Gear carburization thermal treatment tool

A gear and carburizing technology, used in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of large end face distortion, high manufacturing costs, and difficult management, and achieve low manufacturing difficulty, simple installation, and economical improvement. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

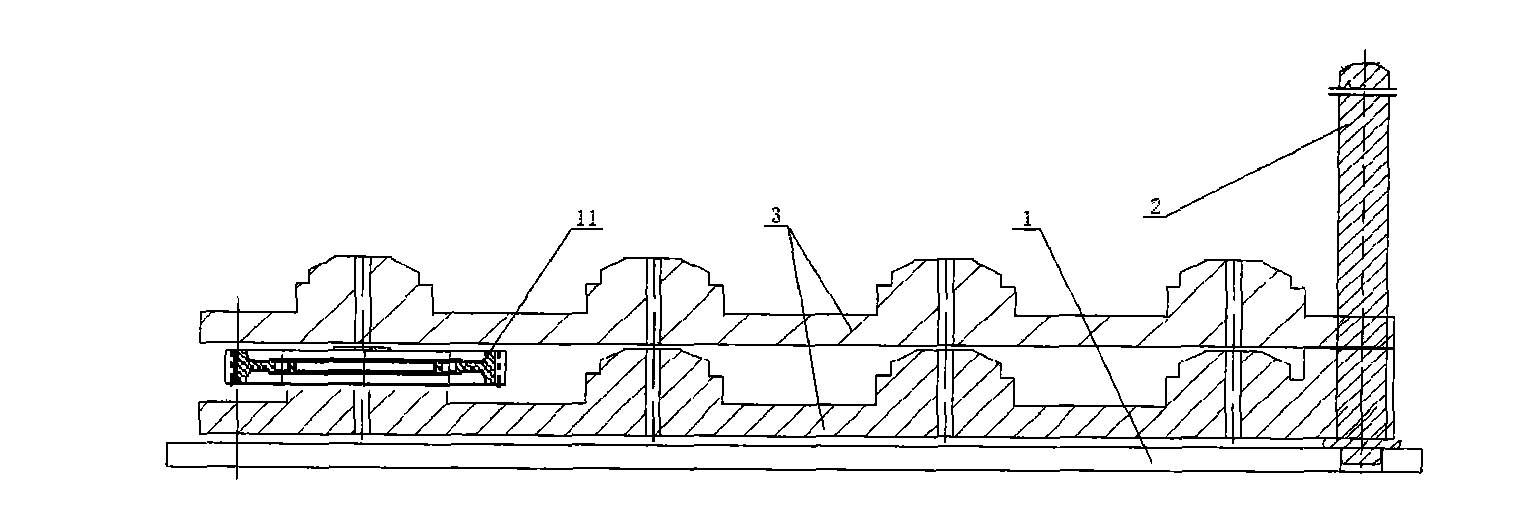

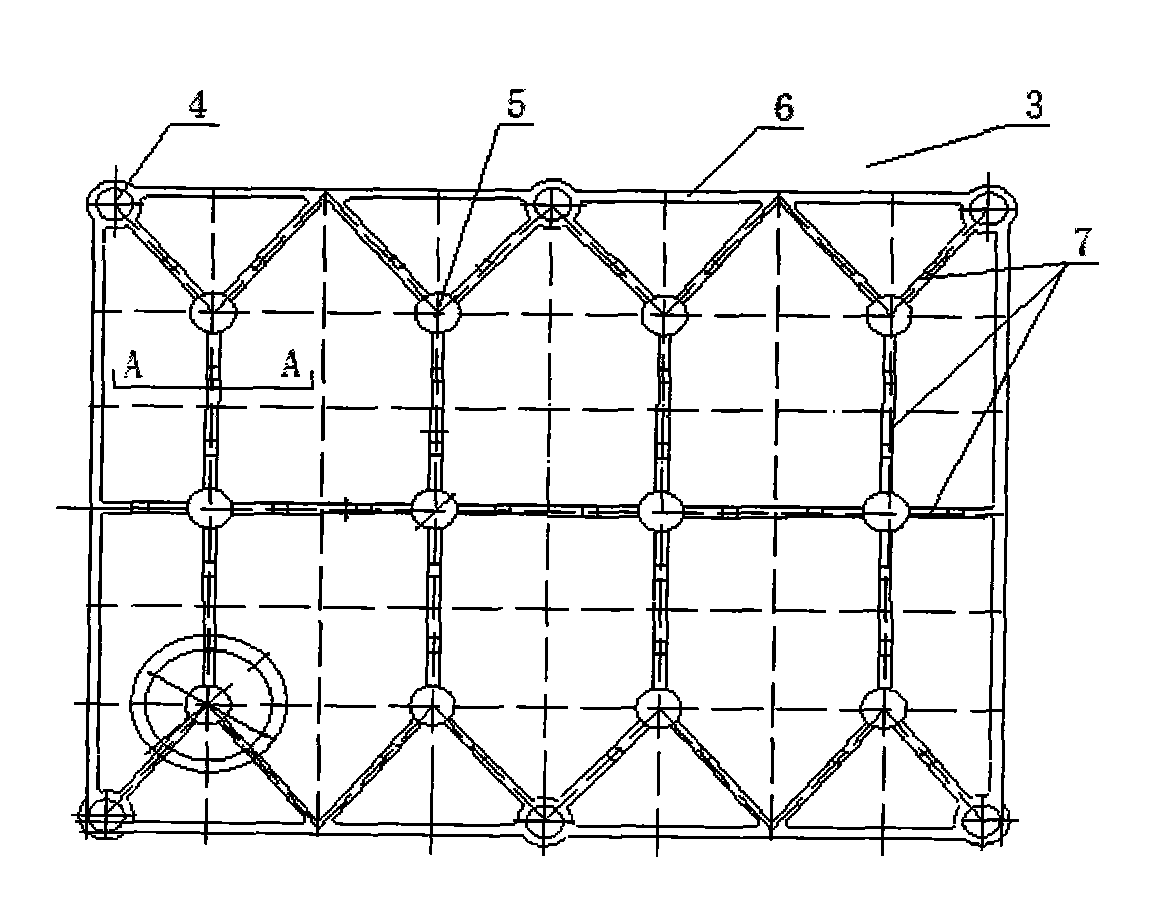

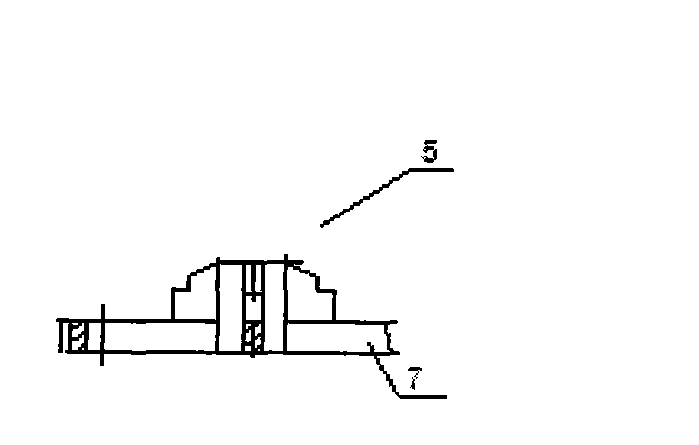

[0016] Depend on Figure 1-Figure 6 It can be seen that the present invention includes a gear support frame 3, the gear support frame 3 is surrounded by a support frame installation hole 4, and a plurality of support columns 5 are uniformly arranged in the middle, and the support columns 5 are connected by support ribs 7, and are close to The boundary of the gear support frame 3 is connected to the frame body frame 6 through the support ribs 7. The support column 5 is provided with a stepped table and the upper end is provided with chamfers. The cylindrical tooling angle mounting hole 9 corresponding to the mounting hole 4, a plurality of rectangular holes 10 are evenly opened on the chassis 1, and the lower end of the cylindrical tooling angle 2 is provided with a circular boss 8 near the end face, and the cylindrical tooling angle 2 The posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com