Stainless steel water faucet sand-coating casting process

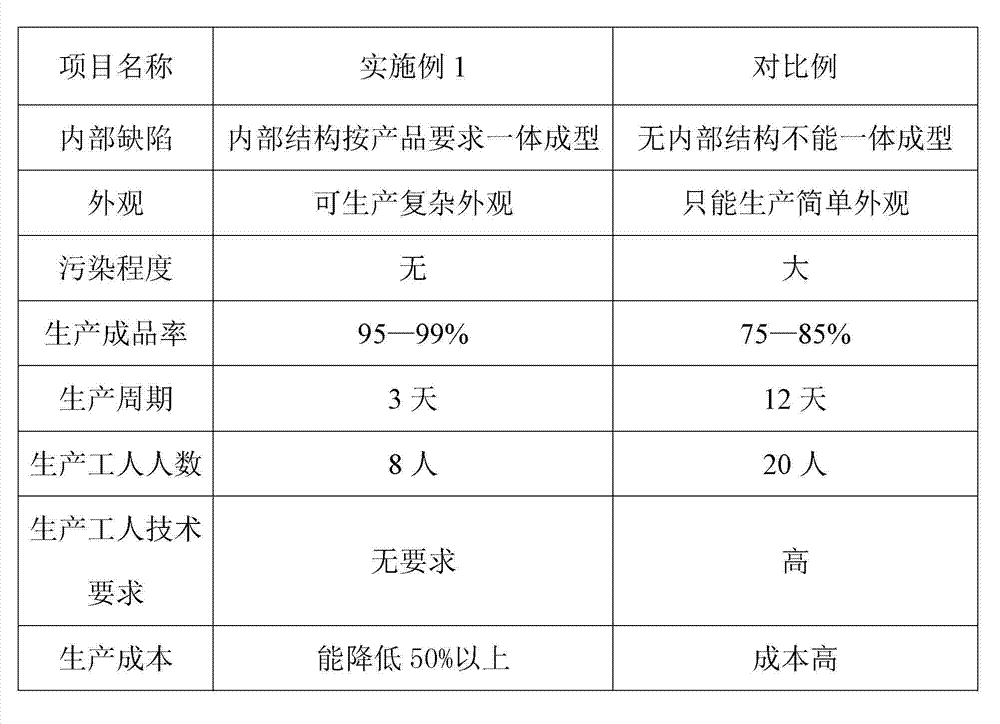

A casting process and technology of coated sand, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of shortened delivery cycle, long delivery cycle and high cost, and achieve high product yield and short production cycle. , the effect of size standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A coated sand casting process for a stainless steel faucet, which consists of the following steps in sequence,

[0026] A. Simulation of casting casting and cooling and solidification process: the mold temperature field test and simulation of the casting and solidification process are carried out by computer, and the thermal physical parameters of the mold are tested and measured;

[0027] B. Make the 3D drawing of the product: According to the product requirements, use Pro / E or UG 3D design software to make the 3D drawing of the product according to the simulation process, adopt the bottom casting casting design, that is, the casting port is set at the bottom of the product, so that the sand inside the product The gas produced after the core is heated slowly blows out, thereby improving the yield of the product; in this embodiment, Pro / E three-dimensional design software is used;

[0028] C. Prepare the mold: prepare the inner core mold and outer shell mold according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com