Fan linkage pitch system

A fan and linkage technology, applied in the control of wind turbines, machines/engines, wind turbines, etc., can solve the problems of heavier weight of the nose part, complicated control system, and increased moment of inertia of the impeller, so as to extend the operating life and ensure The effect of operating safety and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

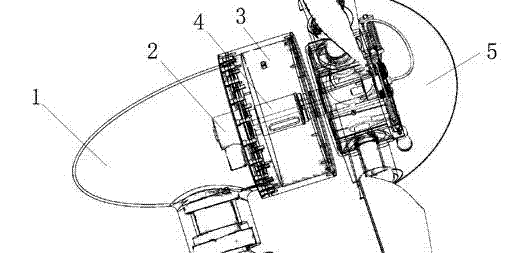

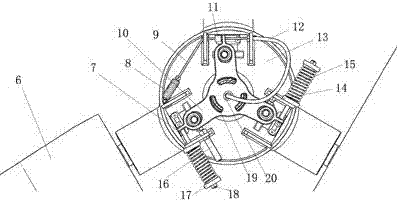

[0038] Such as figure 1 It is shown in the overall schematic diagram of the present invention applied to a wind power generating set. A fan is composed of a cabin 1, an electric stretching system 2, a generating set 3, a hollow generator main shaft 4 and a shroud 5. Such as Figures 2 to 6 As shown, a wind turbine linkage pitch change system is used for manual and electric linkage pitch change of fans, including a blade set and a pitch change system connected to the nose hub 13, and the pitch change system includes manual pitch change and electric pitch change pulp, of which,

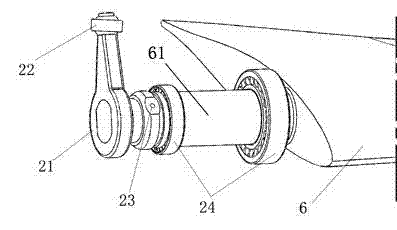

[0039] The blade group is composed of more than two blades 6 with blade root shafts 61 installed on the nose wheel hub 13 through blade shaft bearings 24), the centerlines of each blade root shafts intersect at the center line of the nose wheel hub, and the blade root shafts 61 The root part is connected with the gravity rod 21 through the profile, and each gravity rod 21 is connected with the linkage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com