Model for researching jointed rock slope, and manufacturing method of the model

A technology of jointed rock and a manufacturing method, which is applied in the field of geotechnical engineering to achieve the effects of simple structure, low cost and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

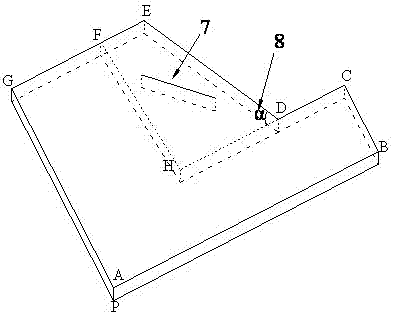

[0025] Example 1: Make a slope model with a dip angle of 70° and a single joint.

[0026] (1) According to the material ratio gypsum: barite: sand: water = 3:1:2:3 Weigh all kinds of materials, add 0.5% boric acid in the water according to the mass ratio, and stir evenly. Mix the granular material evenly, add water, stir quickly and evenly.

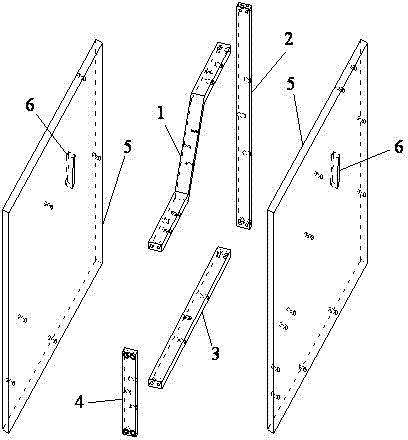

[0027](2) The four parts of the side shaping device are made of steel bars, the upper and lower bottom panels are made of resin boards, and there are prefabricated grooves in the resin boards. The dimensions of this slope model are: the length of the bottom surface is 40cm, and the vertical distance between the top surface and the bottom surface is 30cm, controlled by components 2 and 3 respectively. The length of the top surface is 22cm, the length of the broken bottom surface is 11cm, the slope height is 20cm, and the slope angle is 70°. The slope height and slope angle are controlled by the shape and size of component 1. The joints a...

Embodiment 2

[0029] Example 2: Make a slope model with a dip angle of 60° and a single joint.

[0030] (1) According to the material ratio gypsum: barite: sand: water = 1:1:1:1 Weigh all kinds of materials, add 0.5% boric acid in the water according to the mass ratio, and stir evenly. Mix the granular material evenly, add water, stir quickly and evenly.

[0031] (2) The four parts of the side shaping device are made of steel bars, the upper and lower bottom panels are made of resin boards, and there are prefabricated grooves in the resin boards. The dimensions of this slope model are: the length of the bottom surface is 50cm, and the vertical distance between the top surface and the bottom surface is 40cm, controlled by components 2 and 3 respectively. The length of the top surface is 24cm, the length of the bottom surface of the slope is 13cm, the slope height is 25cm, and the slope angle is 45°. The slope height and slope angle are controlled by the shape and size of component 1. The j...

Embodiment 3

[0033] Example 3: Make a slope model with a dip angle of 45° and a single joint.

[0034] (1) According to the material ratio gypsum: barite: sand: water = 2:1:1:2 Weigh various materials, add 0.5% boric acid in the water according to the mass ratio, and stir evenly. Mix the granular materials evenly, add water, stir quickly and evenly.

[0035] (2) The four parts of the side shaping device are made of steel bars, the upper and lower bottom panels are made of resin boards, and there are prefabricated grooves in the resin boards. The dimensions of this slope model are: the length of the bottom side is 65cm, and the vertical distance between the top surface and the bottom surface is 50cm, controlled by components 2 and 3 respectively. The length of the top surface is 25cm, the length of the bottom surface of the slope is 12cm, the slope height is 30cm, and the slope angle is 60°. The slope height and slope angle are controlled by the shape and size of component 1. The joints a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com