Method for brazing diamond drilling tools

A technology of diamond drilling and brazing method, applied in welding equipment, metal processing equipment, manufacturing tools and other directions, can solve the problems of affecting the use effect of the tool, affecting the life of the tool, increasing the processing difficulty, etc., to improve the usable range and welding heating time. The effect of short, short welding cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

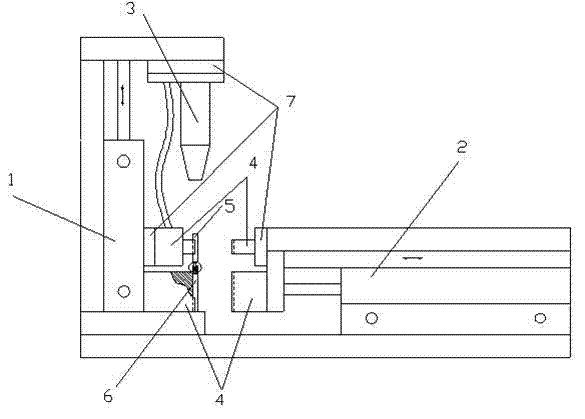

Image

Examples

Embodiment 1

[0023] Put solder between the diamond drill rod and the diamond, the composition and weight percentage of the solder are: Ag60%, Cu35%, Ti1.5%, Si3.5%, assemble the cutter rod and electrode on the brazing device, and pass Direct current heating until the solder melts, and after the solder melts, the diamond is quickly pressed toward the drill rod, so that the diamond partially touches the drill rod, and the tool is cooled slowly after heating.

Embodiment 2

[0025] Put solder between the diamond drill rod and the diamond, the composition and weight percentage of the solder are: Ag71%, Cu23.5%, Ti0.5%, Si5%, assemble the cutter rod and electrode on the brazing device, and pass Heating with alternating current until the solder melts, and after the solder melts, the diamond is quickly pressed toward the drill rod, so that the diamond partially touches the drill rod, and the tool is cooled slowly after heating.

Embodiment 3

[0027] Place solder between the diamond drill rod and the diamond. The composition and weight percentage of the solder are: Ag71%, Cu20%, Ti1%, Si8%, and the cutter rod and electrode are assembled on the brazing device. Heating until the solder melts, and after the solder melts, quickly pressurize the diamond toward the drill rod, so that the diamond partially touches the drill rod, and the tool is cooled slowly after heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com