Double-orientation fiber-reinforced polypropylene randon copolymer three-layer composite tube

A fiber-reinforced, random copolymerization technology, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of the decrease of the expansion coefficient of the pipeline line, the decrease of the hoop pressure resistance performance, and the limitation of popularization and application, so as to improve the The effect of improving pressure resistance and impact resistance at low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

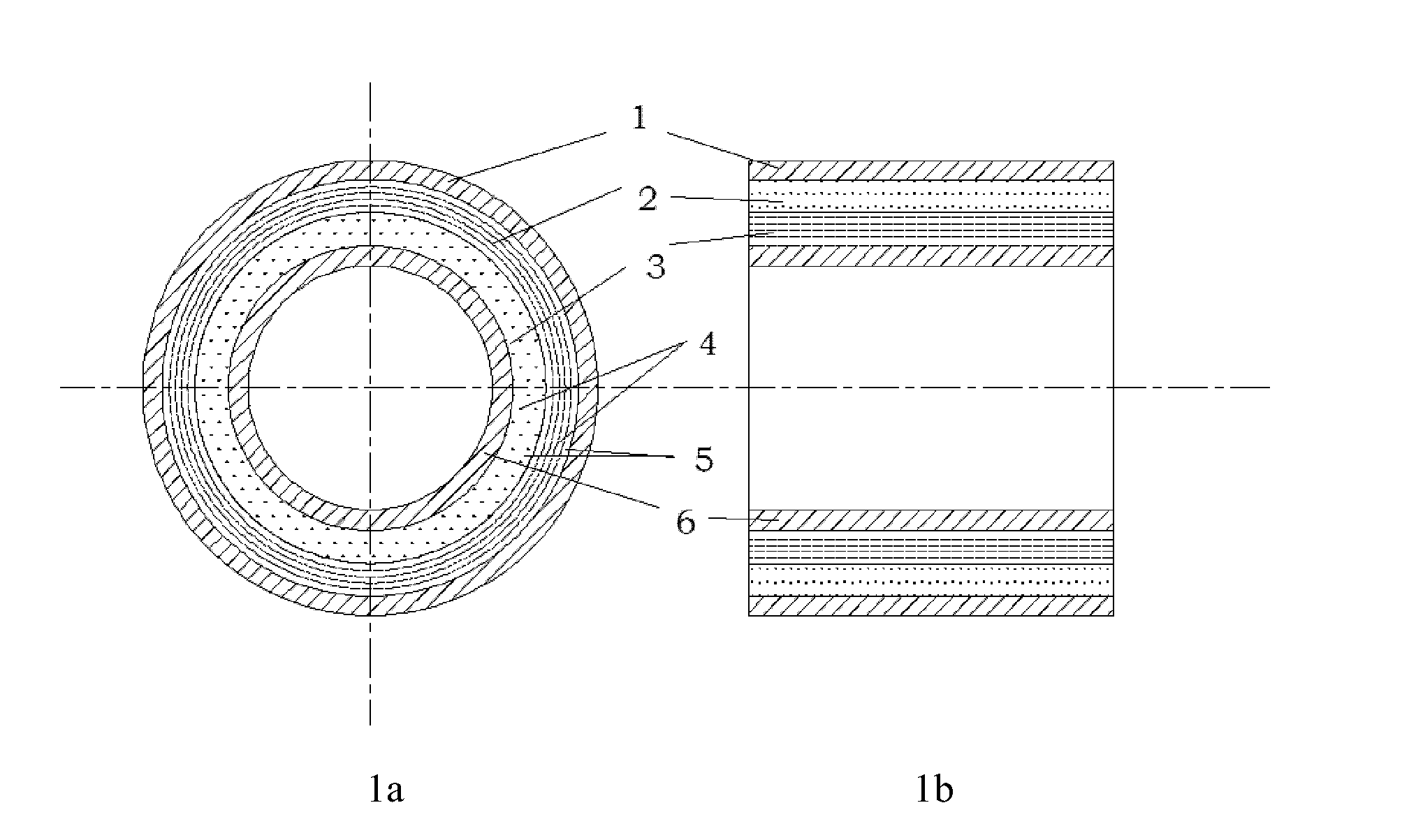

[0019] Please see attached figure 1 A double-oriented fiber-reinforced random copolymerized polypropylene three-layer composite pipe comprises a random copolymerized polypropylene pipe wall outer layer (1) and pipe wall inner layer (6) and a double-oriented fiber reinforced layer. It is characterized in that there are two layers of reinforcing layers of circumferential fiber reinforcement (2) and axial fiber reinforcement (3) between the pipe wall outer layer (1) and the pipe wall inner layer (6).

[0020] A double-oriented fiber-reinforced random copolymerized polypropylene three-layer composite pipe, the size of the pipe is φ90*10, the pipe wall is composed of 20% random copolymerized polypropylene outer layer, 20% random copolymerized polypropylene inner layer, 30% hoop fiber reinforcement, 30% axial fiber reinforcement. Wherein, the fiber content in both the hoop and axial fiber reinforced layers is 25%, the fiber length is 400μm-800μm, and 8% maleic anhydride grafted pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com