An interval-based method for predicting the performance of CNC machine tools

A technology of numerical control machine tools and prediction methods, applied in program control, computer control, general control systems, etc., to achieve strong prediction robustness, improved prediction accuracy, and good robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The following embodiments are only exemplary and do not constitute a limitation to the present invention.

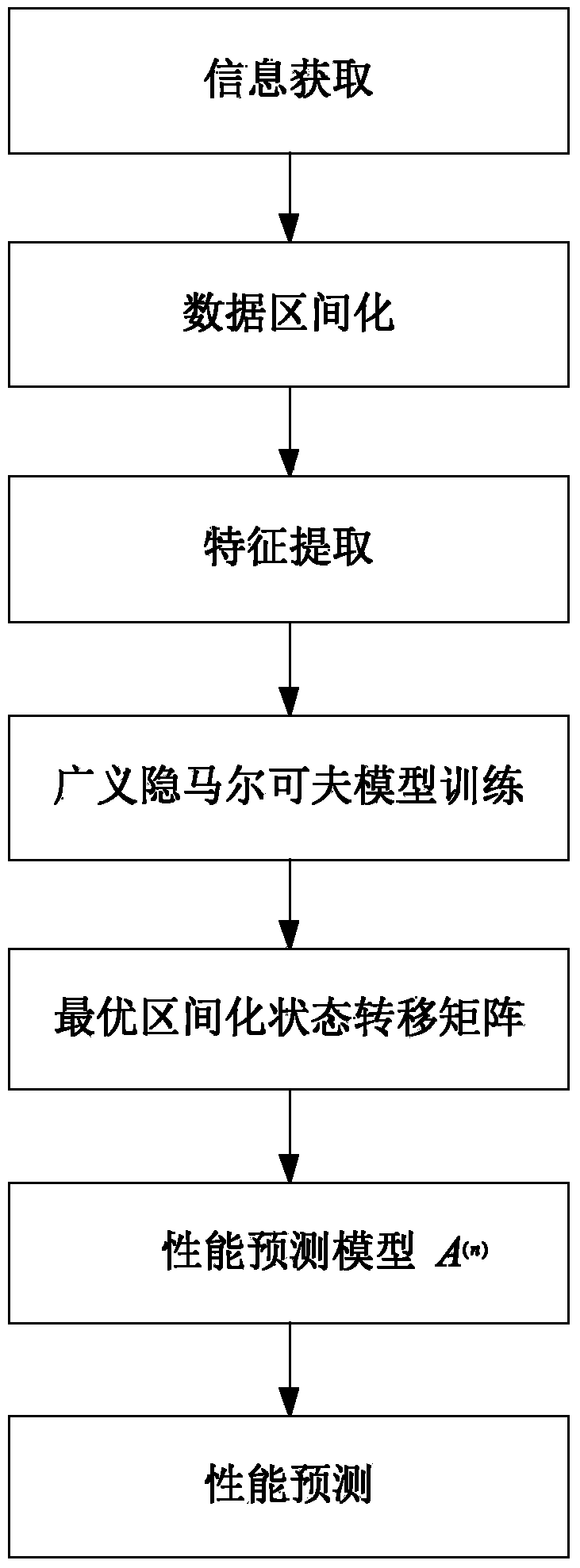

[0035] The definition of dynamic stiffness is the mechanical impedance when the response is displacement. It is a characteristic to measure the structure’s ability to resist predetermined dynamic disturbances, and it is also an important part of the performance of CNC machine tools. The present invention predicts the performance of CNC machine tools through intervalized dynamic stiffness for implementation. For further illustration, see the attached figure 1 .

[0036] A method for predicting the performance of a numerically controlled machine tool based on an interval in this embodiment specifically includes the following steps:

[0037] (1) Information acquisition

[0038] Obtain measurement data in CNC machine tool processing through m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com