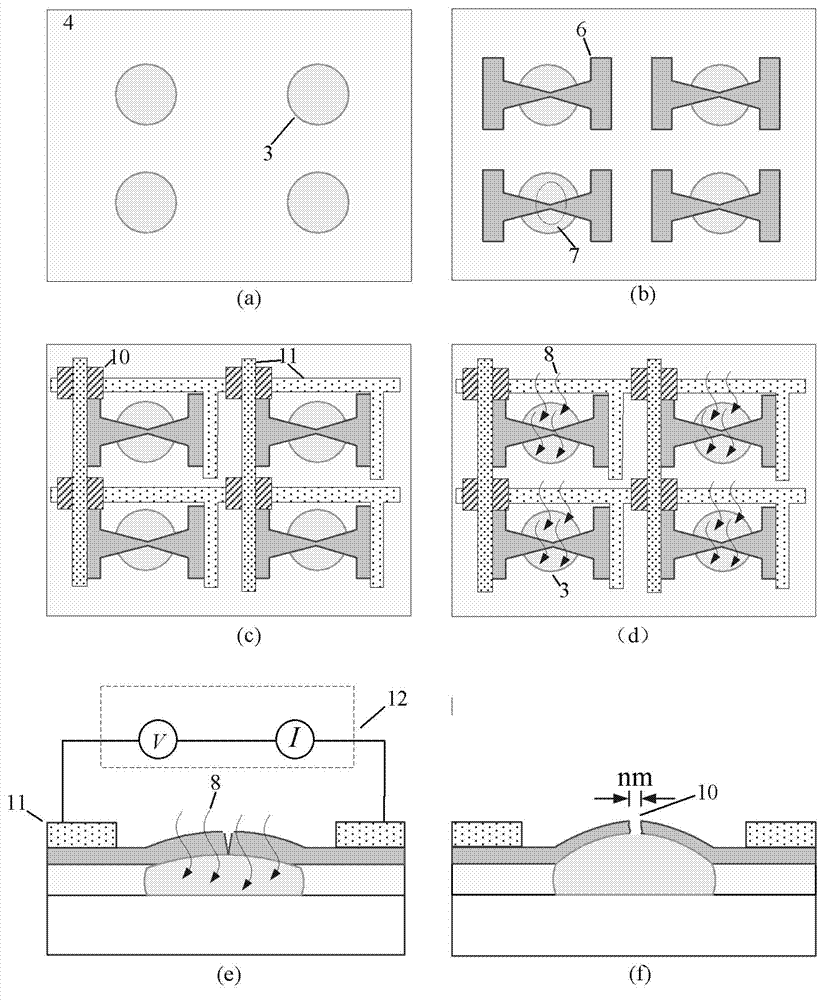

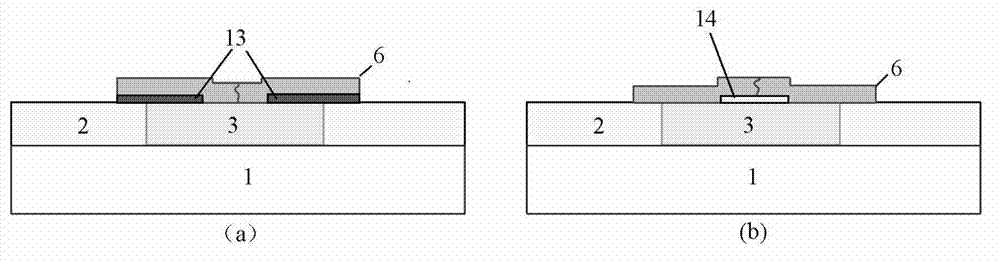

[0019] see figure 1 , a method for parallel fabrication of large-area nanoslit electrode arrays, first using energy beams 5 (ultraviolet light, electron beams, ion beams, and X-rays, etc.) Use the mask plate 4 to carry out beam exposure, after the exposure, PMMA long-bond molecules become short-bond molecules, see figure 1 (a); Then, prepare the metal electrode film 6 on the PMMA photoresist surface, and preset the stress concentration opening 7 at the position where nanoslits need to be produced, for producing stress concentration in the film stretching process, which is easier to generate at the designated position nanoslit, see figure 1 (b); Finally, the short-bond PMMA molecule after exposure absorbs MMA monomer molecule 8 and expands, applying force to the metal film on the upper layer, and the film breaks to produce nano-slit structure 9, see figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com