Production method and structure of airtight diving suit

A manufacturing method, a technology for wetsuits, applied in chemical instruments and methods, underwater operation equipment, ships, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

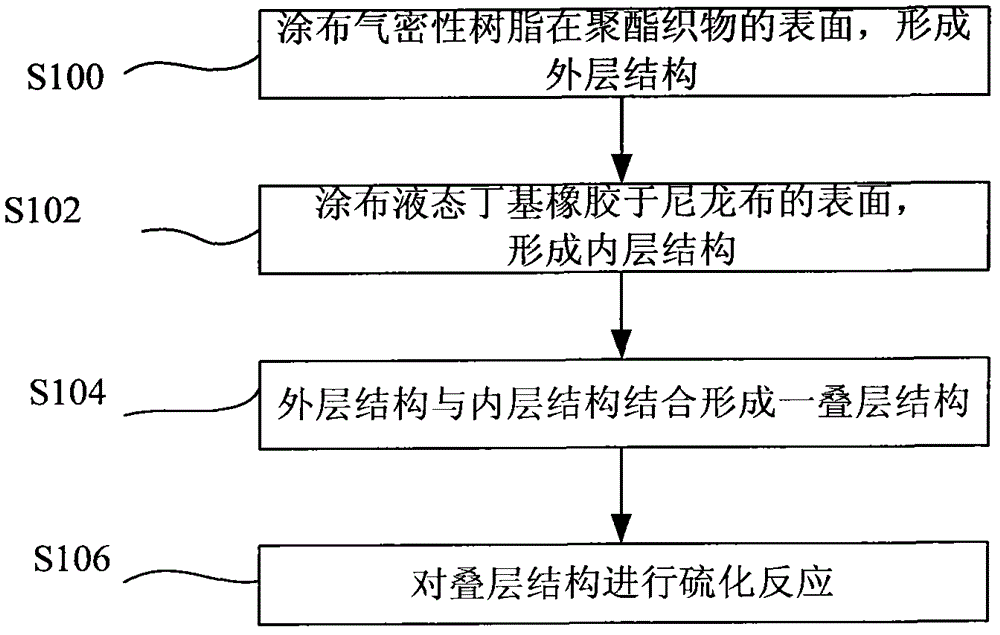

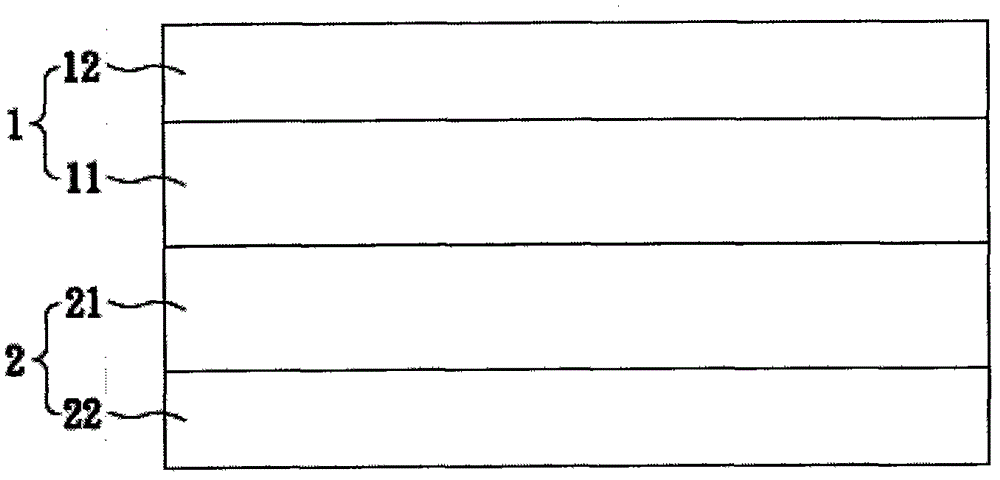

[0032] Please refer to figure 1 and figure 2 , the present invention proposes a method for manufacturing an airtight diving suit, which includes the following steps: first, as described in step S100, on the surface of the polyester fabric 12, the airtight resin is multi-layer coated The layer is coated on the surface of a high-denier polyester fabric 12 to form an outer layer structure 1. The airtight resin is prepared by cutting solid butyl rubber into fine pieces and mixing it with toluene. Next, as described in step S102 , a low denier nylon cloth 22 is taken, and multiple layers of liquid butyl rubber are coated on the low denier nylon cloth 22 to form an inner layer structure 2 . As described in step S104, the outer layer structure 1 and the inner layer structure 2 are combined to form a laminated structure, and then as described in step S106, vulcanization equipment (for example: a continuous vulcanizing machine for special rubber) is used for the laminated structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com