Low-fluorescent-oil-based lubricant for drilling fluid based on reclaimed oil and derivatives thereof

An oil-based lubricant, a technology for regenerating grease, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of large adsorption consumption, low lubricant dispersion, fast lubricant consumption, etc., and achieve biodegradability. Good, good dispersion, resource saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

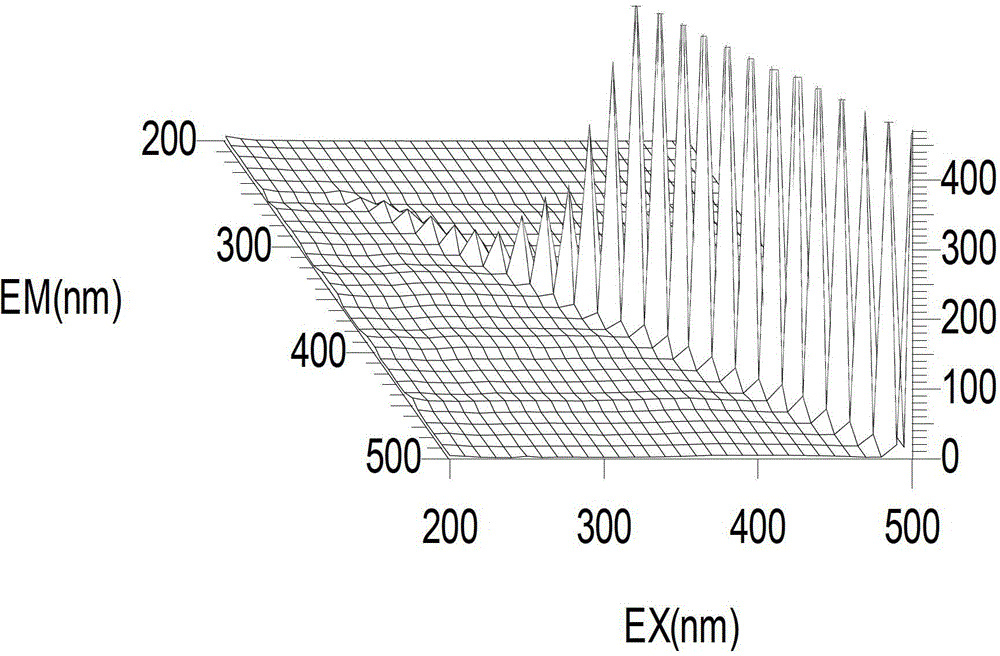

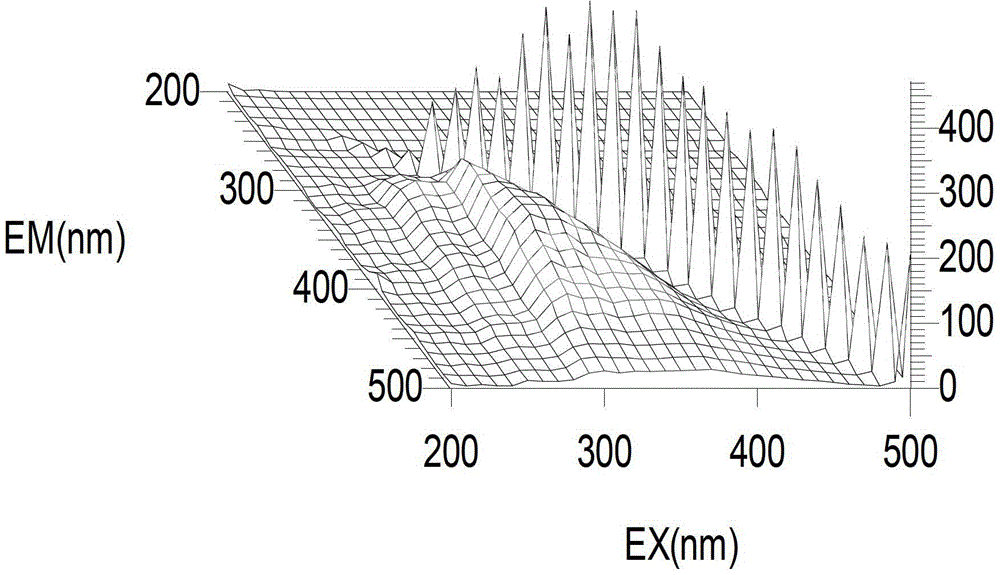

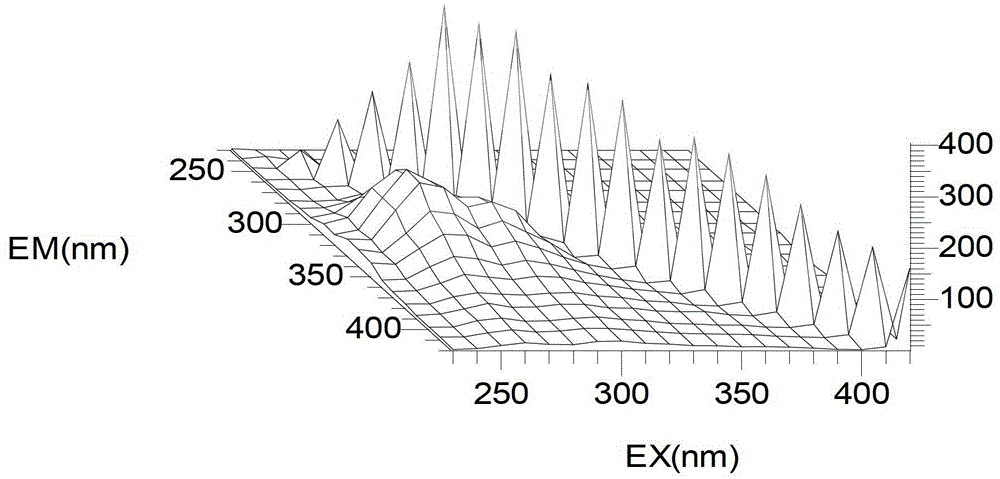

Image

Examples

Embodiment 1

[0044] Example 1 Preparation of Low Fluorescence Oil-based Lubricant for Drilling Fluid Based on Regenerated Grease and Its Derivatives

[0045] Mix 100g of waste oil, 5g of concentrated sulfuric acid and 7g of triethanolamine to carry out esterification reaction, the reaction temperature is controlled at 140°C, and the reaction time is 4h;

[0046] Add 100g of refined fatty acid methyl ester and 20g of solid nitric acid to the reactants obtained above, and react at a temperature of 100°C for 1h to obtain a low-fluorescence oil-based lubricant for drilling fluid based on regenerated oil and its derivatives, It is a brown-black liquid.

Embodiment 2

[0047] Example 2 Preparation of Low Fluorescence Oil-based Lubricant for Drilling Fluid Based on Regenerated Grease and Its Derivatives

[0048] Mix 80g of waste oil, 5g of p-toluenesulfonic acid and 6g of triethanolamine to carry out esterification reaction, the reaction temperature is controlled at 140°C, and the reaction time is 4h;

[0049] Add 120 g of unrefined crude fatty acid methyl ester and 6 g of solid nitric acid to the reactants obtained above, and react at a temperature of 130 ° C for 1 h to obtain low fluorescent oil for drilling fluid based on regenerated oil and its derivatives base lubricant, which is a brown-black liquid.

Embodiment 3

[0050] Example 3 Preparation of Low Fluorescence Oil-based Lubricants for Drilling Fluids Based on Regenerated Grease and Its Derivatives

[0051] Mix 80g of waste oil, 5g of p-toluenesulfonic acid and 6g of triethanolamine to carry out esterification reaction, the reaction temperature is controlled at 140°C, and the reaction time is 4h;

[0052] Add 120 g of unrefined crude fatty acid methyl ester and 13 g of solid nitric acid to the reactants obtained above, and react at a temperature of 120 ° C for 3 hours to obtain low-fluorescence oil for drilling fluid based on regenerated oil and its derivatives base lubricant, which is a brown-black liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com