Environmental-friendly automobile air conditioner and interior environment purification agent and preparation method thereof

A technology for automobile air conditioners and purifiers, which is applied in the fields of botanical equipment and methods, plant growth regulators, biocides, etc., can solve the problems of damage to the evaporation box or other components, shortening the service life, and affecting the health of drivers and passengers. Achieve good product quality, improve efficiency, and achieve excellent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

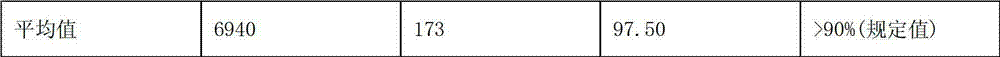

Examples

Embodiment 1

[0025] 1) Add 10 kg of tobacco stems, 4 kg of wormwood, 2 kg of pine leaves, 1 kg of Artemisia annua, 1 kg of job's tears, 2 kg of camphor leaves, 50 g of catalyst and 50 L of deionized water into a 100L reactor. Tight, check the airtightness to make it airtight.

[0026] 2) Turn on the ventilation switch, let in 60psi air, and turn off the switch.

[0027] 3) Put the reaction kettle on the electric heating mantle, set the temperature at 90 degrees, and use the sensor to control the temperature.

[0028] 4) After reacting for 8 hours, stop heating and cool the reaction kettle to room temperature.

[0029] 5) When the reaction kettle is completely cooled and the pressure does not change any more, release excess gas, filter the reaction solution, and reuse the filter residue once. After the filtrate is tested, adding 0.1-1.2% stabilizer to the total weight of the filtrate is the finished product.

[0030] 6) Put the cleaning agent obtained in this embodiment on the designated...

Embodiment 2

[0034] 1) Add 11 kg of tobacco stems, 5 kg of wormwood, 1 kg of pine leaves, 2 kg of Artemisia annua, 0.5 kg of job's tears, 4 kg of camphor leaves, 100 g of catalyst and 50 L of deionized water into the 100L reactor. Tight, check the airtightness to make it airtight.

[0035] 2) Turn on the ventilation switch, let in 90psi air, and turn off the switch.

[0036] 3) Put the reaction kettle on the electric heating mantle, set the temperature to 100 degrees, and use the sensor to control the temperature.

[0037] 4) After reacting for 6 hours, stop heating and cool the reaction kettle to room temperature.

[0038] 5) When the reaction kettle is completely cooled and the pressure does not change any more, release excess gas, filter the reaction solution, and reuse the filter residue once. After the filtrate is tested, adding 0.1-1.2% stabilizer to the total weight of the filtrate is the finished product.

[0039] 6) The extinction rate of natural bacteria is 96%.

Embodiment 3

[0041] 1) Add 6kg of tobacco stems, 10kg of wormwood, 3kg of pine leaves, 1kg of Artemisia annua, 3kg of camphor leaves, 80g of catalyst and 50L of deionized water into a 100L reactor, tighten the reactor, and check the gas Tightness, so that it does not leak.

[0042] 2) Turn on the ventilation switch, let in 60psi air, and turn off the switch.

[0043] 3) Put the reaction kettle on the electric heating mantle, set the temperature to 80 degrees, and use the sensor to control the temperature.

[0044] 4) After reacting for 9 hours, stop heating and cool the reaction kettle to room temperature.

[0045] 5) When the reaction kettle is completely cooled and the pressure does not change any more, release excess gas, filter the reaction solution, and reuse the filter residue once. After the filtrate is tested, adding a stabilizer accounting for 0.1-1.2% of the total weight of the filtrate is the finished product.

[0046] 6) The extinction rate of natural bacteria is 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com