Organic electroluminescence device with high electronic filling efficiency and preparation method of organic electroluminescence device

An electroluminescent device and injection efficiency technology, which is applied in the fields of electro-solid devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as shortening the life of the device, improve luminous efficiency, improve electron transmission capacity, and improve electron injection. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with accompanying drawing:

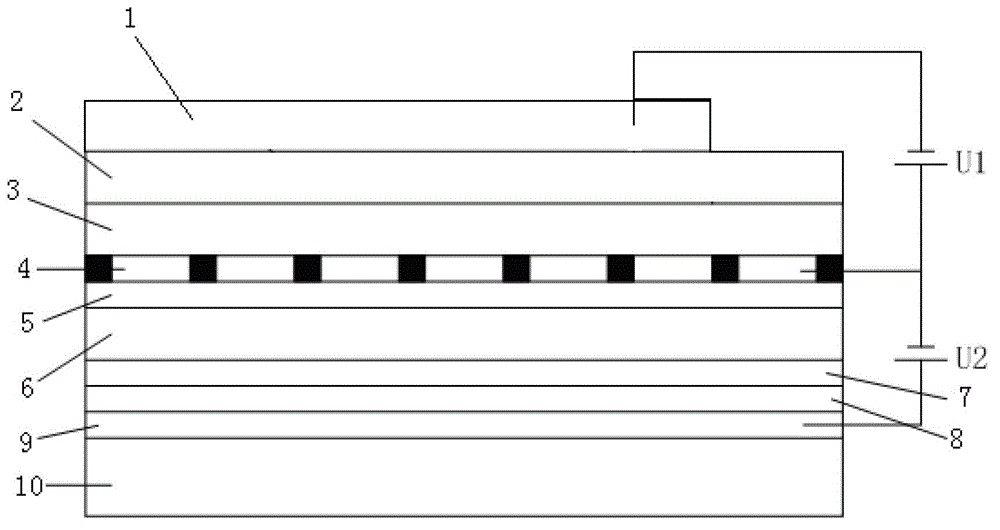

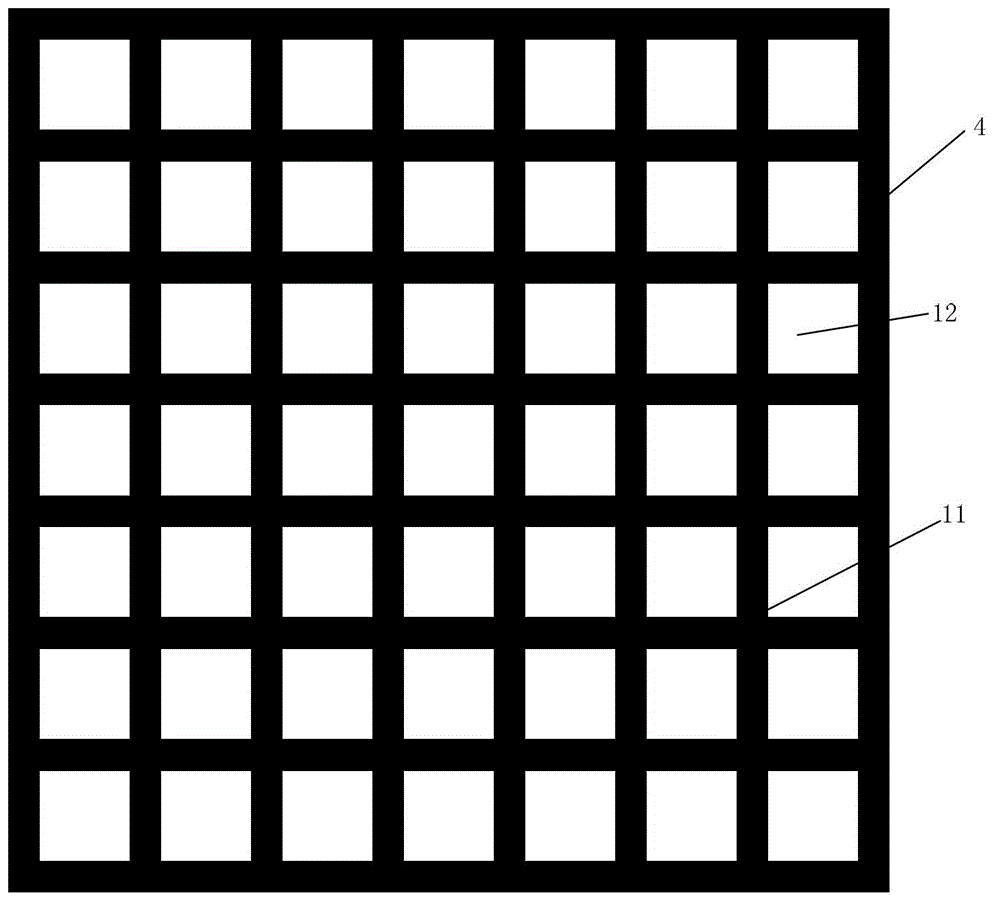

[0019] see figure 1 , the present invention includes a glass substrate 10, and an anode 9, a hole injection layer 8, a hole transport layer 7, a light emitting layer 6, an electron transport layer, an electron injection layer 2 and a cathode stacked sequentially on the glass substrate 10 from bottom to top 1; the electron transport layer is divided into an upper electron transport layer 3 and a lower electron transport layer 5, and between the upper electron transport layer 3 and the lower electron transport layer 5, Al with a grid structure of 3 to 5 nm in thickness is arranged The membrane electrode layer 4, the upper electron transport layer 3 and the lower electron transport layer 5 adopt the same organic material, and the thickness of the upper electron transport layer 3 is 4 to 5 times that of the lower electron transport layer 5, see figure 2 , the Al film ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com