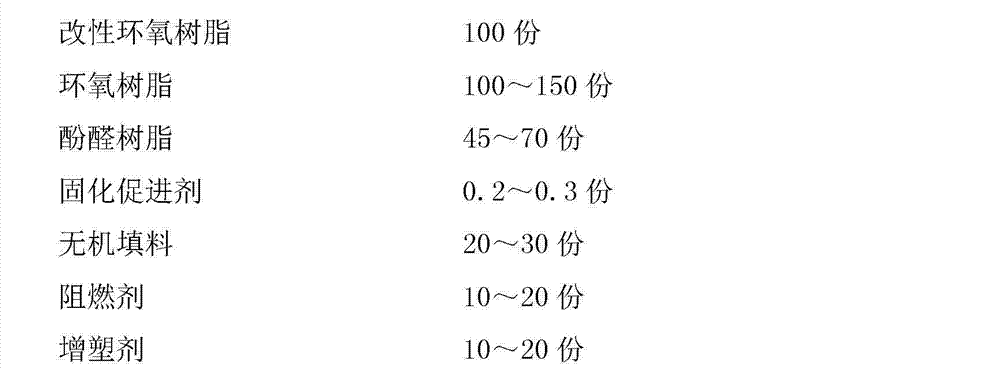

Preparation method of modified epoxy resin/flame-retardant glass cloth paper composite-base copper clad plate

An epoxy resin and modification technology, which is applied in the direction of chemical instruments and methods, glass/slag layered products, layered products, etc., can solve the problem of high water absorption, water absorption performance, and electrical performance of CEM-1 plates. Environmental protection difficulty and hazards and other issues, to achieve the effect of green production process, low water absorption, good flame retardant and self-extinguishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

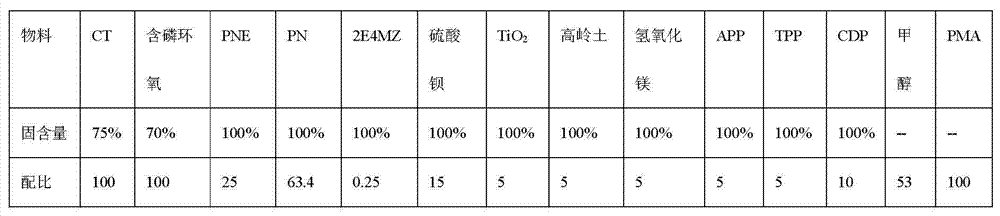

Examples

Embodiment 1

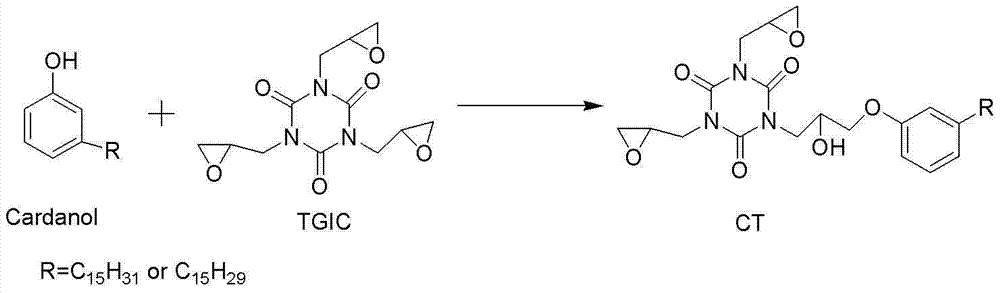

[0037] A kind of preparation method of novel flexible epoxy resin, its step comprises:

[0038]Add cardanol: TGIC: lithium hydroxide (50% aqueous solution) into the reactor at a mass ratio of 100:100:0.2, control the reaction temperature at 120°C, heat and stir for 10 hours, test the epoxy value to the end of the reaction, and end the reaction. Cool to room temperature and add 86 parts of propylene glycol monomethyl ether to obtain a relatively low molecular weight flexible epoxy resin (CT) with a solid content of 75%.

Embodiment 2

[0040] A kind of preparation method of novel flexible epoxy resin, its step comprises:

[0041] Add cardanol: TGIC: dimethylimidazole into the reactor at a mass ratio of 100:100: 0.1, control the reaction temperature at 160°C, heat and stir for 2 hours, test the epoxy value to the end of the reaction, end the reaction, cool to room temperature and add 86 parts of butanone obtained a relatively low molecular weight flexible epoxy resin (CT) with a solid content of 75%.

Embodiment 3

[0043] A kind of preparation method of novel flexible epoxy resin, its step comprises:

[0044] Add cardanol: TGIC: dimethylimidazole into the reactor at a mass ratio of 100:100:0.15, control the reaction temperature at 140°C, keep warm and stir for 6 hours, test the epoxy value to the end of the reaction, finish the reaction, cool to room temperature and add 43 parts of propylene glycol monomethyl ether and 43 parts of methyl ethyl ketone were used to obtain a relatively low molecular weight flexible epoxy resin (CT) with a solid content of 75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com