Method for preparing active carbon for relieving or neutralizing effect of alcohol

A technology of activated carbon and carbonization, used in chemical instruments and methods, antidote, inorganic chemistry, etc., to achieve the effect of food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of preparation method of the gac used for hangover of the present invention, comprises the following steps:

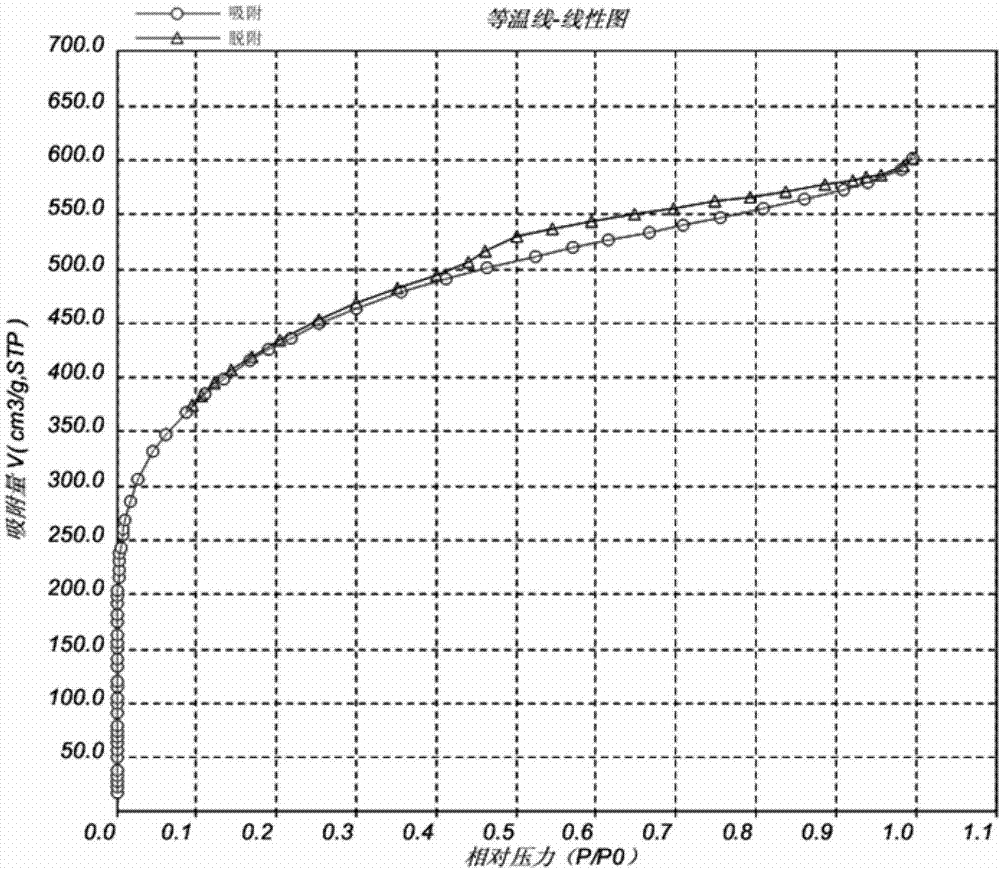

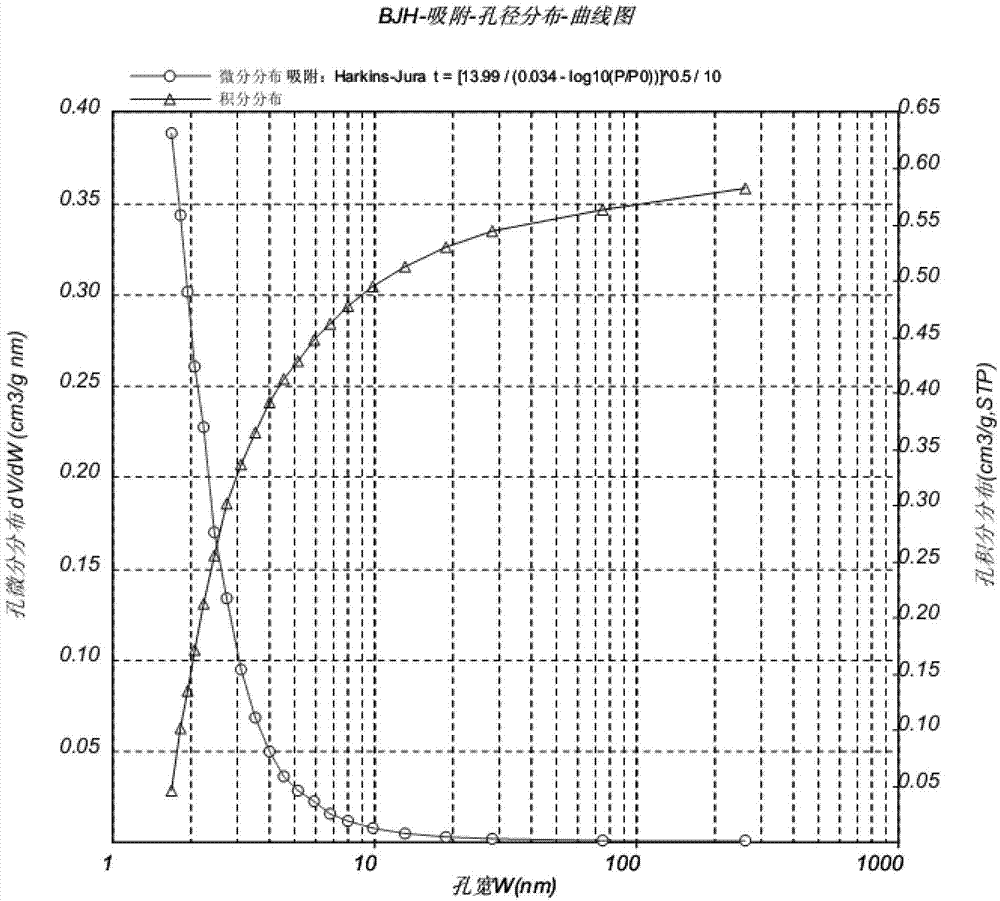

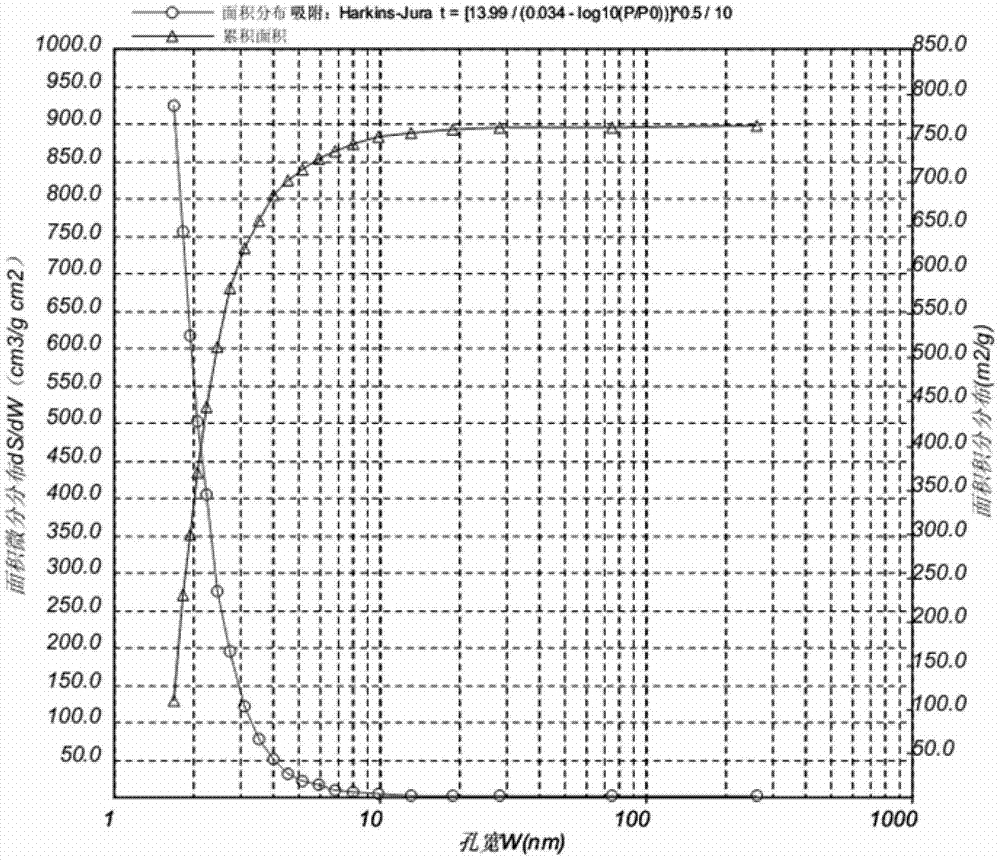

[0032] Step A: using moso bamboo that is more than 4 years old, taking the hard part in the middle as raw material; carbonizing the above raw material in an externally heated carbonization furnace at a temperature of 600°C to 900°C, carbonizing for 10 to 20 hours, and crushing after carbonization; The carbonized material is activated by heating and feeding high-temperature steam. The carbonized material rolls slowly forward in the activation chamber. The raw material after carbonization is activated, the activation temperature is 850°C-900°C, and the activation time is 4 hours. Customized activated carbon with a certain pore size distribution and specific surface area; the customized activated carbon has a pore volume of 0.35 to 0.6 cm with a pore size below 1.0 nanometers 3 / g, the pore volume between 1.0 nanometers and 25 nanometers is 0.45~0.60cm 3 / ...

Embodiment 2

[0037] A kind of preparation method of the gac used for hangover of the present invention, comprises the following steps:

[0038] Step A: Use northeast red pine wood as raw material; carbonize the above-mentioned raw material at a temperature of 500°C to 600°C for 5 hours, and then crush it after carbonization; activate the carbonized material by indirect external heating and introducing high-temperature steam, and the carbonized material is in the The activation chamber slowly rolls forward, and the direction of the high-temperature water vapor is the same as that of the carbonized material, so that the high-temperature water vapor and the carbonized material are fully contacted for activation. The activation temperature is 860 ° C ~ 930 ° C, and the activation time is 6 hours. Customized activated carbon with a certain pore size distribution and specific surface area; the pore volume of the customized activated carbon with a pore size below 1.0 nm is 0.35-0.60 cm 3 / g, the po...

Embodiment 3

[0043] A kind of preparation method of the gac used for hangover of the present invention, comprises the following steps:

[0044] Step A: using moso bamboo more than 4 years old, and taking the hard part in the middle as raw material;

[0045] The above raw materials are carbonized in an externally heated carbonization furnace at a temperature of 700°C for 10 to 25 hours, and then crushed after carbonization; the carbonized materials are activated by indirect external heating and high-temperature steam, and the carbonized materials are slowly heated in the activation chamber. Rolling forward, the direction of introducing high-temperature water vapor is the same as that of the carbonized material. The high-temperature water vapor makes full contact with the carbonized material for activation. The activation temperature is 850 ° C to 900 ° C, and the activation time is 5 hours. Customized activated carbon with a certain pore size distribution and specific surface area; the pore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com