Solvent-resistant antistatic film

An antistatic film and antistatic technology, applied in the direction of adhesives, conductive coatings, film/sheet release coatings, etc., can solve the problems of unstable antistatic performance, uncertain product risk, and large humidity change range, etc., to achieve antistatic Stable electrostatic performance, reduced chance of damage, small change in surface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

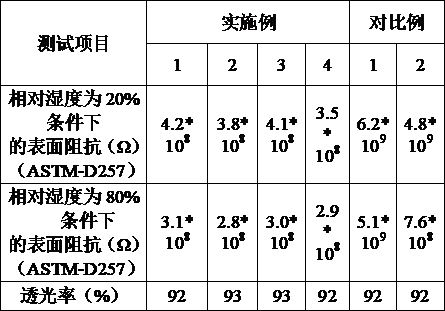

Embodiment 1~4

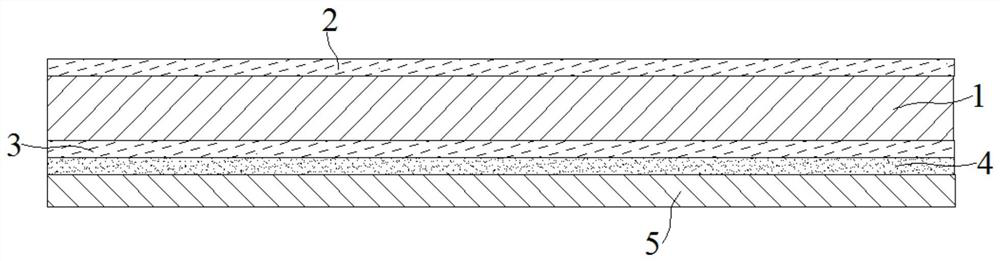

[0031] Embodiment 1~4: a kind of solvent-resistant type antistatic film, comprise substrate layer 1, the first antistatic coating 2 and the second antistatic coating 3, described first antistatic coating 2 and second antistatic coating The electrostatic coating 3 is located on the upper surface and the lower surface of the substrate layer 1 respectively, and a pressure-sensitive adhesive layer 4 is located between the release layer 5 and the second antistatic coating 3, and the pressure-sensitive adhesive layer 4 is located on the second antistatic layer. The surface of the electrostatic coating 3 opposite to the substrate layer 1;

[0032] Both the first antistatic coating 2 and the second antistatic coating 3 are obtained by drying the coating solution, and the coating solution consists of the following components in parts by weight, as shown in Table 1:

[0033] Table 1

[0034] ;

Embodiment 1

[0035] In Example 1, the antioxidant is selected from antioxidant 1010, the above-mentioned leveling agent is selected from leveling agent 440, the above-mentioned substrate layer 1 is a PET layer, the thickness of the above-mentioned substrate layer 1 is 50 μm, and the above-mentioned first antistatic coating 2 and the second antistatic coating 3 both have a thickness of 6 μm.

Embodiment 2

[0036] In Example 2, the antioxidant is selected from antioxidant 1024, the above-mentioned leveling agent is selected from the leveling agent DC57, the above-mentioned substrate layer 1 is a TPU layer, the thickness of the above-mentioned substrate layer 1 is 50 μm, and the above-mentioned first antistatic coating 2 and the second antistatic coating 3 both have a thickness of 6 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com