Plant drink and preparation method thereof

A plant-based beverage and raw material technology, applied in the field of beverages, can solve the problems of single product specification, weak channel expression, narrow consumer positioning, etc., and achieve the effect of sweet and refreshing entrance, pleasant smell and broad market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

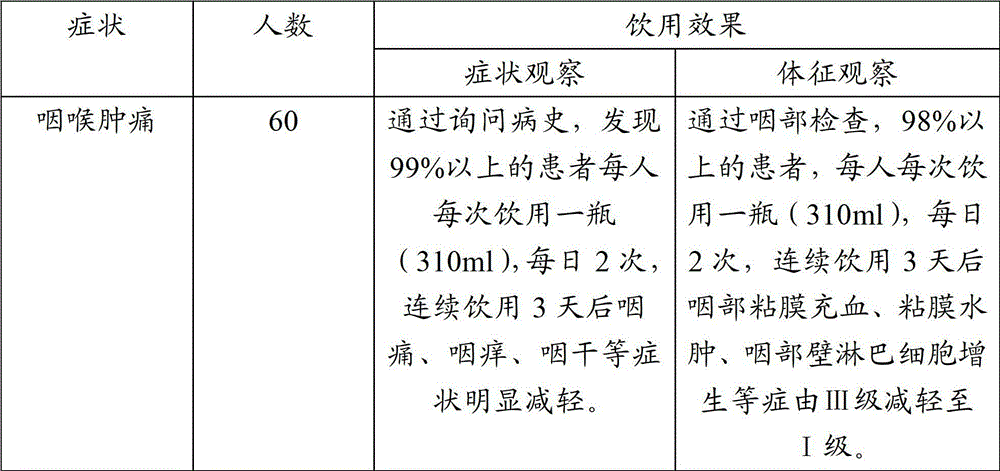

Examples

Embodiment 1

[0020] Weigh the raw materials that account for the following weight percentages of the total weight of the plant beverage: 0.8% of chrysanthemum, 0.5% of lotus seeds, 0.04% of tangerine peel, 0.05% of fat sea, 0.12% of medlar and 0.08% of licorice, add 15 times of water, and set the temperature at 80°C Soak for 25 minutes, filter with a microporous membrane, and then concentrate the obtained filtrate in a water bath at 100°C to a relative density of 1.02g / mL to obtain an extract; then weigh 3.0% of white sugar and 0.07% of acesulfame potassium, and add an appropriate amount of Dissolve in water, mix evenly with the prepared extract, filter through a microporous membrane, constant volume, pack in cans, and sterilize at a temperature of 121°C and a pressure of 0.12mPa for 15 minutes to obtain the product.

[0021] Place the beverage for 3 months under accelerated test conditions, the accelerated conditions are temperature 37 ± 2 ° C, relative humidity 75 ± 5%, and the samples pl...

Embodiment 2

[0023] Weigh the raw materials accounting for the following weight percentages of the total weight of the plant beverage: 0.7% of chrysanthemum chrysanthemum, 0.4% of lotus seeds, 0.06% of tangerine peel, 0.07% of fat sea, 0.10% of medlar and 0.10% of licorice, add 15 times of water, at 80 ℃ Soak for 25 minutes, filter with a microporous membrane, and then concentrate the obtained filtrate in a water bath at 100°C to a relative density of 1.02g / mL to obtain an extract; then weigh 2.0% of white sugar and 0.08% of acesulfame potassium, and add an appropriate amount of Dissolve in water, mix evenly with the prepared extract, filter through a microporous membrane, constant volume, pack in cans, and sterilize at a temperature of 121°C and a pressure of 0.12mPa for 15 minutes to obtain the product.

[0024] Place the beverage for 3 months under accelerated test conditions, the accelerated conditions are temperature 37 ± 2 ° C, relative humidity 75 ± 5%, and the samples placed for 0 m...

Embodiment 3

[0026] Weigh the raw materials accounting for the following weight percentages of the total weight of the plant beverage: 0.9% of chrysanthemum chrysanthemum, 0.6% of lotus seeds, 0.03% of tangerine peel, 0.06% of fat sea, 0.08% of medlar and 0.12% of licorice, add 15 times of water, at 80 ℃ Soak for 25 minutes, filter with a microporous membrane, and then concentrate the obtained filtrate in a water bath at 100°C to a relative density of 1.02g / mL to obtain an extract; then weigh 4.0% of white sugar and 0.06% of acesulfame potassium, and add an appropriate amount of Dissolve in water, mix evenly with the obtained extract, filter through a microporous membrane, constant volume, pack in cans, and sterilize at 121°C and 0.12mPa for 15 minutes to obtain the product.

[0027] Place the beverage for 3 months under the accelerated test conditions, the accelerated conditions are temperature 37±2°C, relative humidity 75±5%, and the samples placed for 0 months, 1 month, 2 months, and 3 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com