Novel environment-friendly antimony-added alloy bar

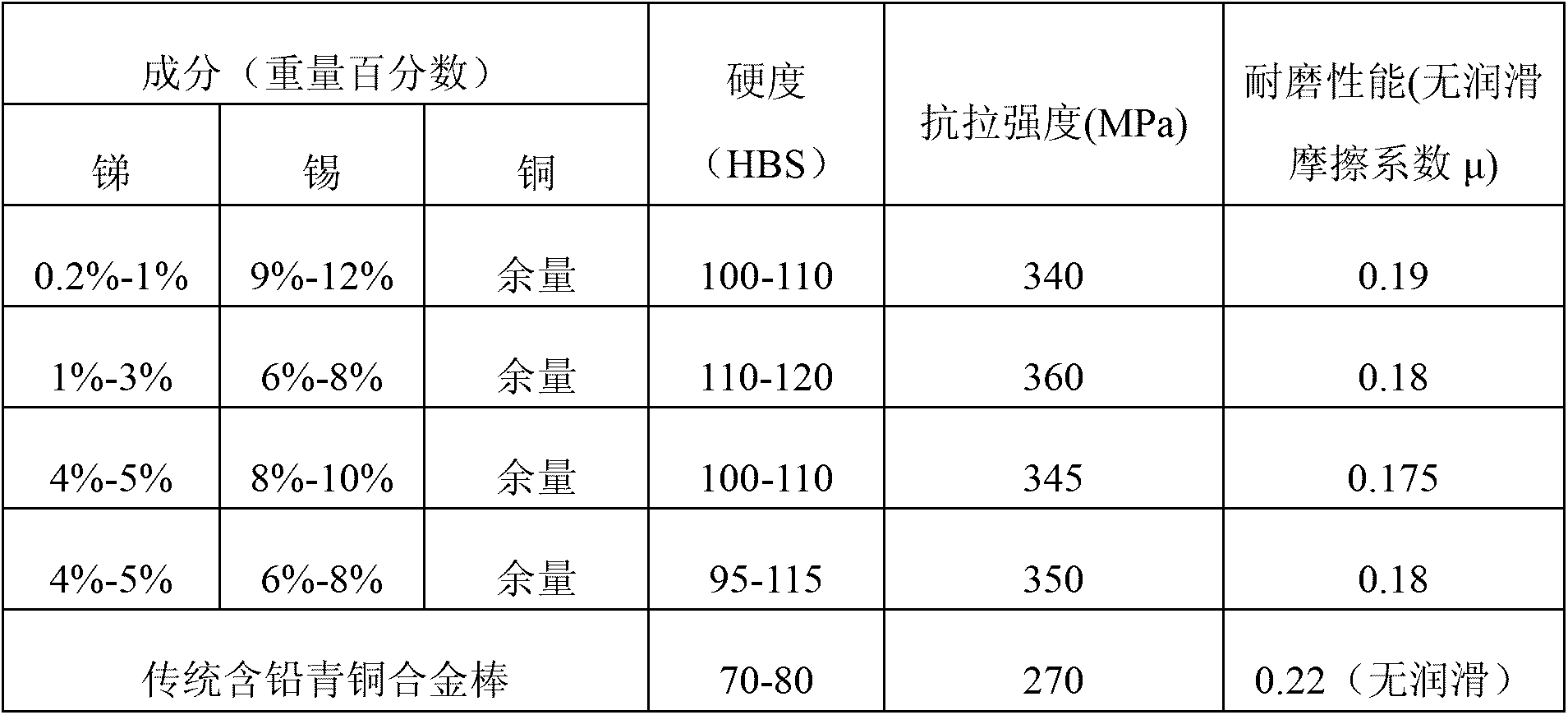

An antimony alloy and alloy rod technology, which is applied in the field of new environmentally friendly antimony-added alloy rods and their preparation, can solve the problems that bronze alloy rods cannot meet requirements, and achieve the effects of improving wear resistance, environmental protection performance, and tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A method for preparing a new environment-friendly antimony-added alloy rod. According to the proportion, 0.2%-5% by weight of antimony, 6%-12% by weight of tin, and the rest of electrolytic copper are placed in a power frequency electric furnace and heated to 1150 degrees. After melting at -1350 degrees, keep it warm to 1100 degrees -1250 degrees. After fully stirring the completely melted alloy liquid with a special graphite tool, it is covered with high-purity flake graphite powder to prevent its oxidation, with a thickness of about 12-25cm. After the holding time is 0.5-2.0 hours, the temperature is raised to 1200-1350 degrees again, and the vibration device of the industrial frequency electric furnace is turned on, and the vibration frequency is 1 time / second. A solid alloy bar with an outer diameter of 50mm-80mm and a length of 2000mm is cast by horizontal continuous casting. One end of the alloy rod is made into a drawn section with a length of 100mm and a diamet...

Embodiment 2

[0066] A method for preparing a new type of environmentally friendly antimony-added alloy rod. According to the proportion, 0.2%-1% by weight of antimony, 9%-12% by weight of tin, and the remaining copper are placed in a power frequency electric furnace and heated to 1300 degrees- After completely melting at 1350 degrees, keep warm to 1250 degrees. After the completely melted alloy liquid is fully stirred with a special graphite tool, it is covered with high-purity flake graphite powder to prevent its oxidation, with a thickness of about 12-15cm. After the heat preservation time is 1-1.5 hours, the temperature is raised to 1300 degrees again, and the vibration device of the industrial frequency electric furnace is turned on, and the vibration frequency is 1 time / second. A solid alloy bar with an outer diameter of 60 mm and a length of 2000 mm was cast by horizontal continuous casting. One end of the alloy rod is made into a drawn section with a length of 100 mm and a diameter...

Embodiment 3

[0069] A preparation method of a new environment-friendly antimony-added alloy rod. According to the proportion, 0.2% by weight of antimony, 9% by weight of tin, and the rest of electrolytic copper, tin, and antimony are placed in a power frequency electric furnace and heated to 1300-1350 After the temperature is completely melted, keep it warm to 1250 degrees. After the completely melted alloy liquid is fully stirred with a special graphite tool, it is covered with high-purity flake graphite powder to prevent its oxidation, with a thickness of about 12-15cm. After the heat preservation time is 1-1.5 hours, the temperature is raised to 1300 degrees again, and the vibration device of the industrial frequency electric furnace is turned on, and the vibration frequency is 1 time / second. A solid alloy bar with an outer diameter of 60 mm and a length of 2000 mm was cast by horizontal continuous casting. One end of the alloy rod is made into a drawn section with a length of 100 mm a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com