Heavily-doped blast furnace slag cement and preparation method thereof

A technology of blast furnace slag and high dosage, applied in cement production, clinker production and other directions, can solve the problems of increased efficiency, high cost of consumables, and cumbersome production process, and achieves the effect of increasing dosage and saving dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

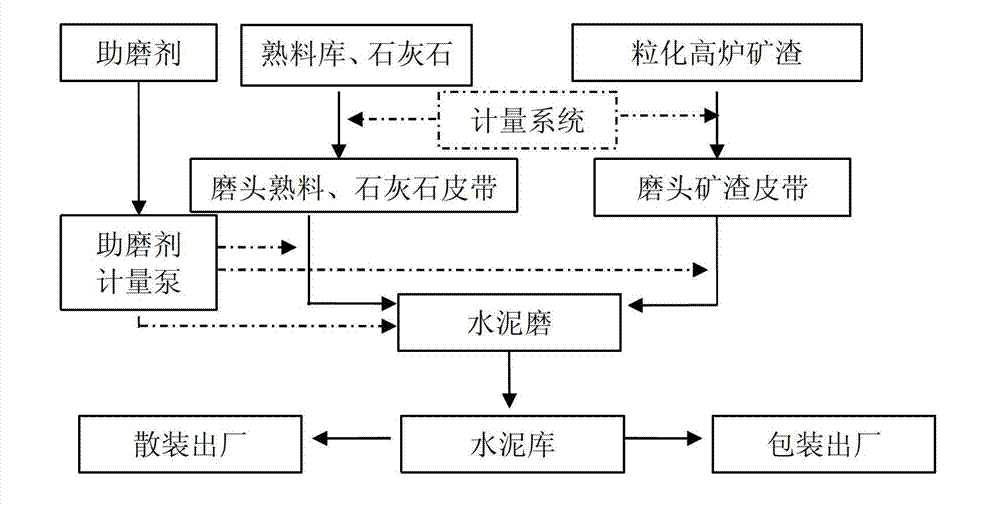

Method used

Image

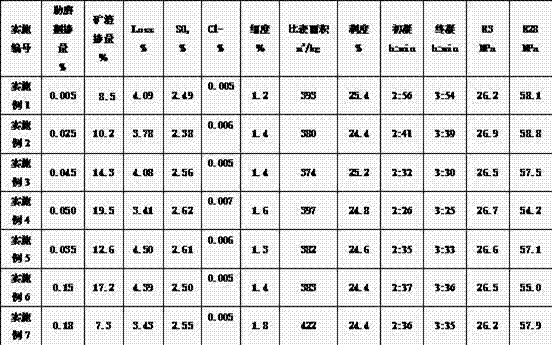

Examples

Embodiment 1

[0040] (1) Batching storage: cement clinker, granulated blast furnace slag, and limestone are sent to the batching storage by the conveying system.

[0041] (2) Batching and grinding processing: cement clinker, granulated blast furnace slag, and limestone in the batching warehouse pass through the metering system, and the batching is measured according to the mass ratio of 85:9:6, and then the cement clinker, limestone, The slag belt sends the measured ingredients into the cement mill, starts the cement mill for grinding, the stirring speed is 1200rmp, and the stirring time is 4h.

[0042] (3) Grinding aid dripping: While the cement mill is grinding cement clinker, granulated blast furnace slag, and limestone, the dripping amount of the grinding aid propylene glycol is controlled at 0.025% by a metering pump, and the grinding aid is measured The flow rate controlled by the pump is 120~150L / h, and the grinding aid is evenly dropped into the cement mill from the clinker belt...

Embodiment 2

[0045] (1) Batching storage: cement clinker, granulated blast furnace slag, and limestone are sent to the batching storage by the conveying system.

[0046] (2) Batching and grinding: the cement clinker, granulated blast furnace slag, and limestone in the batching warehouse pass through the metering system, and the batching is measured according to the mass ratio of 78:15:7, and then the cement clinker, limestone, The slag belt sends the measured ingredients into the cement mill, starts the cement mill for grinding, the stirring speed is 1000rmp, and the stirring time is 2.5h.

[0047] (3) Dropping of grinding aids: While the cement mill is grinding cement clinker, granulated blast furnace slag, and limestone, the mixed dropping amount of grinding aids triethanolamine and ammonium acetate is controlled at 0.065% by a metering pump , the flow rate controlled by the grinding aid metering pump is 120~150L / h, the grinding aid is evenly added dropwise from the mixing point to t...

Embodiment 3

[0050] (1) Batching storage: cement clinker, granulated blast furnace slag, and limestone are sent to the batching storage by the conveying system.

[0051] (2) Batching and grinding: the cement clinker, granulated blast furnace slag, and limestone in the batching warehouse pass through the metering system, and the batching is measured according to the mass ratio of 82:12:6, and then the cement clinker, limestone, The slag belt sends the measured ingredients into the cement mill, starts the cement mill for grinding, the stirring speed is 1500rmp, and the stirring time is 3.5h.

[0052] (3) Dropping of grinding aids: While the cement mill is grinding cement clinker, granulated blast furnace slag, and limestone, the mixed dropping amount of grinding aids ammonium acetate and capric acid is controlled at 0.085% by metering pumps , the flow rate controlled by the grinding aid metering pump is 150~160L / h, the grinding aid is evenly added dropwise from the slag belt of the grind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com