Expanded perlite ore preheating furnace and working method thereof

A technology of expanded perlite and preheating furnace, which is applied in expanded perlite ore preheating furnace and its working field, which can solve the problems of uncontrollable preheating temperature and preheating time, failure of heat exchanger to work normally, and decrease of heat exchange efficiency To achieve the effect of improving energy utilization, avoiding gas leakage and reducing warm-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

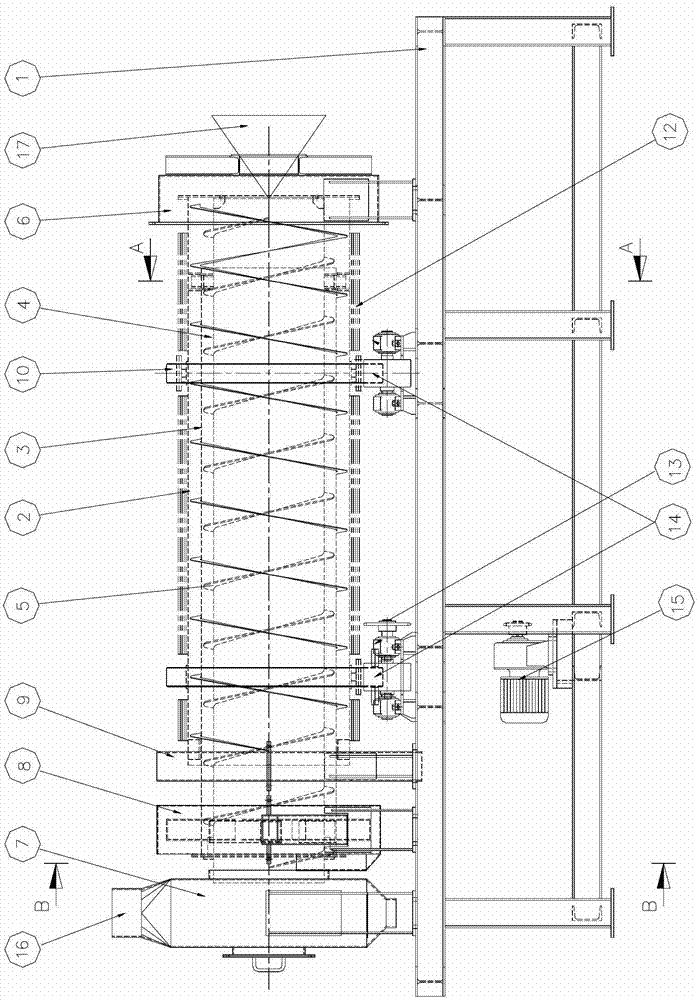

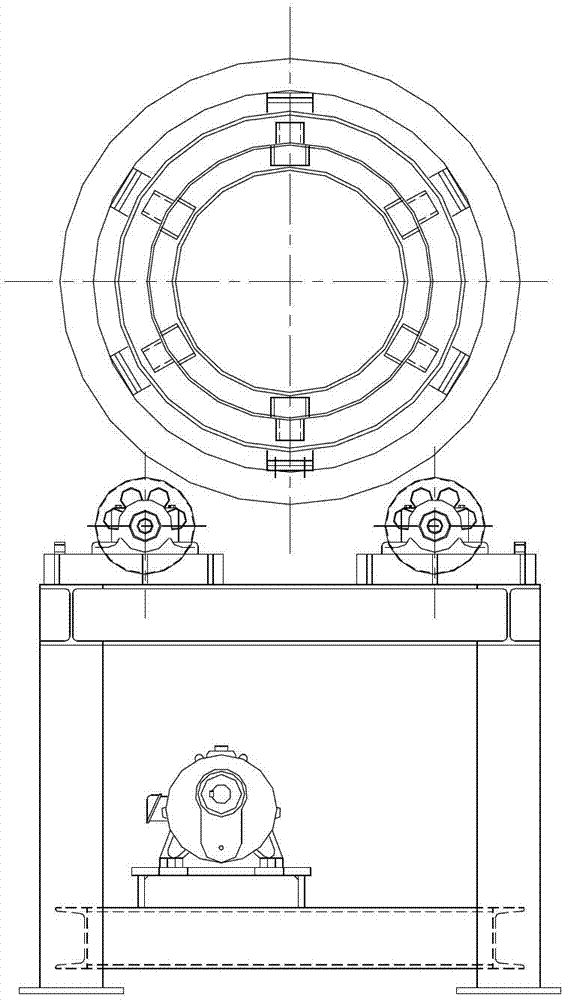

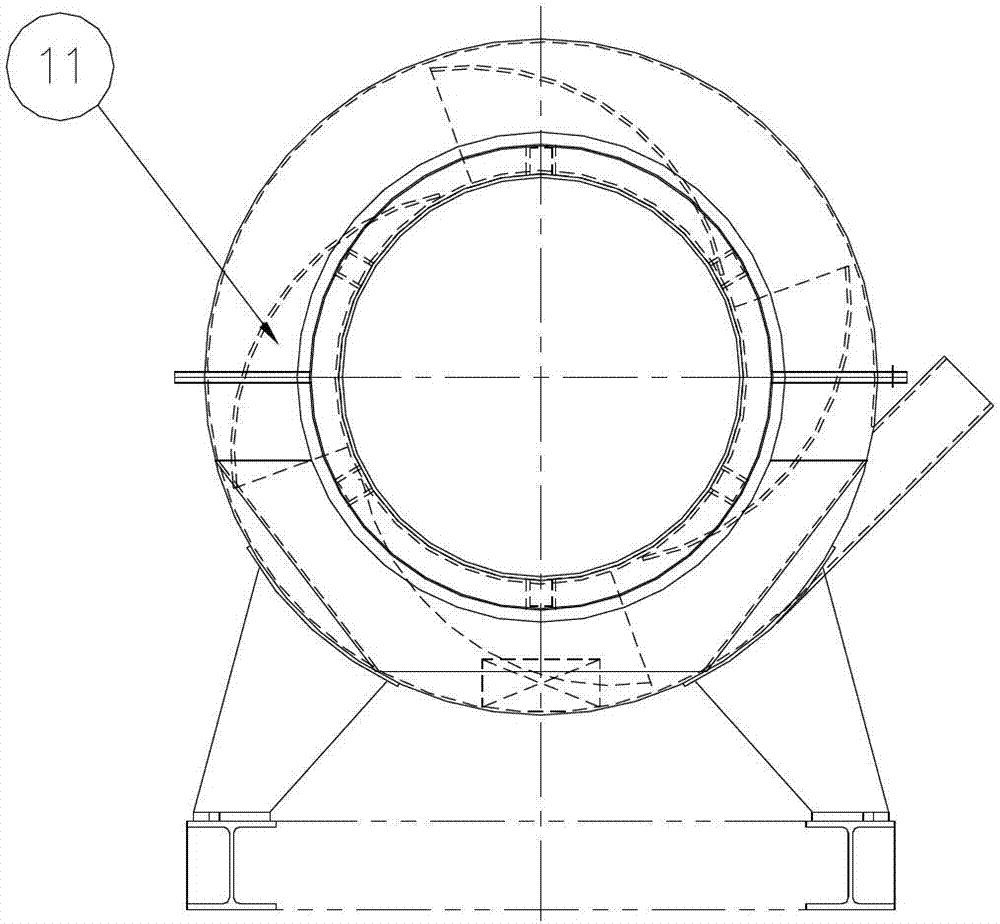

[0041] Embodiment: a kind of expanded perlite ore preheating furnace (see figure 1 , figure 2 , image 3 ), which is characterized in that it includes a feeding device, a preheating device, a support structure, a combustion device and an air induction device; wherein the feeding device includes a feeding port 9 and a spoon 11; the preheating device includes a spiral plate 5, an inner cylinder 4, and a middle cylinder 3 and the outer cylinder 2; the supporting structure includes a driving wheel 13, a supporting wheel 14 and a driving motor 15; the combustion device includes a front cover 6 and a burner 17; the air induction device includes a rear cover 7, an external induced draft fan and a pipeline 16; The inner cylinder 4 and the middle cylinder 3 form an inner heating chamber, the middle cylinder 3 and the outer cylinder 2 form an outer heating chamber, the outlet of the inner heating chamber is connected with the inlet of the outer heating chamber, and the outlet of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com