Injection molding device and injection molding method of online mixing and preparing high-performance microcellular foaming plastic

A technology of microcellular foamed plastics and injection molding equipment, applied in the field of microcellular foamed plastics molding, can solve the problems of different pore sizes, inability to disperse, and unstable cell density, so as to improve quality and performance, and avoid gas Escape, enhance solubility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

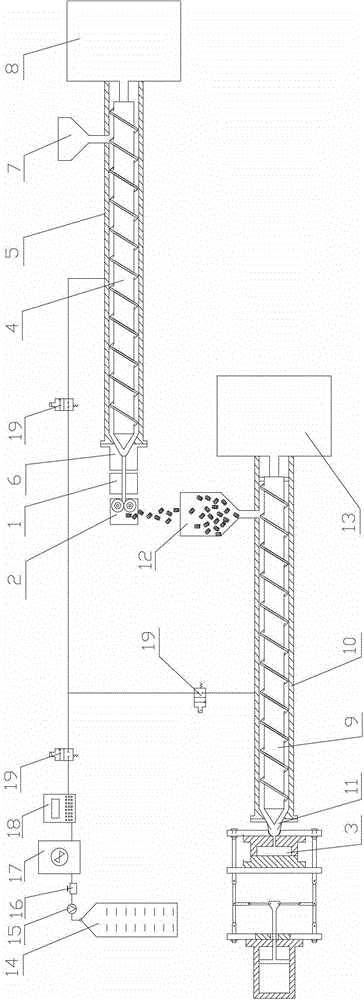

[0022] In this embodiment, an injection molding device for preparing high-performance microcellular foamed plastics by on-line compounding, such as figure 1 As shown, it includes an extrusion foaming unit, a supercritical fluid delivery unit and an injection foaming unit. The output end of the extrusion foaming unit is successively provided with a thermostat 1 and a pelletizer 2. The feed end of the foam unit is connected, the fluid outlet end of the supercritical fluid delivery unit is respectively connected with the extrusion foam unit and the injection foam unit through pipes, and the outlet end of the injection foam unit is connected with the mold cavity 3 .

[0023] The extrusion foaming unit is a single-screw extruder, including an extrusion screw 4, an extrusion barrel 5, an extrusion head 6, an extrusion hopper 7 and an extrusion screw power mechanism 8, and the extrusion screw is arranged on the extrusion material In the barrel, the extruder head and the extrusion scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com