Cotton type chinlon short fiber and cotton blending and spinning process

A cotton blended and nylon technology, applied in the field of spinning, can solve the problems of difficulty in producing and processing blended yarns, high mass specific resistance, electrostatic entanglement, etc., to ensure wear resistance and dimensional stability, meet application requirements, improve Hygroscopic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Cotton-type nylon staple fiber is selected from domestic single 6 cotton-type nylon staple fiber, with a fineness of 1.67dtex and a length of 38mm.

[0017] The cotton laps that have been cleaned are made of high-quality cotton, with an average grade of 2.41, a main body length of 29.2mm, a quality length of 33.66mm, a tex number of 1.73dtex, a maturity coefficient of 1.59, and a short staple (below 16mm) of 12.20%. The uniformity is 1170, the moisture regain is 8.8%, and the impurity content is 1.0%.

[0018] A cotton-type nylon staple fiber and cotton blended spinning process, the process flow is as follows:

[0019] Pretreated nylon staple fiber + cotton laps that have been cleaned → artificial cotton pile mixed → cleaning A002D → A035 → A036C → A092 → A076C → carding (A186 or FA231A) → drawing (FA305C) (three passes) → Roving (A454E) → Spun Yarn (A507A) → Winding (Lorian)

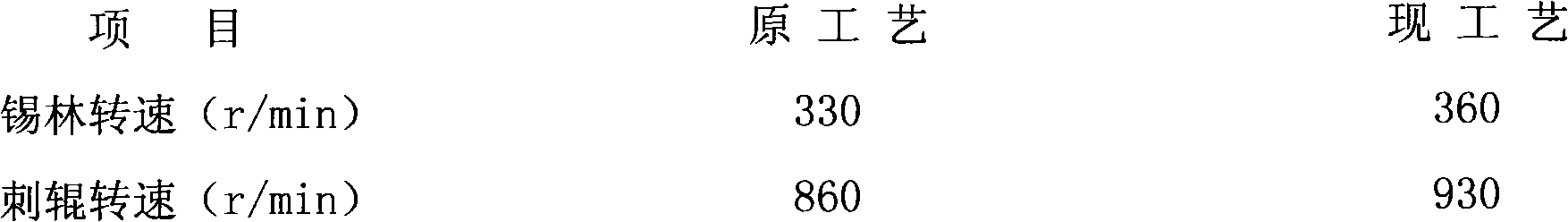

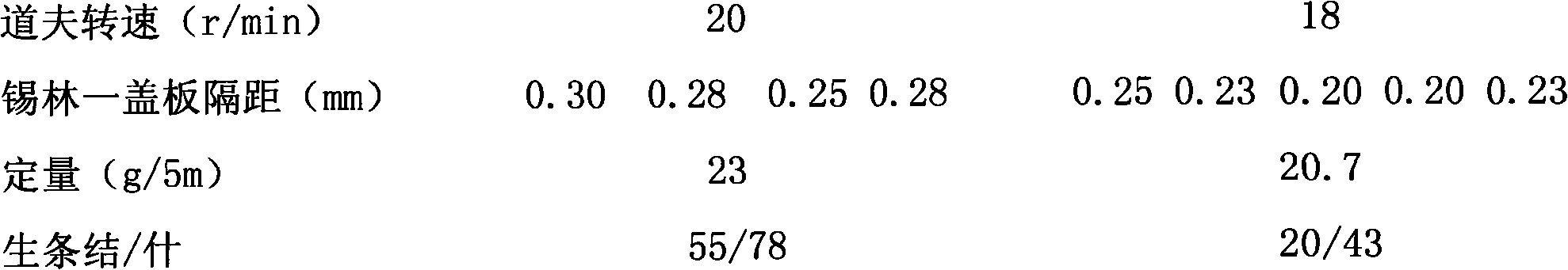

[0020] The main process parameters and technical measures of each process:

[0021] 1. Cot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com