Patents

Literature

30 results about "SODIUM OCTYL SULFATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium octyl sulfate - Green circle - The chemical has been verified to be of low concern based on experimental and modeled data. from EPA Safer Choice Literature

Rolled Copper or Copper Alloy Foil with Roughened Surface and Method of Roughening Rolled Copper or Copper Alloy Foil

ActiveUS20090162685A1Improve featuresInhibition formationPrinted circuit aspectsPrinted circuit manufactureTin platingCopper sulfate

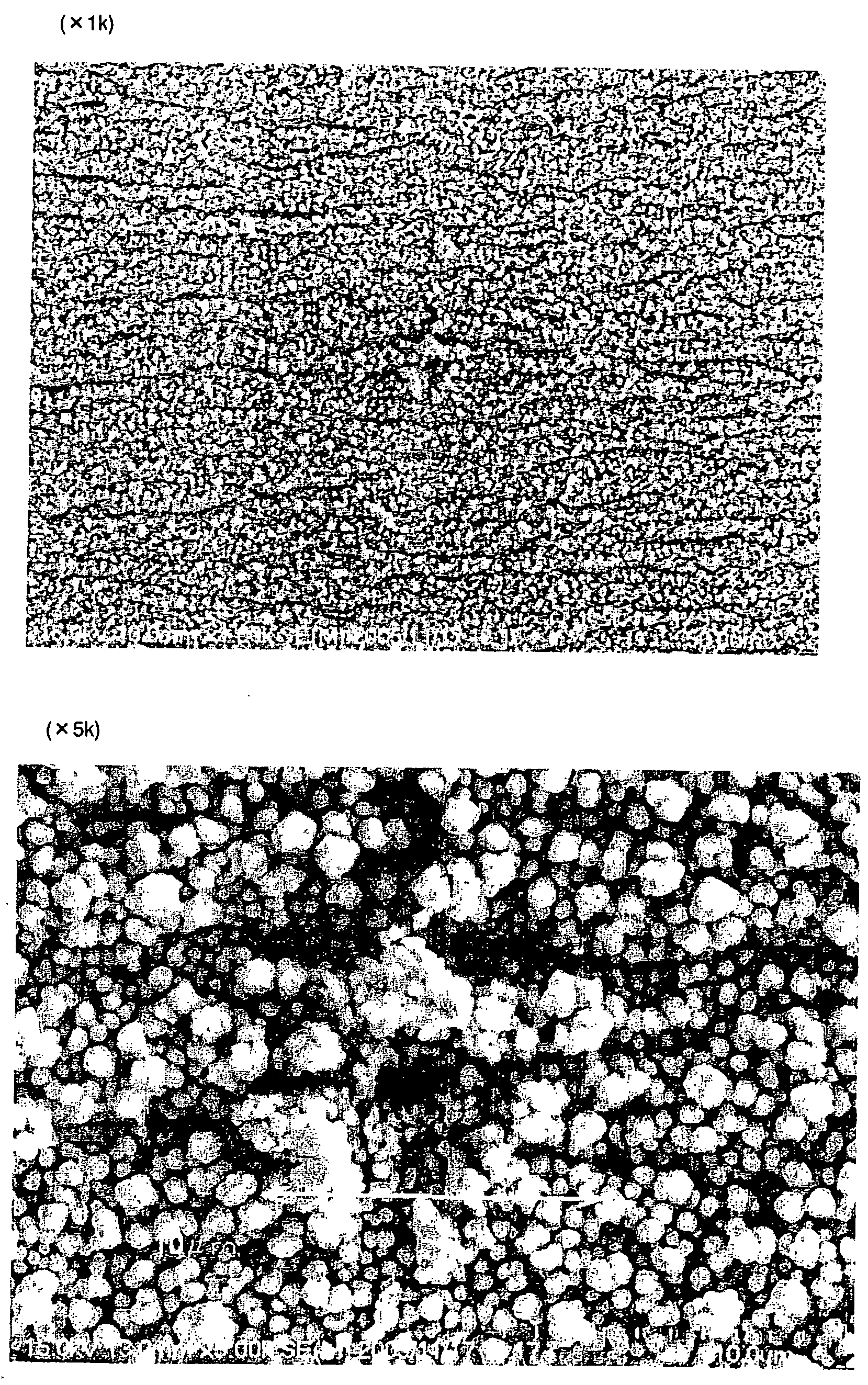

Provided is a rolled copper or copper alloy foil having a roughened surface formed of fine copper particles, obtained by subjecting a rolled copper or copper alloy foil to roughening plating with a plating bath containing copper sulfate (Cu equivalent of 1 to 50 g / L), 1 to 150 g / L of sulfuric acid, and one or more additives selected among sodium octyl sulfate, sodium decyl sulfate, and sodium dodecyl sulfate under the conditions of a temperature of 20 to 50° C. and a current density of 10 to 100 A / dm2. The provided rolled copper or copper alloy foil subject to roughening is reduced in craters which are obvious defects unique to rolled copper or copper alloy foils having a roughened surface, has high strength, adhesive strength with the resin layer, acid resistance and anti-tin plating solution properties, high peel strength, favorable etching properties and gloss level, and also suits for use in producing a flexible printed wiring board capable of bearing a fine wiring pattern. Additionally provided is a method of roughening the rolled copper or copper alloy foil.

Owner:JX NIPPON MINING& METALS CORP

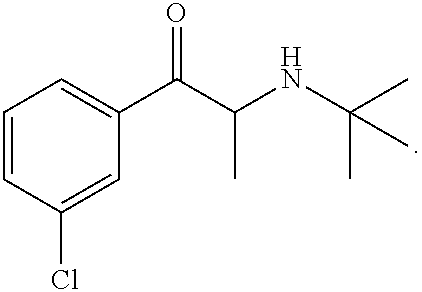

Topical formulation

ActiveUS20110028460A1Improve throughputBiocidePeptide/protein ingredientsSodium acetateSODIUM LAURYL SULFOACETATE

It has been discovered that certain combinations compounds are excellent penetration enhancers and, as such, can be incorporated in a topical formulation to facilitate administration of active agents. The increased penetration enhancement can also lead to a reduction in the total concentration of skin irritants in the formulation. There is described herein a topical formulation comprising (i) at least one active agent; (ii) a first compound, and (iii) a second compound, wherein the first compound and second compound are different, and each is selected from the group consisting of N-lauroyl sarcosine, sodium octyl sulfate, methyl laurate, isopropyl myristate, oleic acid, glyceryl oleate and sodium lauryl sulfoacetate.

Owner:CRESCITA THERAPEUTICS INC

Topical formulation

ActiveUS8343962B2Improve throughputBiocidePeptide/protein ingredientsSODIUM LAURYL SULFOACETATEActive agent

It has been discovered that certain combinations compounds are excellent penetration enhancers and, as such, can be incorporated in a topical formulation to facilitate administration of active agents. The increased penetration enhancement can also lead to a reduction in the total concentration of skin irritants in the formulation. There is described herein a topical formulation comprising (i) at least one active agent; (ii) a first compound, and (iii) a second compound, wherein the first compound and second compound are different, and each is selected from the group consisting of N-lauroyl sarcosine, sodium octyl sulfate, methyl laurate, isopropyl myristate, oleic acid, glyceryl oleate and sodium lauryl sulfoacetate.

Owner:CRESCITA THERAPEUTICS INC

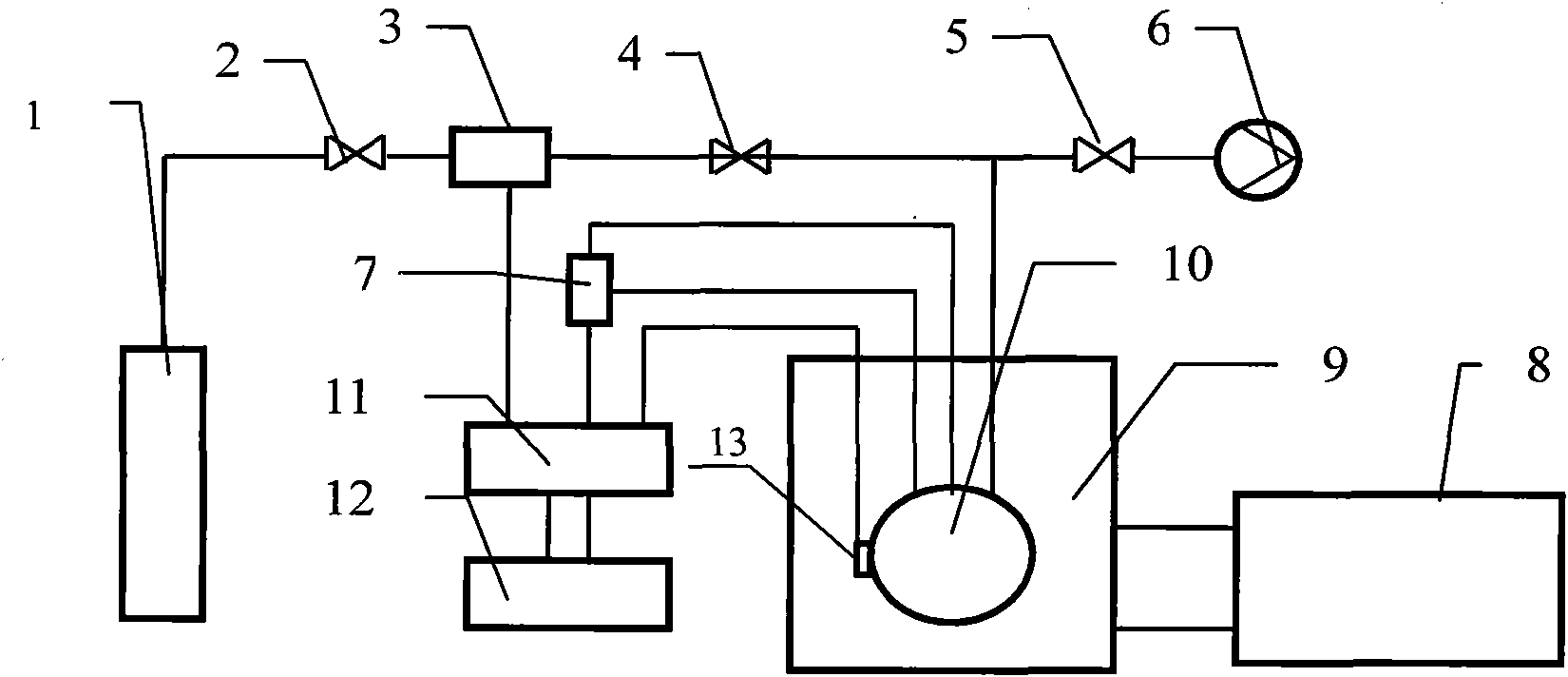

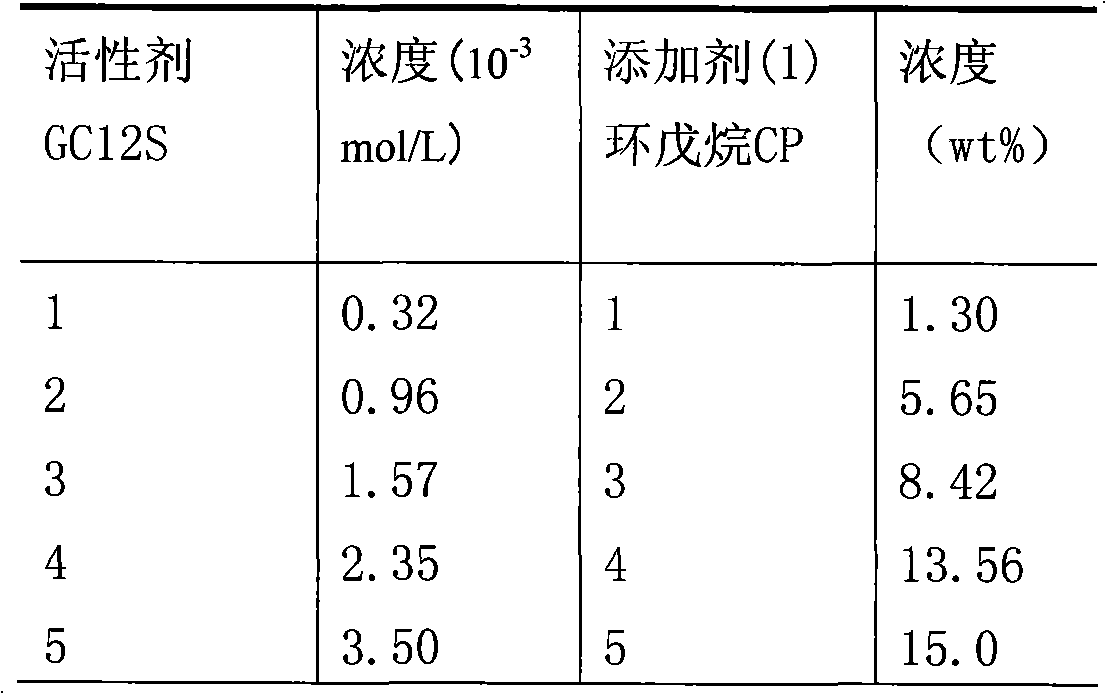

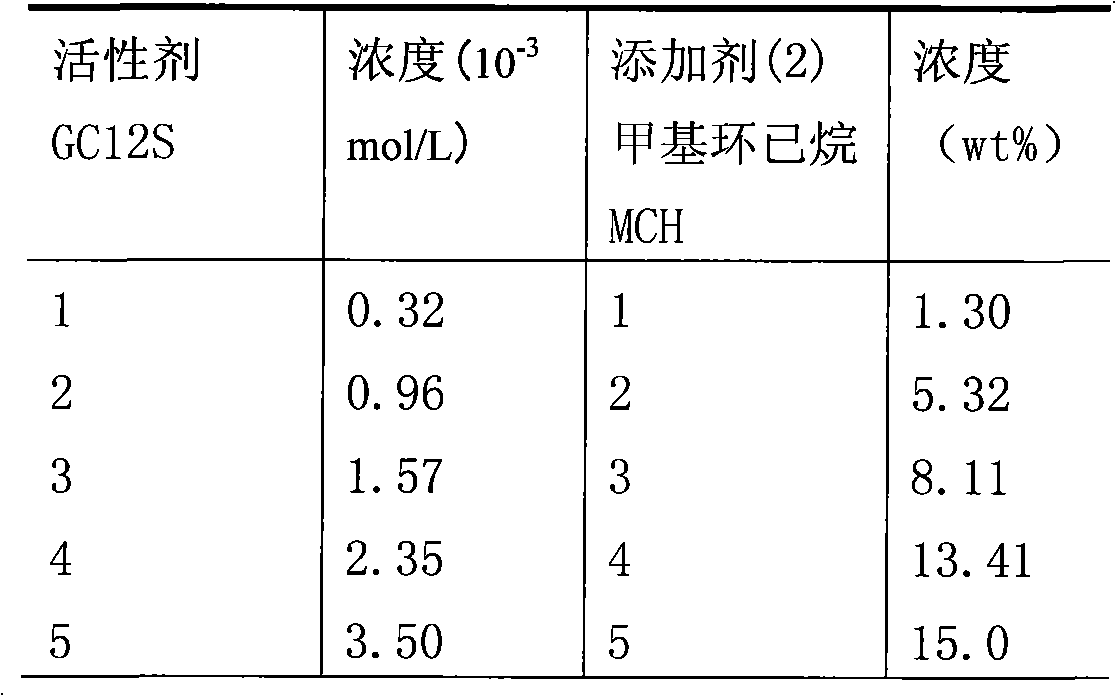

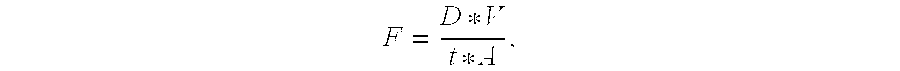

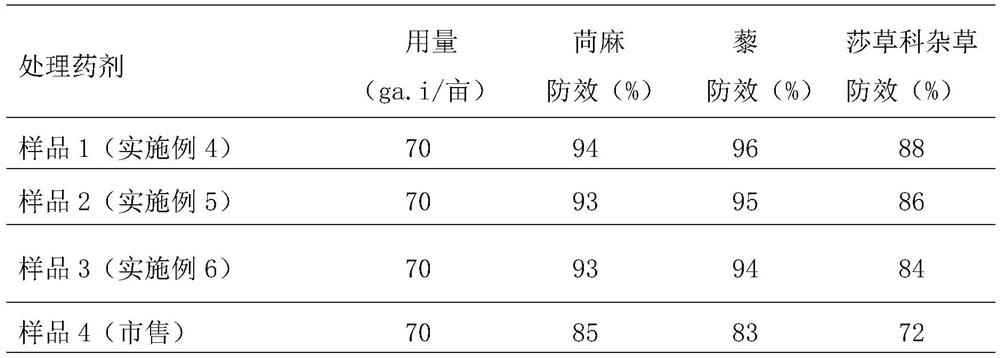

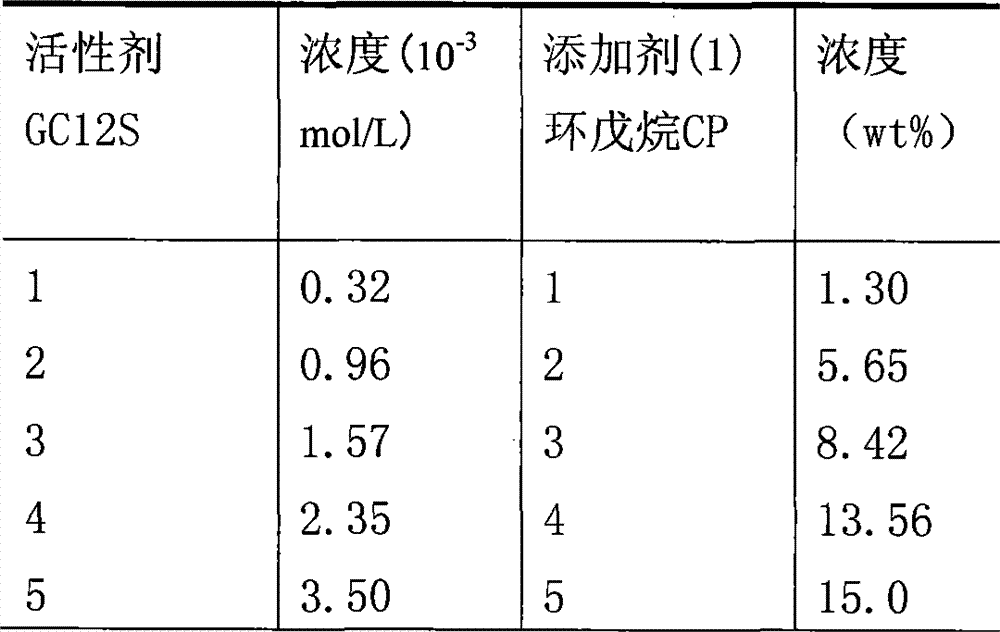

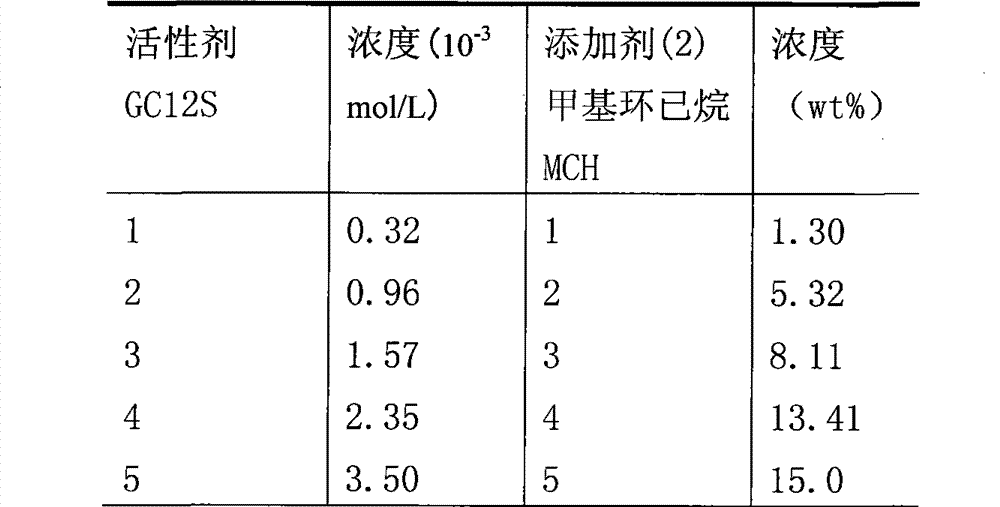

Method for preparing composite hydrate accelerant

The invention relates to a method for preparing a composite hydrate accelerant. The composite accelerant is characterized by being prepared by mixing cyclopentane or methyl cyclohexane serving as a kinetic accelerant and 2-butyl octyl sodium sulfate serving as a surfactant, wherein the percentage by mass of the cyclopentane or methyl cyclohexane in a solvent is 1.3 to 15.0, and the concentration of the surfactant 2-butyl octyl sodium sulfate in the solvent is 0.32*10<-3> to 9.5*10<-3> mol / L; and 0.02 to 0.78 mass percent of sodium chloride is added into the mixture. In the method, a high-pressure gas cylinder is taken as a gas source, a pressure is properly adjusted through a pressure adjustment valve, consumed gas is metered by a mass flow meter, a temperature and the pressure in a reactor are monitored by pressure and temperature transducers, and the temperature of liquid in a water tank is controlled by means of a thermostatic water bath, so that the temperature in the reactor is adjusted; and data is acquired by a data acquisition system and a computer, and the forming condition of a hydrate in the reactor is monitored by a photoelectric lens. The method for preparing the composite hydrate accelerant not only can reduce the forming condition of the hydrate, but also can shorten the formation time of the hydrate and improve the gas storage capacity of the hydrate.

Owner:溧阳常大技术转移中心有限公司

Topical formulation including diclofenac, or a pharmaceutically acceptable salt thereof

InactiveUS7795309B2Improve throughputOrganic active ingredientsBiocideSODIUM LAURYL SULFOACETATEMethyl laurate

There is described a topical formulation. The topical formulation comprises: (i) diclofenac or a pharmaceutically acceptable salt thereof, (ii) a first compound, and (iii) a second compound. The first compound and second compound are different, and each is selected from the group consisting essentially of N-lauroyl sarcosine, sodium octyl sulfate, methyl laurate, isopropyl myristate, oleic acid, glyceryl oleate and sodium lauryl sulfoacetate. It has been discovered that certain combination of compounds are excellent penetration enhancers and, as such, can be incorporated in a topical formulation to facilitate administration of diclofenac or a pharmaceutically acceptable salt thereof. The increased penetration enhancement can also lead to a reduction in the total concentration of skin irritants in the formulation.

Owner:CRESCITA THERAPEUTICS INC

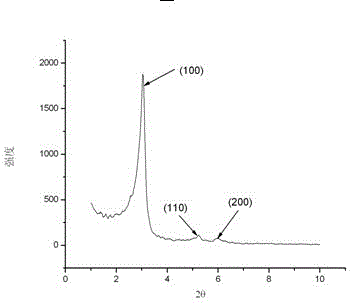

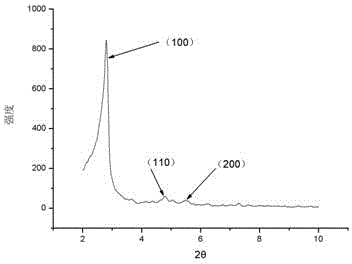

Method for synthesizing highly ordered super-microporous silicon dioxide

InactiveCN103058206ALow costMild reaction conditionsSilicaActive agentDecyltrimethylammonium bromide

The invention relates to a method for synthesizing highly ordered super-microporous silicon dioxide. The method includes steps: firstly, mixing decyltrimethylammonium bromide, sodium octyl sulfate, sodium silicate and water according to the molar ratio of 1:0.1-0.4:1.5:800, and stirring for 0.5 hour at room temperature; secondly, adjusting hydrogen ion concentration (PH) to range from 9 to 10 by using sulfuric acid solution with concentration of 2mol / L; and thirdly, heating the mixed liquor for 72 hours by using water with temperature of 80 DEG C, filtering, washing, drying in air, and roasting at temperature between 530 DEG C and 560 DEG C to obtain the product. The sodium silicate used in the method uses the decyltrimethylammonium bromide as a short chain positive ion surface active agent and the sodium octyl sulfate as a short chain negative ion surface active agent. The method is low in cost, temperate in reacting condition and high in order of product pore channels, and is a novel method provided for future large-scale development and utilization of the highly ordered super-microporous silicon dioxide.

Owner:TAISHAN MEDICAL UNIV

Method of roughening rolled copper or copper alloy foil

ActiveUS8252166B2Reduced craterHigh peel strengthElectrolytic coatingsPrinted circuit aspectsSulfateTin plating

A rolled copper or copper alloy foil having a roughened surface formed of fine copper particles is obtained by subjecting a rolled foil to roughening plating with a plating bath containing copper sulfate (Cu equivalent of 1 to 50 g / L), 1 to 150 g / L of sulfuric acid, and one or more additives selected among sodium octyl sulfate, sodium decyl sulfate, and sodium dodecyl sulfate under the conditions of temperature of 20 to 50° C. and current density of 10 to 100 A / dm2. The foil has reduced craters, which are defects unique to rolled foils having a roughened surface, has high strength, adhesive strength with the resin layer, acid resistance and anti-tin plating solution properties, high peel strength, favorable etching properties and gloss level, and is suitable for producing a flexible printed wiring board capable of bearing a fine wiring pattern. A method of roughening the rolled foil is also provided.

Owner:JX NIPPON MINING & METALS CORP

Anti-rust metal paint

The invention discloses an anti-rust metal paint prepared from the following raw materials in parts by weight: 5-9 parts of copper sulfate, 33-53 parts of deionized water, 6-12 parts of polyimide, 7-12 parts of manganese sulfate, 10-20 parts of sodium octyl sulfate, 5-10 parts of siloxane, 12-35 parts of epoxy resin E20, 6-10 parts of attapulgite clay, 6-9 parts of sodium phosphate, 20-30 parts of melamine formaldehyde resin, 8-16 parts of maleic anhydride, 7-14 parts of zinc cyanurate, 6-10 parts of zinc oxide, 3-5 parts of diatom mud, 7-15 parts of a wax liquid, 6-12 parts of an aluminum powder, and 3-9 parts of phenolic resin. The invention provides the anti-rust metal paint having the advantages of good flexibility, excellent adhesive power, excellent high-temperature resistance, excellent rust protection and excellent corrosion resistance, and absorbing ultraviolet light.

Owner:QINGDAO JISHUNLONG TRADING

Metallic paint and preparation method thereof

The invention discloses metallic paint and a preparation method thereof and relates to the technical field of chemical industry. The metallic paint comprises the following components: 45-55 percent of hydroxylated acrylic resin, 1-1.5 percent of sodium octyl sulfate, 12-15 percent of dibutyl maleate, 12-15 percent of sodium hydroxide, 4-7 percent of copper sulfate, 4-6 percent of copper powder, 0.3-0.5 percent of a modified polysiloxane flatting agent and water in balance amount. The metallic paint is good in levelling property, non-poisonous, free of abnormal taste and is suitable for surface repairing of automobiles, motorcycles and the like.

Owner:DRAGON FISH PAINT

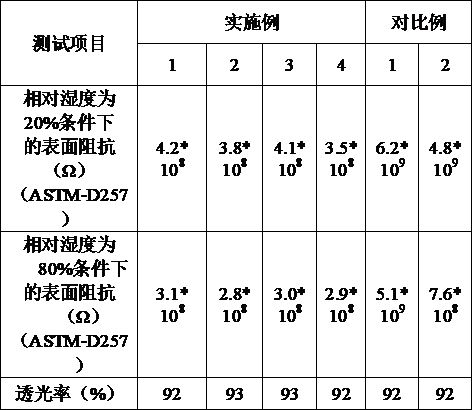

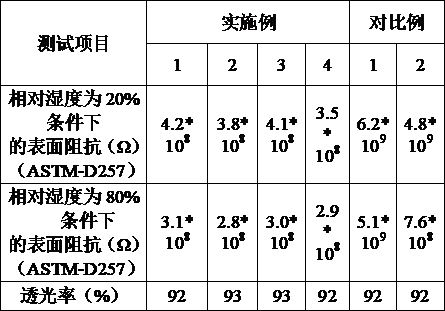

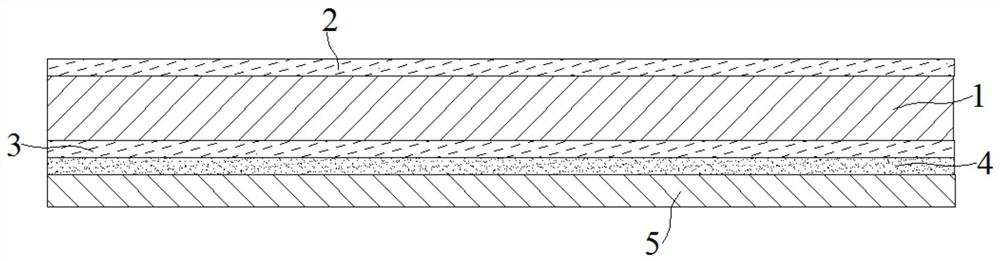

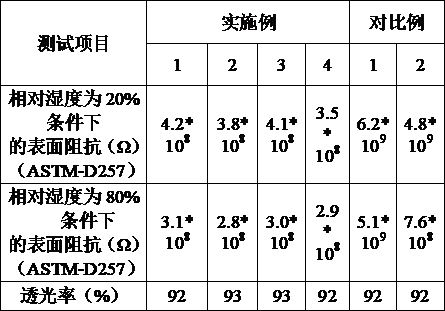

Preparation process for anti-static film used for electronic products

ActiveCN111978582AReduce the chance of injurySmall change in surface resistancePolyurea/polyurethane coatingsElectrically-conductive paintsMethylanilinePolyvinyl alcohol

The invention discloses a preparation process for an anti-static film used for electronic products. The preparation process comprises the following steps: step I, mixing and evenly stirring 100 partsof polyurethane resin, 40-60 parts of polyvinyl alcohol, 2-4 parts of sodium octyl sulfate, 1-3 parts of sodium 3-(N-ethyl-3-methylanilino)propanesulfonate, 8-12 parts of dioctyl terephthalate, 40-60parts of n-butyl alcohol, 20-30 parts of isobutyl acetate, 0.5-1 part of castor oil polyoxyethylene ether, 0.3-0.8 part of triethylenetetramine, 0.5-1.5 parts of silane coupling agent, 0.6-2 parts ofantioxidant and 0.4-1 part of leveling agent to obtain a coating solution; and step II, uniformly applying the coating solution obtained in step I onto a substrate layer (1) through coating, and performing baking and drying to obtain the anti-static film. Not only is the anti-static performance of the anti-static film prepared by the preparation process improved, but also the change of the surfaceresistance of the anti-static film is almost very small, and the anti-static performance is stable under the condition that the change of the anti-static performance is relatively large under the influence of environment humidity, and accordingly, the anti-static film is suitable for the complex electronic product process flow and climate.

Owner:ZHEJIANG OUREN NEW MATERIALS CO LTD

Preparation method of water-based metallic paint

The invention discloses a preparation method of a water-based metallic paint. The water-based metallic paint is prepared from the following raw materials in parts by weight: 20 to 30 parts of sodium octyl sulfate, 4 to 10 parts of stearin-based glycine betaine, 10 to 20 parts of dibutyl maleate, 20 to 30 parts of cresol sulfonic acid, 10 to 15 parts of sodium hydroxide, 20 to 30 parts of potassium sulphate, 4 to 10 parts of sodium phosphate, 4 to 10 parts of copper sulfate, 3 to 5 parts of copper powder, and 30 to 40 parts of water. The water-based metallic paint provided by the invention is non-toxic, free from extraneous odor and non-combustible, the solid content is larger than or equal to 50 percent, the viscosity is 20 to 34s, the adhesion is 1 grade, the fineness is 40 micrometers, and the surface drying time is 10 minutes; after forming a film, the water-based metallic paint has the hardness of 0.3, and the impact strength being larger than or equal to 50kg / cm<2>, and is safe and non-toxic in components, and environmental-friendly and healthy.

Owner:无锡市华东电力设备有限公司

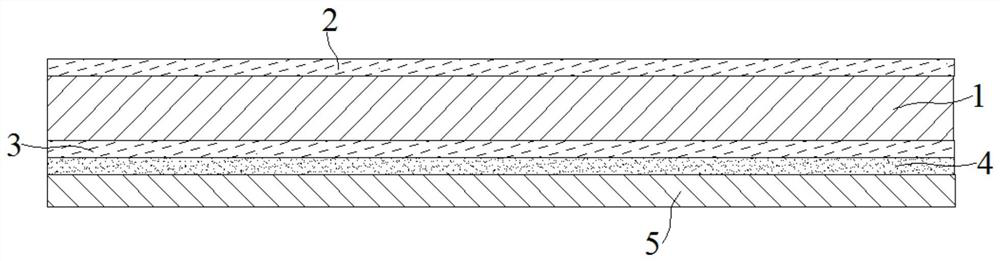

Solvent-resistant antistatic film

ActiveCN111978879ASmall change in surface resistanceReduce the chance of injuryOther chemical processesFilm/foil adhesive primer layersMethylanilinePolymer science

The invention discloses a solvent-resistant antistatic film. The film comprises a substrate layer, a first antistatic coating and a second antistatic coating, wherein the first antistatic coating andthe second antistatic coating are respectively arranged on an upper surface and a lower surface of the substrate layer, and a pressure-sensitive adhesive layer is located between a release layer and the second antistatic coating; the first antistatic coating and the second antistatic coating are obtained by drying a coating liquid, and the coating liquid consists of the following components in parts by weight: polyurethane resin, polyvinyl alcohol, sodium octyl sulfate, N-ethyl-N-(3-sulfopropyl)-3-methylaniline sodium salt, dioctyl terephthalate, n-butyl alcohol, isobutyl acetate, castor oil polyoxyethylene ether, triethylenetetramine, a silane coupling agent, antioxidant and a leveling agent. According to the invention, not only is antistatic property improved, but also the solvent-resistant antistatic film has little surface resistance change and stable antistatic property under a condition that the environmental humidity shadow change is large, so that the solvent-resistant antistatic film is suitable for complex electronic product process flow and climate, and greatly reduces probability of electronic product damage.

Owner:ZHEJIANG OUREN NEW MATERIALS CO LTD

Topical formulation

InactiveUS20100029769A1Improve throughputOrganic active ingredientsBiocideSodium acetateSODIUM LAURYL SULFOACETATE

There is described a topical formulation. The topical formulation comprises: (i) diclofenac or a pharmaceutically acceptable salt thereof, (ii) a first compound, and (iii) a second compound. The first compound and second compound are different, and each is selected from the group consisting essentially of N-lauroyl sarcosine, sodium octyl sulfate, methyl laurate, isopropyl myristate, oleic acid, glyceryl oleate and sodium lauryl sulfoacetate. It has been discovered that certain combination of compounds are excellent penetration enhancers and, as such, can be incorporated in a topical formulation to facilitate administration of diclofenac or a pharmaceutically acceptable salt thereof. The increased penetration enhancement can also lead to a reduction in the total concentration of skin irritants in the formulation.

Owner:CRESCITA THERAPEUTICS INC

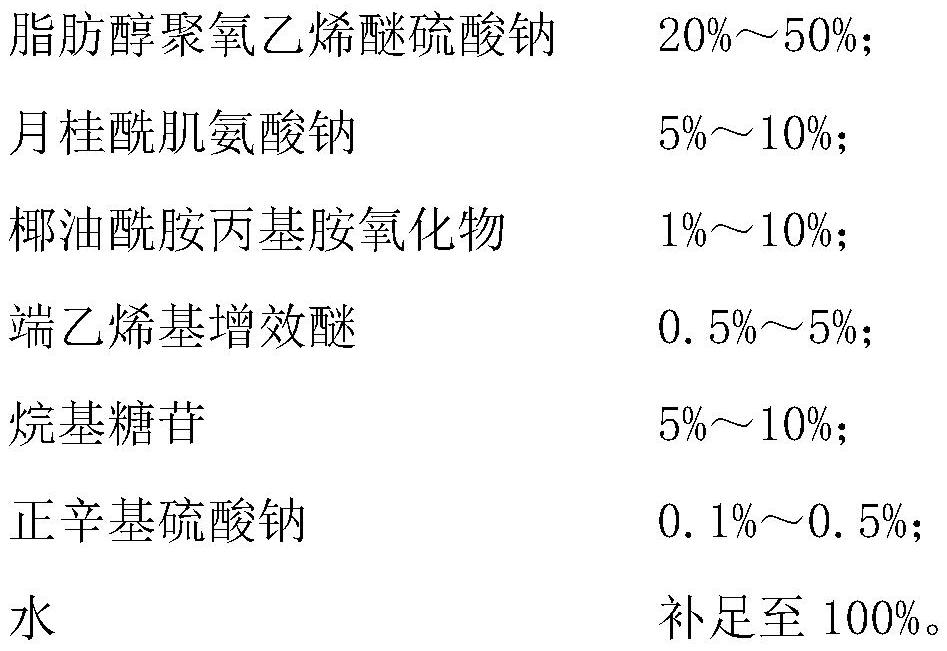

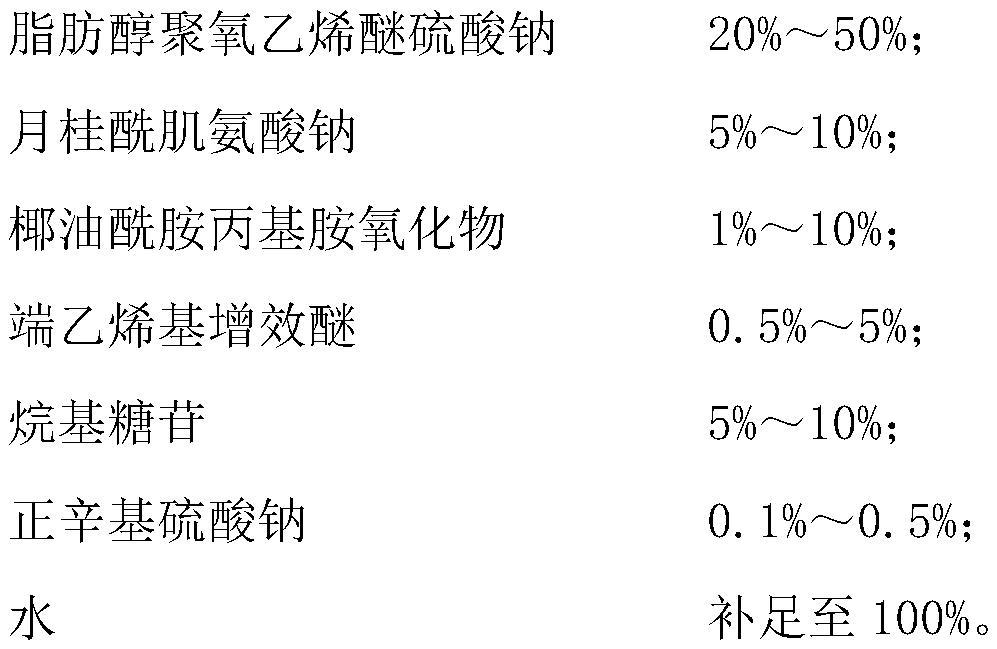

Synergistic low-foam trifluoro bentazone water aqua aid and preparation process thereof

InactiveCN111869663AImprove general performanceImprove weed control effectBiocideAnimal repellantsSarcosineDioxyethylene Ether

The invention provides a synergistic low-foam trifluoro bentazone water aqua aid which comprises sodium alcohol ether sulphate, sodium lauroyl sarcosine, cocamidopropylamine oxide, alkyl glycoside, vinyl-terminated synergistic ether and sodium n-octyl sulphate according to a weight ratio of 20-50 : 5-10 : 1-10 : 5-10 : 0.5-5 : 0.1-0.5. The invention has the beneficial effects that the pesticide water aqua can truly achieve the purposes of heat resistance, cold resistance, biodegradability, high quality, high efficiency and environmental protection.

Owner:南京拓凯新材料科技有限公司

Cyanide-free gold plating solution for loudspeaker basin stand

PendingCN114351129AImprove wear resistanceLiquid/solution decomposition chemical coatingPhosphorous acidMeth-

The invention discloses a cyanide-free gold plating solution for a loudspeaker basin stand. The cyanide-free gold plating solution comprises the following raw materials: tetrachloro-alloyed acid, a composite complexing agent, potassium tartrate, sodium methylallyl sulfonate, sodium n-octyl sulfate, a reaction accelerator, a stabilizer, polyacrylamide, a corrosion inhibitor, polyethylene glycol, ethylenediamine and a composite reducing agent, the composite complexing agent is a mixture of 2-amino-5-sulfydryl-1, 3, 4-thiazole, sodium ethylenediamine tetramethylenephosphonate and triammonium citrate; the composite reducing agent is a mixture of sodium hypophosphite, hydroxylamine sulfate, sodium gluconate and ascorbic acid. The cyanide-free gold plating solution for the loudspeaker basin stand is good in stability and high in plating speed, and an obtained plating layer is uniform in thickness, good in brightness and excellent in corrosion resistance, wear resistance and discoloration resistance.

Owner:GANZHOU KINGYUNG TECH CO LTD

Novel electroplating solution

The invention discloses a novel electroplating solution. The novel electroplating solution is prepared from the following components: nickel sulfate, nickel chloride, sodium chloride, magnesium sulfate, boric acid, sodium sulfate, sodium citrate, sodium carboxymethyl cellulose (CMC), ethylene glycol, sodium octyl sulfate and water. According to the novel electroplating solution provided by the invention, a more dense and compact dark nickel plating layer can be obtained and a bonding capability of the plating layer and a plated metal surface is strong; phenomenon of peeling, falling and pinholes and the like do not occur.

Owner:CHENGDU LIANLIDA HARDWARE PROD

Method for preparing composite hydrate accelerant

Owner:溧阳常大技术转移中心有限公司

Long-acting metal corrosion inhibitor

A long-acting metal corrosion inhibitor disclosed in the invention contains water-containing silicate mineral as a main component, and also comprises 15-20 parts of sodium octyl sulfate, 5-15 parts of triethylamine, 15-20 parts of sodium hydroxide and 5-10 parts of dibutyl maleate. The long-acting metal corrosion inhibitor has better effect than metal corrosion inhibitors in the prior art by adding sodium octyl sulfate, triethylamine, sodium hydroxide and dibutyl maleate.

Owner:SHENYANG CHUANGDA TECH TRADE MARKET

Water-based environment-friendly carbon deposit cleaning agent

InactiveCN112342093AEasy to cleanOrganic detergent compounding agentsNon-ionic surface-active compoundsDioxyethylene EtherCarbon deposit

The invention relates to a water-based environment-friendly carbon deposit cleaning agent which has a special effect of removing carbon deposit generated by a powder coating nozzle, a range hood, an automobile engine and the like at high temperature. The cleaning agent comprises the following components in percentage by weight: 3-10% of sodium isooctyl sulfate; 2-8% of sec-octyl alcohol polyoxyethylene ether; 0.1-0.5% of limonene; 0.5 to 5% of triethanolamine; 3 to 12% of 2, 4-dimethyl isoprene glycol; 0.1 to 0.5% of sodium citrate; and the balance deionized water.

Owner:NAFINE CHEMICAL INDUSTRY GROUP CO LTD

Solvent-resistant antistatic film

ActiveCN111978879BSmall change in surface resistanceReduce the chance of injuryOther chemical processesFilm/foil adhesive primer layersMethylanilinePolymer science

The invention discloses a solvent-resistant antistatic film, which comprises a substrate layer, a first antistatic coating and a second antistatic coating, and the first antistatic coating and the second antistatic coating are respectively located on the base The upper surface and the lower surface of the material layer, a pressure-sensitive adhesive layer is located between the release layer and the second antistatic coating; the first antistatic coating and the second antistatic coating are dried by the coating liquid Obtained, this coating solution is made up of the following components by weight: polyurethane resin, polyvinyl alcohol, sodium octyl sulfate, N-ethyl-N-(3-sulfopropyl)-3-methylaniline sodium salt, p- Dioctyl phthalate, n-butanol, isobutyl acetate, castor oil polyoxyethylene ether, triethylenetetramine, silane coupling agent, antioxidant, leveling agent. The invention not only improves the antistatic performance, but also enables the solvent-resistant antistatic film to have a small change in surface resistance and stable antistatic performance under the condition of large changes in environmental humidity, so that it is suitable for complex electronic product processes and climates. Greatly reduces the chance of damage to electronic products.

Owner:ZHEJIANG OUREN NEW MATERIALS CO LTD

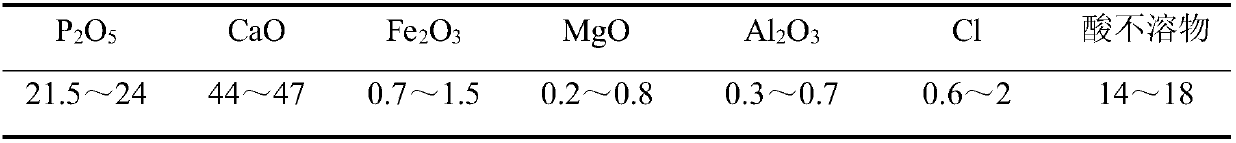

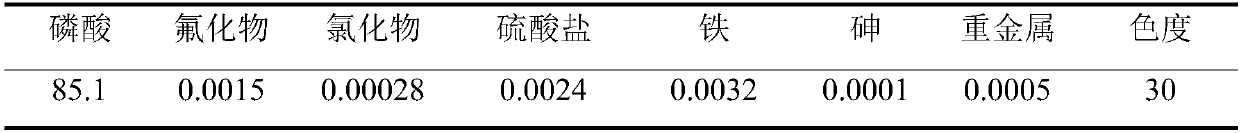

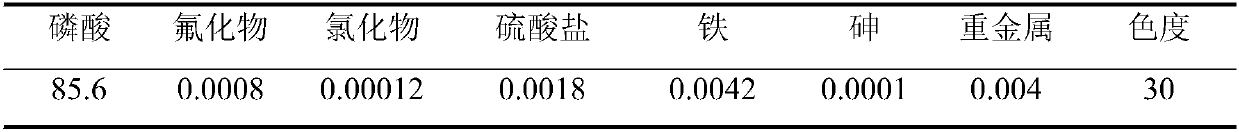

A kind of extraction agent and extraction method of industrial phosphoric acid produced by hydrochloric acid method

ActiveCN106348273BIncrease repulsionSimplify preprocessing stepsPhosphorus compoundsPhosphoric Acid EstersO-Phosphoric Acid

The invention discloses an extraction agent for preparing industrial phosphoric acid through a hydrochloric acid method and an extraction method thereof. The extraction agent comprises, by mass, 10-50% of one or two of tributyl phosphate or tributoxy ethyl phosphate, 15-40% of one or multiple of n-butyl alcohol, isooctanol, cyclohexanol, isopropanol and isoamylol, 10-30% of one or two of n-butyl ether, isopropyl ether and diisopropyl ether, 5-30% of one or multiple of high-carbon ketone, aliphatic amine or quaternary ammonium salt and 1-10% of one or multiple of oil-based polyoxyethylene ether phosphate, octyl sodium sulfate, alpha-alkenyl sodium sulfonate, sodium lignin sulfonate, stearyl sulfo succinamide disodium and lauryl ammonium sulfate. The extraction agent is wide in application condition, low in solvent loss and convenient to recycle, and extraction rate can reach higher than 80%.

Owner:HUBEI SANNING CHEM

Electric plating liquid

The invention discloses electric plating liquid, which is prepared from the following ingredients including nickel sulfate, nickel chloride, boracic acid, ammonia sodium sulfonate, sodium citrate, CMC(sodium carboxymethyl cellulose), glycol, sodium octyl sulfate and water. By using the electric plating liquid, a tighter and more compact plating layer can be obtained; the bonding capability of theplating layer with the surface of the plated metal is high; phenomena such as peeling, falling, pinhole cannot occur.

Owner:CHENGDU LIANLIDA HARDWARE PROD

Environment-friendly A-type foam fire extinguishing agent

The invention relates to an environment-friendly A-type foam fire extinguishing agent which is prepared from the following components in parts by weight: 19-30 parts of sodium octyl sulfate, 5-20 parts of C<8-10>alpha-olefin sulfonate, 20-50 parts of ethylene glycol monobutyl ether, 1-5 parts of gellan gum, 0.5-2 parts of dioctyl sodium sulfosuccinate, 0.5-2 parts of S-carboxyethyl mercaptobutanedioic acid, 0.5-2 parts of lauroyl sarcosine and 20-50 parts of water. The environment-friendly A-type foam fire extinguishing agent provided by the invention has excellent fire extinguishing property and low toxicity property.

Owner:ANHUI TIANYUAN FIRE PROTECTION TECH

A kind of neutral environment-friendly water system fire extinguishing agent and preparation method thereof

The invention relates to a neutral environmentally-friendly water-based fire extinguishing agent and a preparation method thereof. The neutral environmentally-friendly water-based fire extinguishing agent comprises water, a first fire extinguishing component, a second fire extinguishing component, citric acid and a water-soluble surfactant component, wherein the first fire extinguishing component comprises two or more of such inorganic compounds as ammonium dihydrogen phosphate, urea, potassium carbonate and ammonium monohydric phosphate; the second fire extinguishing component comprises one or more of potassium sulfate, potassium bicarbonate, sodium phosphate, organic acid and potassium acetate; and the water-soluble surfactant component comprises two or more of sodium lauryl sulfate, hexadecyl trimethyl ammonium chloride, perfluorooctane surfapropyl betaine, sodium octyl sulfate and sodium decyl sulfate. The preparation method comprises the following steps: adding water into a stirring machine, and sequentially adding all the components while stirring, so as to obtain a product finally. The finally prepared neutral environmentally-friendly water-based fire extinguishing agent can be applied to A-class, B-class and F-class fire disasters, and has the advantages that the corrosion problem can be solved without adding an antirust agent; the low-temperature (minus 25 DEG C) problem can be solved without adding an anti-freezing agent; and the environmentally-friendly effect can be achieved.

Owner:ANHUA FIRE NEW MATERIAL TECH (JIANGSU) CO LTD

Method of Roughening Rolled Copper or Copper Alloy Foil

ActiveUS20120012463A1Reduced craterHigh peel strengthElectrolytic coatingsPrinted circuit aspectsTin platingCopper sulfate

A rolled copper or copper alloy foil having a roughened surface formed of fine copper particles is obtained by subjecting a rolled foil to roughening plating with a plating bath containing copper sulfate (Cu equivalent of 1 to 50 g / L), 1 to 150 g / L of sulfuric acid, and one or more additives selected among sodium octyl sulfate, sodium decyl sulfate, and sodium dodecyl sulfate under the conditions of temperature of 20 to 50° C. and current density of 10 to 100 A / dm2. The foil has reduced craters, which are defects unique to rolled foils having a roughened surface, has high strength, adhesive strength with the resin layer, acid resistance and anti-tin plating solution properties, high peel strength, favorable etching properties and gloss level, and is suitable for producing a flexible printed wiring board capable of bearing a fine wiring pattern. A method of roughening the rolled foil is also provided.

Owner:JX NIPPON MINING & METALS CORP

Inorganic phase change material with phase change temperature of 60 DEG C and preparation method of inorganic phase change material

InactiveCN108753263AImprove performanceLarge latent heat of phase changeHeat-exchange elementsAluminum ammonium sulfateSodium carbonate anhydrous

The invention discloses a preparation method of an inorganic phase change material with a phase change temperature of 60 DEG C. The method comprises the steps of mixing a certain amount of magnesium sulfate heptahydrate and a certain amount of sodium sulfafe decahydrate in a preparation dish, adding a certain amount of potassium sulfate and aluminum potassium sulfate dodecahydrate for uniform mixing at a certain temperature, adding a certain amount of anhydrous sodium carbonate, sodium allysulfonate and aluminum ammonium sulfate for uniform mixing a certain temperature, adding a certain amountof sodium octyl sulfate, aluminum ammonium sulfate and potassium nitroferrocyanide for uniform mixing at a certain temperature, and adding a certain amount of water for uniform stirring to form a mixture, namely the inorganic phase change material with the phase change temperature of 60 DEG C. The method has the benefits that the inorganic phase change material with the phase change temperature of 60 DEG C has the advantages of stable performance, high latent heat of phase change, no toxicity or corrosion and the like.

Owner:北京电管家科技股份有限公司

Plating solution

The invention relates to a plating solution, made from, by weight, 1-6 parts of potassium sodium tartrate, 4-11 parts of thiohydantoin, 15-20 parts of sodium octyl sulfate, and 40-50 parts of nickel sulfate solution. The plating solution has stable composition; a plating layer made with the plating solution has good heat resistance, rarely experiences spot corrosion and has long life.

Owner:CHENGDU LIANLIDA HARDWARE PROD

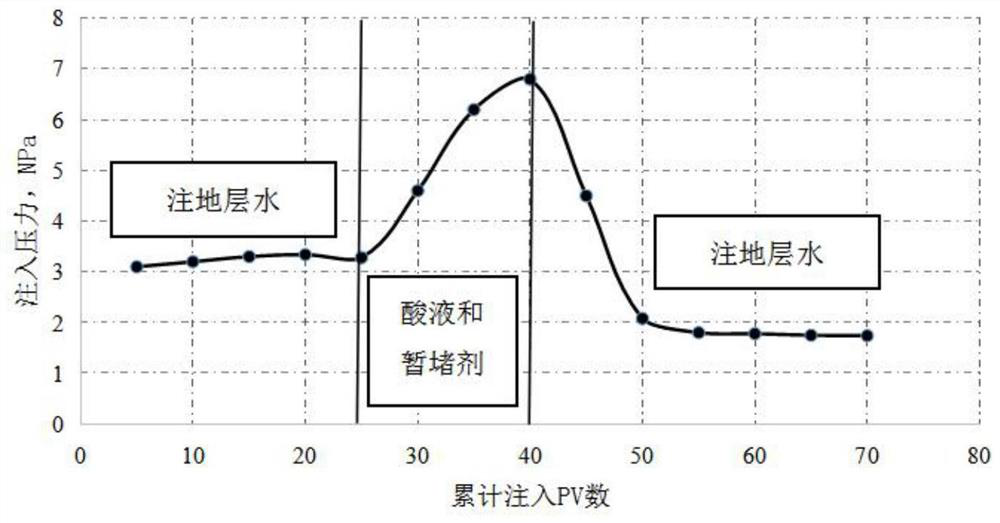

A salinity-sensitive shunt temporary plugging agent and its preparation method and application

ActiveCN111100617BDissolve fastImproved water absorption profileDrilling compositionSealing/packingEnvironmental engineeringAlkene

The invention belongs to the technical field of reservoir diversion acidification construction, and in particular relates to a salinity-sensitive diversion temporary plugging agent and its preparation method and application. The salinity-sensitive shunting temporary plugging agent of the present invention is composed of the following raw materials: 20.0%-25.0% olefin sulfonic acid, 10.0%-20.0% octyl sodium sulfate, 3.0%-5.0% dodecyl sodium sulfate , 20.0%‑25.0% methanol, the balance being water. The salinity-sensitive diversion temporary plugging agent of the present invention is used in the construction process of reservoir diversion acidification. During the acidification process, the salinity-sensitive diversion temporary plugging agent will reduce the concentration of calcium ions produced during the reaction between the acid liquid and the formation. When it rises to more than 2%, 5-200 micron micelles are formed, which can block the high-permeability layer of the formation, promote the acid solution to turn to the low-permeability layer for transformation, and improve the water absorption profile; after the acidification is completed and the water injection is resumed, the formed The micelles can be quickly dissolved in water, and finally achieve the purpose of reducing blood pressure and increasing production.

Owner:PETROCHINA CO LTD

Neutral bottle plug cleaning agent and preparation method thereof

InactiveCN111304024ADoes not damage the molecular structureEfficient removalNon-ionic surface-active compoundsDetergent compounding agentsDioxyethylene EtherCleansing Agents

The invention discloses a neutral bottle plug cleaning agent and a preparation method thereof. The neutral bottle plug cleaning agent comprises the following components: fatty alcohol polyoxyethyleneether sodium sulfate, sodium isodecyl sulfosuccinate, sodium propoxyhydroxypropyl sulfonate, sodium isooctyl sulphate, alkyl glycoside, fatty alcohol-polyoxyethylene ether, sodium citrate and water. The preparation method comprises the following steps: adding the components into a part of water, stirring, adding the remaining water, and stirring to obtain the neutral bottle plug cleaning agent. Bymeans of the mode, the molecular structure of the surface of the bottle plug cannot be damaged, residual oily demolding agent and separant on the surface of the bottle plug can be effectively removed, and the bottle plug cleaning agent has the advantages of being non-toxic, tasteless, phosphorus-free, pollution-free, neutral, easy to rinse and the like.

Owner:郑州孚松科技有限公司

Low-alkali and low-foam deoiling agent at room temperature

The present invention discloses a formula of a low-alkali and low-foam deoiling agent at a room temperature. The low-alkali and low-foam deoiling agent comprises, by weight, 25-30 parts of sodium carbonate, 8-10 parts of sodium tripolyphosphate, 1-7 parts of sodium dodecylbenzene sulfonate, 13-16 parts of sodium octyl sulfate, 50-68 parts of an amphoteric activator, and 0.1-0.5 part of a defoamer. According to the present invention, the sodium octyl sulfate and the amphoteric activator are adopted, such that the low-alkali and low-foam deoiling agent has the deoiling effect at the room temperature; and the defoamer is added, such that the low-alkali and low-foam deoiling agent has characteristics of low alkali, low foam and environmental protection, and the production cost is reduced.

Owner:NANJING HENGAN RESIN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com