Coarse cereal flour and manufacture method and application thereof

A technology for multigrain and flour, applied to multigrain flour and its production method and application field, can solve the problems of the appearance, color and luster of the multigrain dried noodles, poor taste, easy occurrence of insect pests, low addition ratio of the multigrain, etc., so as to achieve a rich flavor and good commerciality. , the effect of improving satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

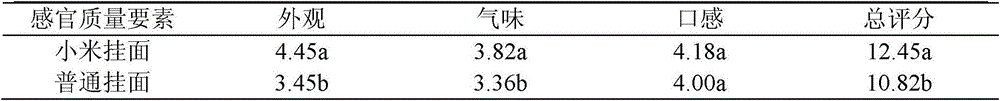

[0029] Embodiment 1, millet miscellaneous grain flour

[0030] 1) The dehulled millet grains were pulverized by an ultracentrifugal mill (ZM200, Germany Laich Company) with a screen diameter of 0.2 mm to obtain coarse millet powder.

[0031] 2) adding moisture to the twin-screw extruder through a liquid pump to the millet coarse powder obtained in step 1), so that the mass percentage of moisture in the material is 15%, and then adopt the DSE produced by Brabender Food Instrument Company of Germany -25 co-rotating twin-screw extruder for extrusion and puffing, the barrel temperature of the extruder is: 70°C, 100°C, 140°C, 150°C, 160°C, the hole diameter of the die used for extrusion is 4.0mm, Extruded and extruded, then cut by a cutter to obtain regular, uniform, and uniformly sized extruded particles.

[0032] 3) Dry the extrudate obtained in step 2) in a drying oven at 40° C., reduce the moisture content of the extrudate to 10.00%, and then pulverize it with an ultra-centrif...

Embodiment 2

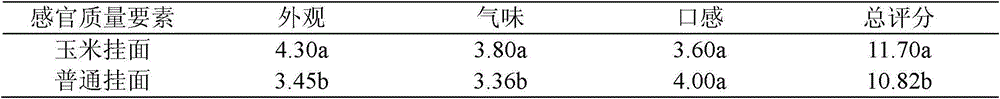

[0044] Embodiment 2, miscellaneous corn flour

[0045] 1) The corn kernels are ground with an experimental mill (Wuxi Xiliang Machinery Manufacturing Co., Ltd., LRMM8040-3-D type), and passed through a 2 mm sieve to obtain corn meal.

[0046]2) Add water to the twin-screw extruder through a liquid pump to the corn meal obtained in step 1), so that the mass percentage of water in the material is 20%, and use DSE produced by Brabender Food Instruments Company of Germany to -25 co-rotating twin-screw extruder for extrusion and puffing, the barrel temperature of the extruder is: 110°C, 140°C, 180°C, 190°C, 200°C, the diameter of the die head used for extrusion is 6.0mm, Regular, uniform and consistent extrudate particles are obtained after cutting by a cutter.

[0047] 3) Dry the extrudate obtained in step 2) in a drying oven at 60° C. to reduce the moisture content of the extrudate to 9.86%, and then pulverize it using an ultra-centrifugal pulverizer (ZM200, Laich Company, Germa...

Embodiment 3

[0056] Embodiment 3, buckwheat miscellaneous grain flour

[0057] 1) The dehulled buckwheat grains were pulverized by an ultracentrifugal pulverizer (ZM200, Germany Laich Company) with a sieve diameter of 0.25 mm to obtain coarse buckwheat flour.

[0058] 2) Add moisture to the twin-screw extruder through a liquid pump to the buckwheat coarse powder gained in step 1, so that the mass percentage of moisture in the material is 18%, and then use the DSE produced by Brabender Food Instruments Co., Ltd., Germany. -25 co-rotating twin-screw extruder for extrusion and puffing, the temperature of the barrel of the extruder is as follows: 90°C, 110°C, 160°C, 170°C, 180°C, the diameter of the die head used for extrusion is 5.0mm, Regular, uniform and consistent extrudate particles are obtained after cutting by a cutter.

[0059] 3) The extrudate obtained in step 2) is dried in a drying oven at 60° C., so that the moisture content of the extrudate is reduced to 9.00%. Utilize ultra-cen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com