Aeroengine vibration transducer double-wire checking and detecting method and implementation system thereof

A vibration sensor and aero-engine technology, which is used in vibration testing, machine/structural component testing, internal combustion engine testing, etc., can solve the problems that cannot be correctly judged by the calibrated vibration sensor, cannot reflect the system error of the vibration system, and achieve work The effect of improved efficiency, improved start-up sensitivity, and improved resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

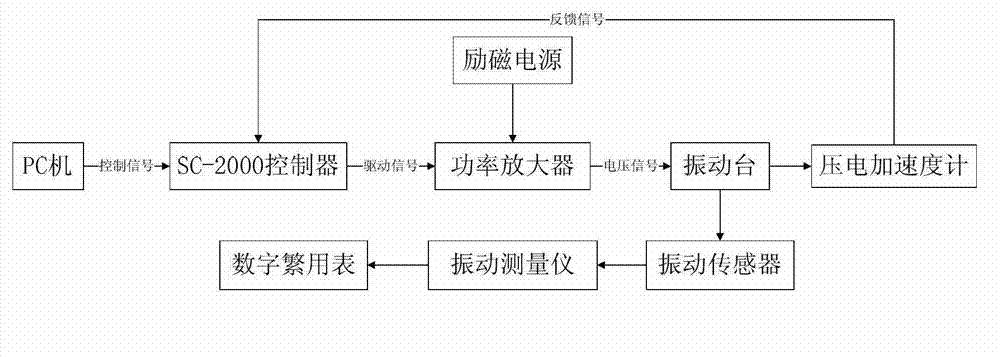

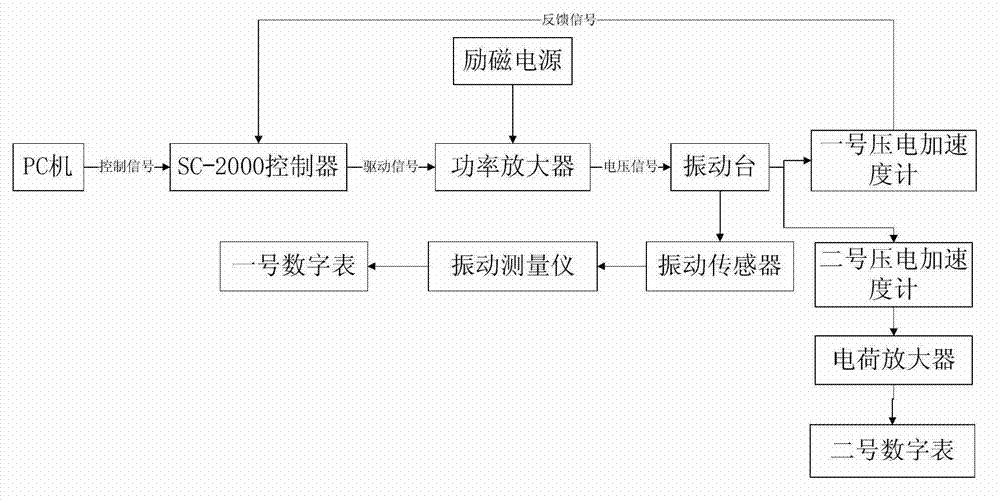

[0018] The two-line calibration detection system of the vibration sensor of the aero-engine of the present embodiment has a structure as attached figure 2 As shown, it is composed of a verification detection main system and a sub-system for verification and detection of the vibration system's own error. The verification detection main system includes a PC, an SC-200 controller, a power amplifier, an excitation power supply, and a D-10A standard Vibrating table vibrating table, measured vibration sensor, vibration measuring instrument, No. 1 digital display and No. 1 piezoelectric accelerometer, the output terminal of the control signal of the PC is connected with the input terminal of the SC-200 controller, and the output terminal of the power amplifier The input end is respectively connected to the drive control signal output end of the SC-200 controller and the excitation power output end, the power output end is connected to the driving motor of the vibrating table, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com