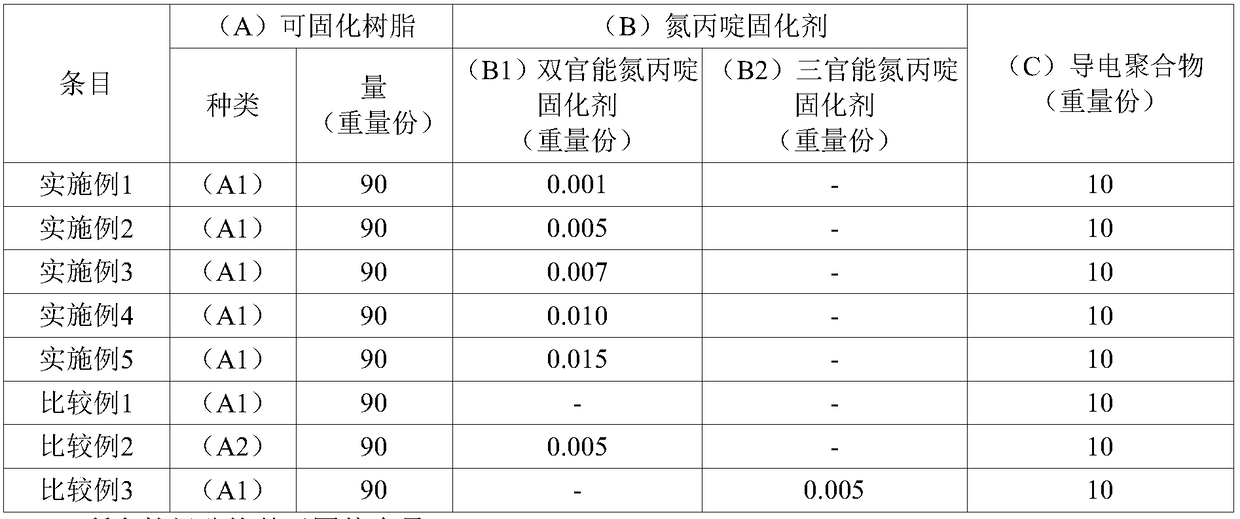

Composition for static dissipative coating layer, polarizing plate and optical display apparatus

A technology of electrostatic dissipation and composition, applied in the direction of coating, optics, conductive coatings, etc., can solve the problems of performance degradation, film can not be used effectively, insufficient optical properties such as transparency and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] In the preparation of prepolymers, tin compounds, such as tin salts of carboxylic acids, such as dibutyltin dilaurate, or amine compounds, such as dimethylcyclohexylamine or triethylenediamine, can be further included as catalysts to promote Formation of urethane bonds. In the preparation of the prepolymer, diol (such as aliphatic diol), aminoalcohol, diamine, hydrazine, hydrazide or a mixture thereof may be further included as a chain extender for extending the chain of the prepolymer. Preparation of the prepolymer may be performed at 50°C to 200°C for 30 minutes to 10 hours. Within this range, prepolymers can be produced in high yield.

[0067] Then, by polymerizing a (meth)acrylic monomer containing no carboxylic acid group with the prepared prepolymer, followed by polymerization with a (meth)acrylic monomer containing a carboxylic acid group, a Polyurethane (meth)acrylate with acid groups. The (meth)acrylic monomer not containing a carboxylic acid group may inclu...

preparation example 1

[0139] Preparation Example 1: Preparation of Curable Resin

[0140] 200 g of polycaprolactone diol (weight average molecular weight: 2,000 g / mol, Daicel Chemical Industries, Ltd.) was placed in a 1 L reactor purged with nitrogen. Then, 105 g of methylene diphenyl diisocyanate (MDI, BASF) and 0.5 g of dibutyltin dilaurate (DBTDL) (S, Soken Co., Ltd.) were further added thereto. In the reactor, the resulting mixture was stirred at 90° C. for 30 minutes. While stirring the mixture at a constant rate, 27 g of dimethylolpropionic acid (Pestorp Co., Ltd.) was added thereto to provide ions, and 110 g of N-methyl-2-pyrrolidine (NMP, Samchun Chemicals Co., Ltd.) to dissolve dimethylolpropionic acid. Then, the resulting mixture was left in a reactor at 92° C. for 5 hours.

[0141] The prepolymer obtained from the reactor was cooled to 75° C. and 264 g of methyl methacrylate (Aldrich GmbH) were added to the prepolymer. The resulting mixture was stirred at 75°C for 15 minutes and cool...

preparation example 2

[0142] Preparation Example 2: Preparation of Curable Resin

[0143] 200 g of polycaprolactone diol (weight average molecular weight: 2,000 g / mol, Daicel Chemical Industries, Ltd.) was placed in a 1 L reactor purged with nitrogen. Then, 105 g of methylene diphenyl diisocyanate (MDI, BASF) and 0.5 g of dibutyltin dilaurate (DBTDL) (S, Soken Co., Ltd.) were further added to the reactor. The resulting mixture was stirred at 90° C. for 30 minutes in a reactor. While stirring the mixture at a constant rate, 27 g of dimethylolpropionic acid (Pestorp Co., Ltd.) was added to the reactor to provide ions, and 110 g of N-methyl-2-pyrrolidine (NMP, Samchun Chemicals Co., Ltd.) to dissolve dimethylolpropionic acid. Then, the resulting mixture was left in a reactor at 92° C. for 5 hours.

[0144] The prepolymer obtained from the reactor was cooled to 75° C. and 264 g of methyl methacrylate (Aldrich GmbH) were added to the prepolymer. The resulting mixture was stirred at 75°C for 15 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com