Scratch resistant and weather-resistant blending material with high brightness and metal texture

A metal texture, high brightness technology, applied in the field of polymer materials, can solve the problems affecting the mechanical properties of products, the surface scratch resistance is not enough, easy to oxidize and discolor, etc., to avoid the decline of metal luster, reduce surface flow marks, metal obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

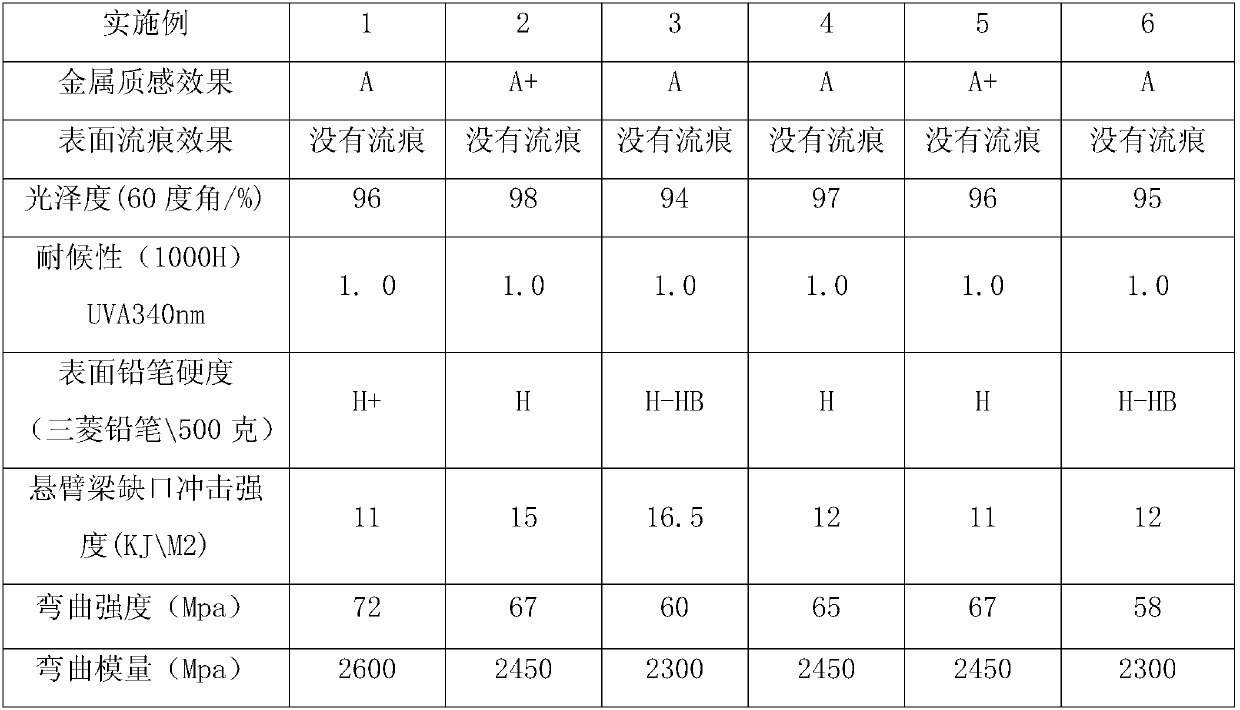

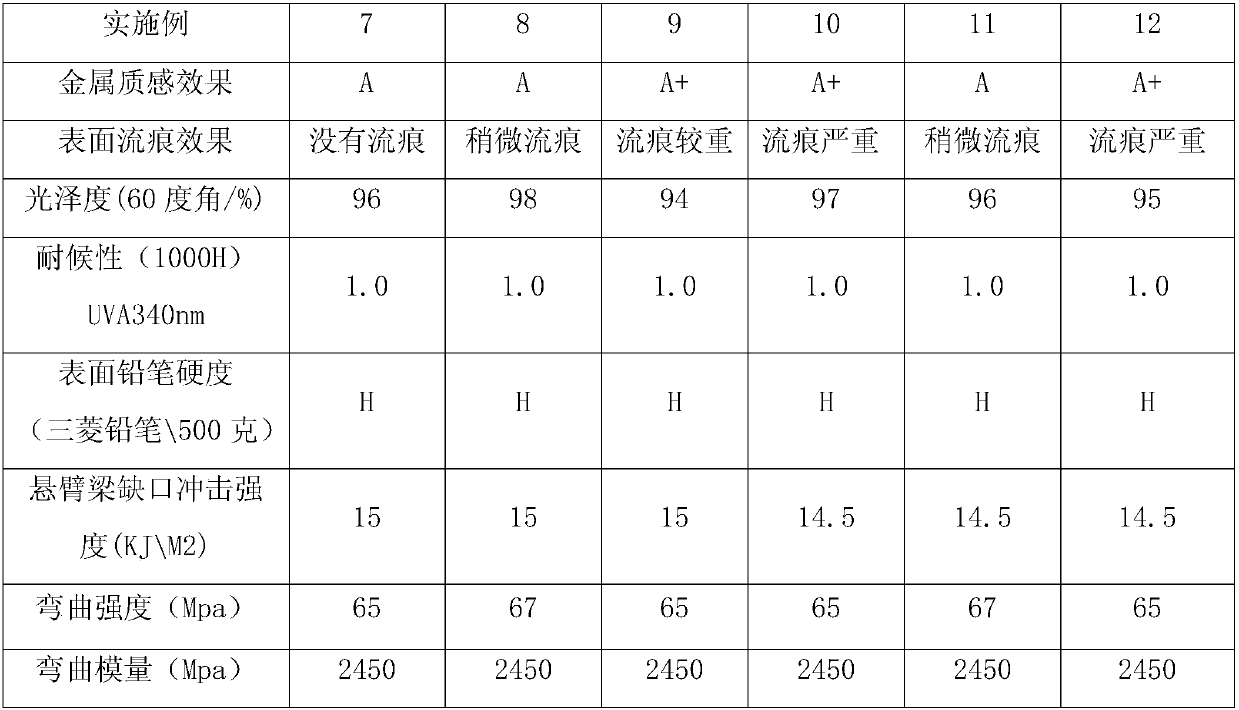

Examples

preparation example Construction

[0040] The preparation method of the scratch-resistant and weather-resistant blend material with high-brightness metallic texture comprises the following steps:

[0041] A. Place 0.2-1 parts of metallic pigments and 2-5 parts of compatibilizer in a three-necked bottle, mix well and stir for 20-40 minutes, then place for 1-3.5 hours to form the first mixture; further preferably , Stir 0.2-1 parts of metal pigment and 2-5 parts of compatibilizer for 30 minutes and then leave it for 2 hours;

[0042] B. Perform high-speed mixing of 40-60 parts of ASA resin, 40-60 parts of PMMA resin, 0.2-1 part of processing aid, 0.1-1 part of antioxidant and 0.2-1 part of weather resistance agent according to the proportion by weight. 400-500rpm, the mixing time is 60-90s; then, add the first mixture for low-speed mixing to form the second mixture, the rotating speed is 200-250rpm, and the mixing time is 10-20s;

[0043] C. Add the second mixture into a single-screw or twin-screw extruder, melt...

Embodiment 1

[0050] A scratch-resistant and weather-resistant blend material with a high-brightness metallic texture, which has the following components by weight: ASA resin 50kg; PMMA resin 50kg; antioxidant (1010) 0.2kg; antioxidant (168) 0.2 kg, hindered phenolic UV absorber 0.5kg; metallic effect pigment 0.3kg; processing aid EBS 0.2kg; compatibilizer KH550 or SAG 3kg;

Embodiment 2

[0052] A scratch-resistant and weather-resistant blend material with a high-brightness metallic texture, which has the following components by weight: ASA resin 60kg; PMMA resin 40kg; antioxidant (1010) 0.2kg; antioxidant (168) 0.2 kg, hindered phenolic UV absorber 0.5kg; metal pigment 0.3kg; processing aid EBS 0.2kg; compatibilizer KH550 or SAG 3kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com