High-luminous-efficacy high-power light-emitting diode (LED) panel light

An LED light bar, high-power technology, applied in the field of LED lighting, can solve problems such as poor heat dissipation and low luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

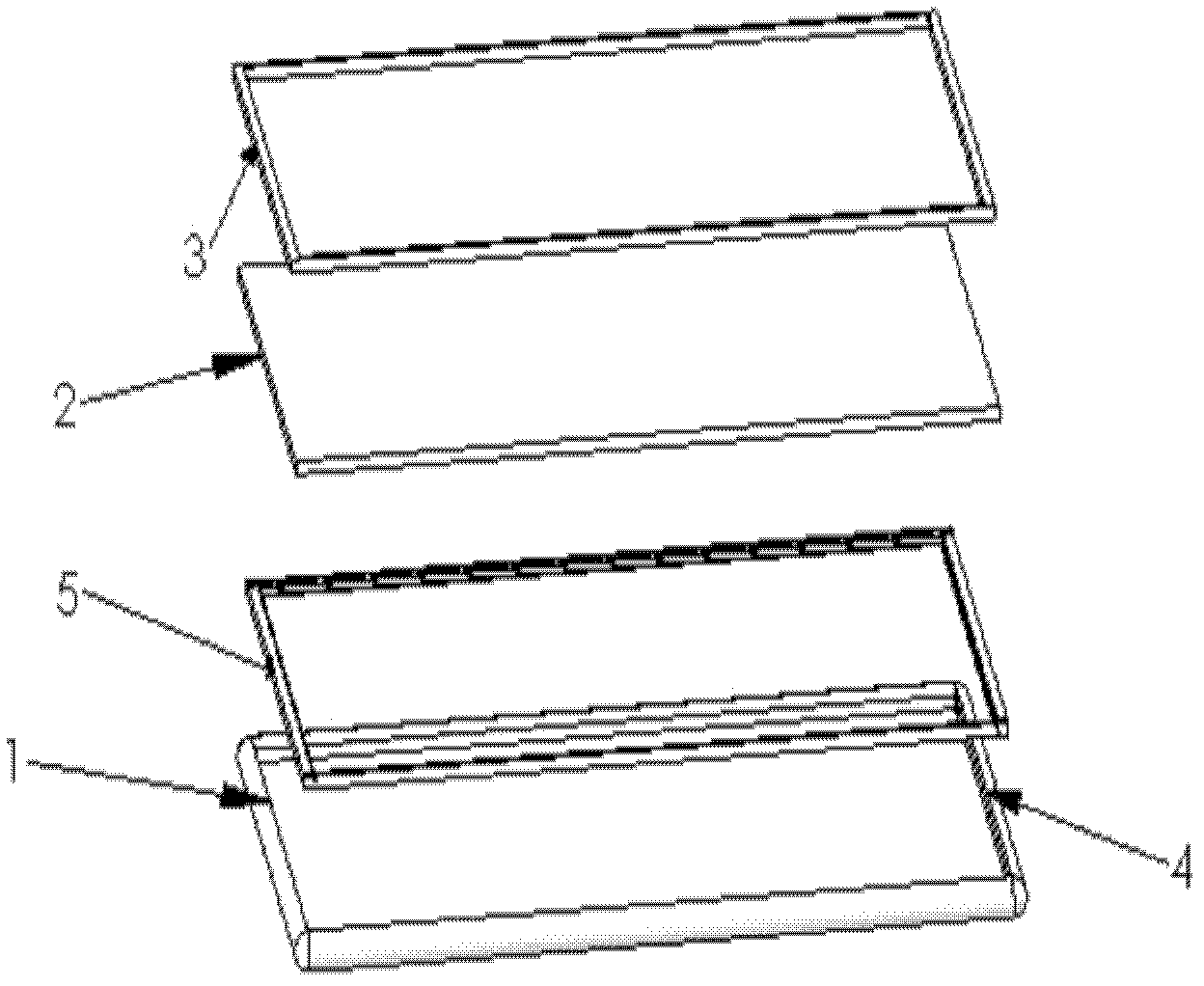

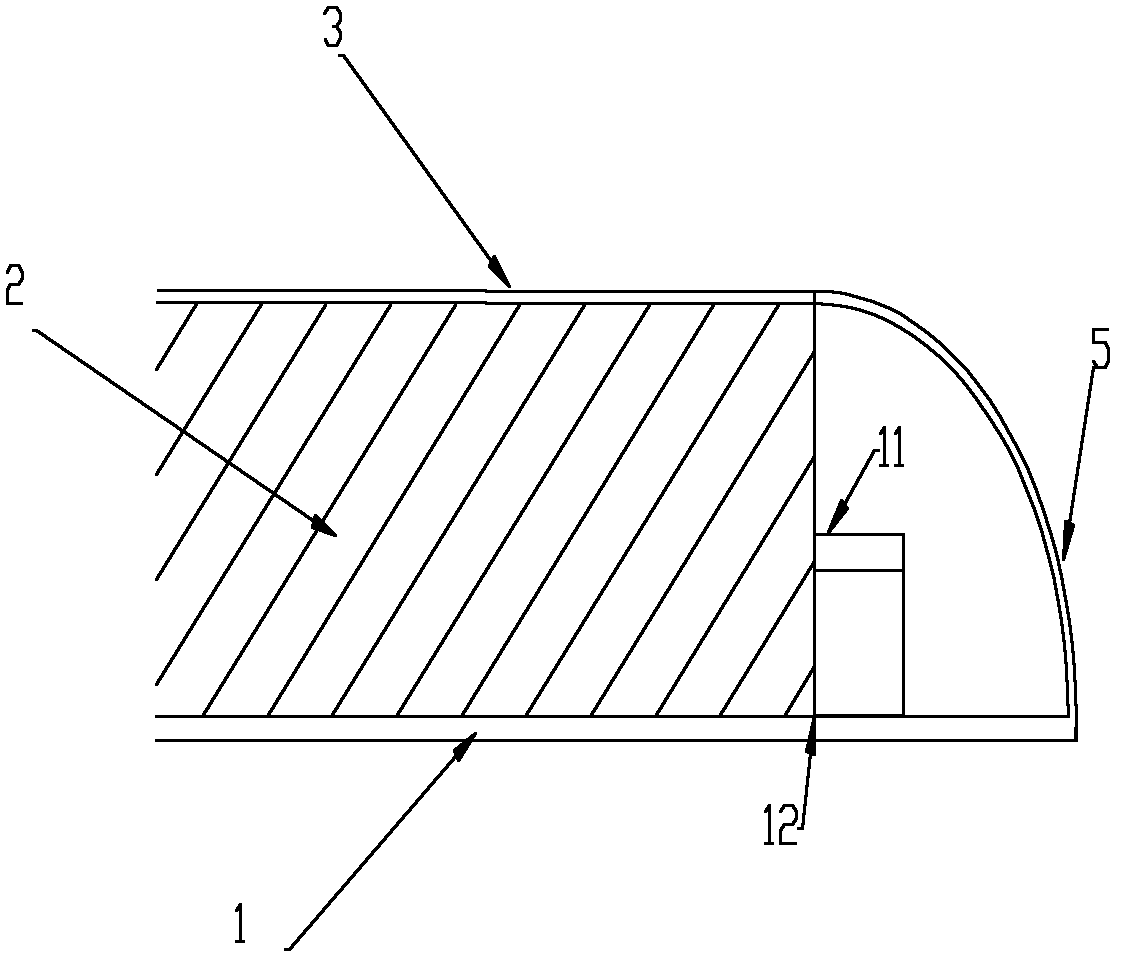

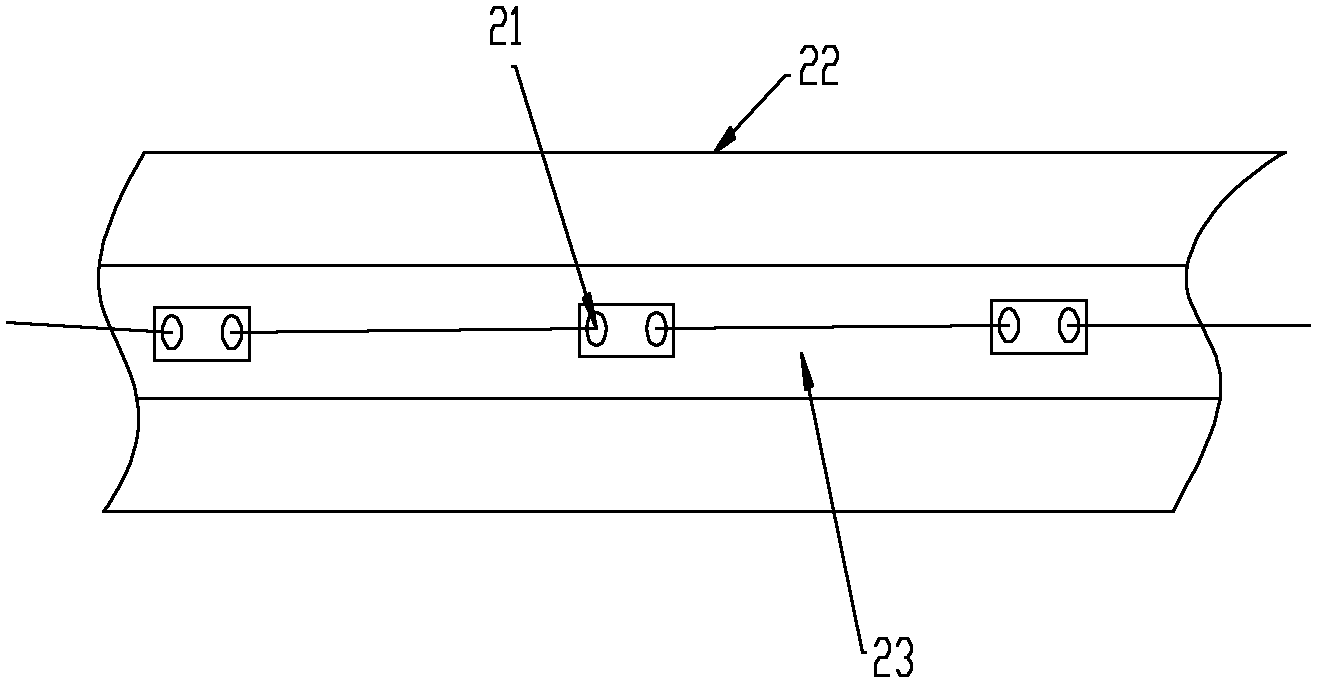

[0025] Such as figure 1 As shown, it is an overall structural diagram of a high-efficiency high-power LED panel light of the present invention. The panel light includes a base plate 1, a light guide plate 2, a panel 3, a reflector 4, an LED light bar 5, and a power supply 6, and adopts an aluminum substrate Die-casting is formed into the bottom plate 1 of the panel light, and there is an arc warp around the edge of the bottom plate. Use a vacuum ion coating machine to coat a mirror reflective film on the inner surface of the warp to form a reflector, and use a vacuum ion coating machine to coat the bottom plate. A layer of reflective film, the reflectivity of the reflective film gradually increases from the edge to the middle, the LED light bar 5 is installed on the edge of the bottom plate 1, and the light guide plate 2 doped with scattering particles with a refractive index close to the LED chip is installed on the bottom plate Above, the edges around the light guide plate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com