Method for synthesizing highly ordered super-microporous silicon dioxide

A silica and highly ordered technology, which is applied in the field of synthetic ultra-microporous silica, can solve the problems of low commercialization of template agents, unsuitability for large-scale production and application, and difficulty in purchasing, etc., achieving low cost, The effect of high order and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

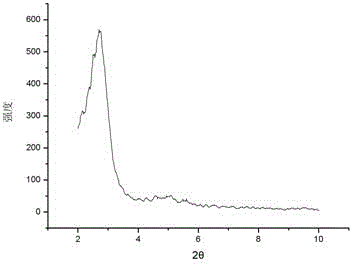

[0023] At room temperature, dissolve 1.12g of dedecyltrimethylammonium bromide and 0.136g of sodium octyl sulfate in 30ml of water, stir for 0.5h to obtain solution A, and take another 1.72g of Na 2 SiO 3 9H 2 Dissolve O in 30ml of water to obtain solution B; quickly mix solutions A and B, and add 2 mol / L sulfuric acid solution drop by drop to the above mixture under vigorous stirring until the pH is between 9-10; then at 80°C Constant temperature in the oven for 70-75 hours, the obtained solid precipitate is filtered, washed and dried in the air to obtain a composite product; the composite product is heated to 530-560°C in the air at a speed of 1.5°C / min, The product was obtained at constant temperature for 3-5 hours. XRD spectrum as figure 2 . Diffraction peaks appear around 2θ of 3, but the peaks are too broad to be indexed. The unit cell parameter a=3.13nm was calculated according to the d value on XRD. N 2 The BET surface area measured by adsorption-desorption met...

Embodiment 2

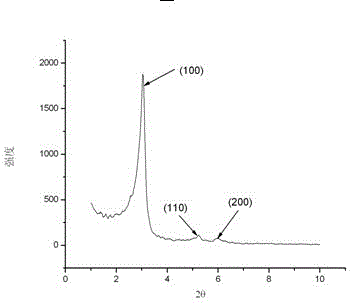

[0025] At room temperature, dissolve 1.12g of dedecyltrimethylammonium bromide and 0.180g of sodium octyl sulfate in 30ml of water, stir for 0.5h to obtain solution A, and take another 1.72g of Na 2 SiO 3 9H 2 Dissolve O in 30ml of water to obtain solution B; quickly mix solutions A and B, and add 2 mol / L sulfuric acid solution drop by drop to the above mixture under vigorous stirring until the pH is between 9-10; then at 80°C Constant temperature in the oven for 70-75 hours, the obtained solid precipitate is filtered, washed and dried in the air to obtain a composite product; the composite product is heated to 530-560°C in the air at a speed of 1.5°C / min, The product was obtained at constant temperature for 3-5 hours. XRD spectrum as image 3 . There are three obvious diffraction peaks in the figure, and the position index of the diffraction peak 2θ is confirmed as a two-dimensional hexagonal structure (2D-P6mm), and the three diffraction peaks correspond to the (100) (11...

Embodiment 3

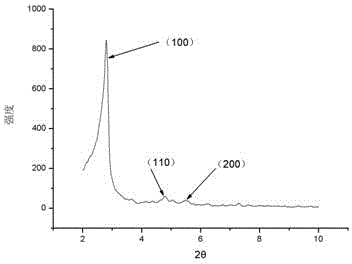

[0027] At room temperature, dissolve 1.12g of dedecyltrimethylammonium bromide and 0.278g of sodium octyl sulfate in 30ml of water, stir for 0.5h to obtain solution A, and take another 1.72g of Na 2 SiO 3 9H 2 Dissolve O in 30ml of water to obtain solution B; quickly mix solutions A and B, and add 2 mol / L sulfuric acid solution drop by drop to the above mixture under vigorous stirring until the pH is between 9-10; then at 80°C Constant temperature in the oven for 70-75 hours, the obtained solid precipitate is filtered, washed and dried in the air to obtain a composite product; the composite product is heated to 530-560°C in the air at a speed of 1.5°C / min, The product was obtained at constant temperature for 3-5 hours. XRD spectrum as Figure 4. There are three obvious diffraction peaks in the figure, and the position index of the diffraction peak 2θ is confirmed as a two-dimensional hexagonal structure (2D-P6mm), and the three diffraction peaks correspond to the (100) (11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com