Extraction method of rubidium

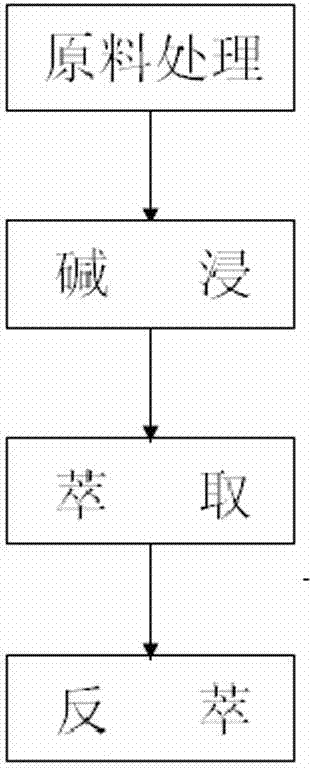

An extraction method and extraction technology are applied in the extraction field of rubidium, which can solve the problem that there is no one better occurrence form, and achieve the effects of short reaction time and improved leaching rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take 100g of mineral sample and 500ml of 120g / L NaOH solution to adjust the slurry, and then add it to the pressurized reaction kettle, the temperature is 160℃, and the time is 1h. After leaching and filtering, the filter residue can be used as cement raw material. The filtrate contains Rb 0.342g / L, and the leaching rate of rubidium reaches 84.79%. The above-mentioned filtrate was subjected to solvent extraction, the extractant was t-BAMBP and the amount of xylene was 1:2, the extraction ratio (O / A) was 3:1, the extraction time was 3min, and the number of extraction stages was 3, and the resulting Rb load The organic phase contains Rb 0.21g / L; the extraction rate is 92.23%. The Rb-loaded organic phase is back-extracted with HCl to obtain the RbCl solution; the back-extraction acid concentration is 2mol / L, the back-extraction time is 3 minutes, the number of back-extraction stages is 3, and the back-extraction ratio (O / A) is 7:1 . The water phase composition after strip...

Embodiment 2

[0035] Take 100g of 160-mesh ore sample and 500ml of 160g / L NaOH solution to adjust the slurry, and then add it to the pressurized reactor at a temperature of 180℃ and a time of 3h. After leaching and filtering, the filter residue can be used as cement raw material. The filtrate contains Rb 0.356g / L, and the leaching rate of rubidium reaches 86.7%. Solvent extraction of the above-mentioned filtrate, the extractant is t-BAMBP and the amount of xylene is 1:2, the extraction ratio (O / A) is 7:1, the extraction time is 5min, the number of extraction stages is 5, and the Rb load is obtained The organic phase contained 0.81g / L of Rb after washing, and the extraction rate was 99.3%. After washing, the organic phase loaded with Rb is back-extracted with HCl to obtain the RbCl solution; the concentration of the back-extraction acid is 5mol / L, the back-extraction time is 8min, the number of back-extraction stages is 5, and the back-extraction ratio (O / A) is 3 :1. The water phase composi...

Embodiment 3

[0037] Take 100g of the 260 mesh sample and 500ml NaOH+Na 2 CO 3 Mixed solution (NaOH and Na 2 CO 3 The mass ratio is 1:1), and the solution with a concentration of 180g / L is slurried, and then added to the pressurized reactor at a temperature of 180°C and a time of 4h. After leaching and filtering, the filter residue can be used as cement raw material. The filtrate contains Rb 0.369g / L, and the leaching rate of rubidium reaches 91.02%. The above-mentioned filtrate was subjected to solvent extraction, the extractant was t-BAMBP and the amount of xylene was 1:2, the extraction ratio (O / A) was 1:1, the extraction time was 2min, and the number of extraction stages was 7, and the resulting Rb load The organic phase contains Rb 0.645g / L, and the extraction rate is 99.3%. The Rb-loaded organic phase is back-extracted with HCl to obtain the RbCl solution; the back-extraction acid concentration is 4mol / L, the back-extraction time is 5min, the number of back-extraction stages is 7, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com