Novel winding device for crude foil machine

A foil machine, a new type of technology, applied in the electrolysis process, electroforming, etc., can solve the problems of copper foil waste, high manufacturing cost, affecting production efficiency, etc., to ensure the accuracy of secondary clamping, convenient loading and unloading operations, and reduce manufacturing costs. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

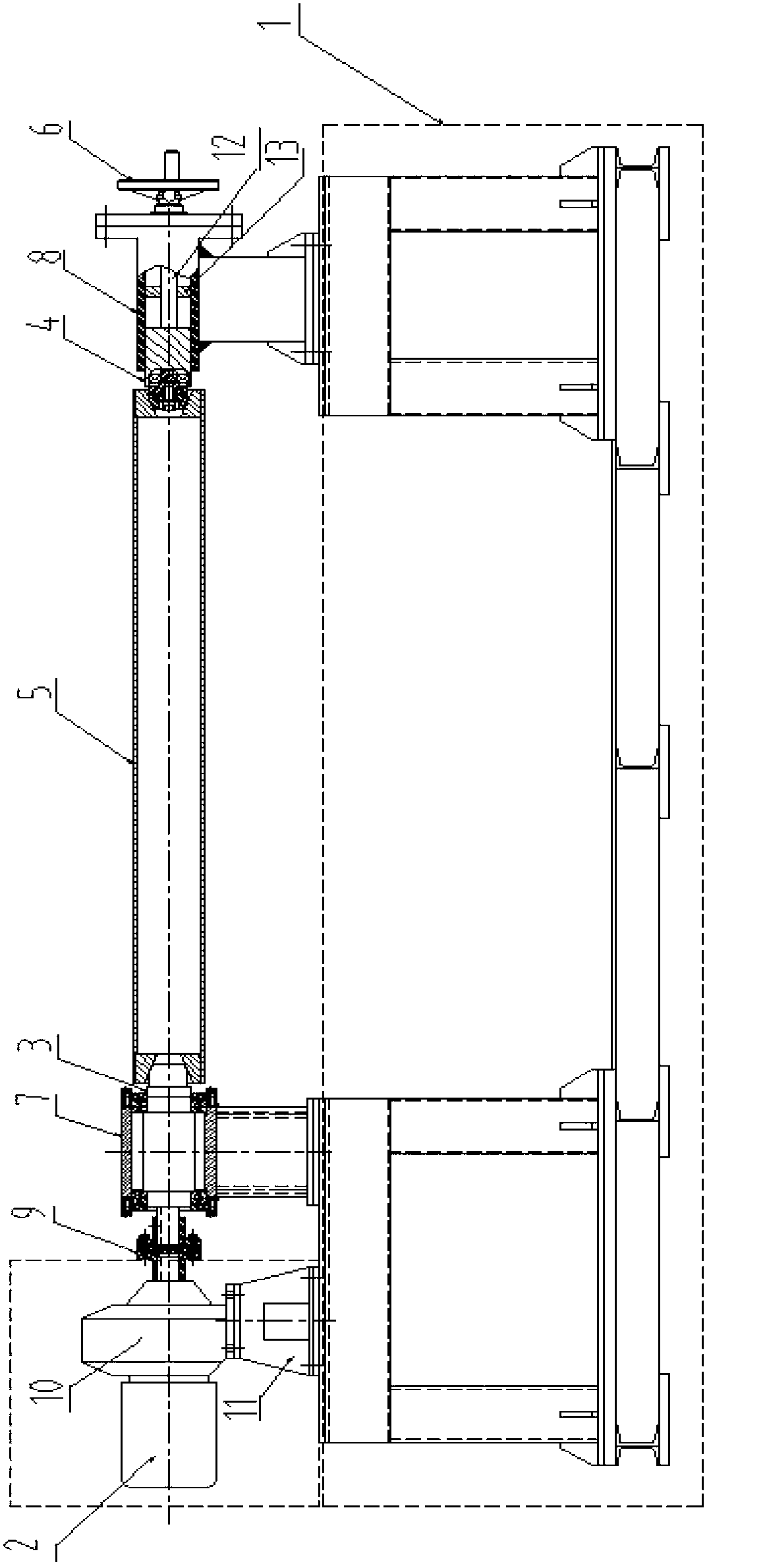

[0012] Such as figure 1 Shown, the present invention comprises frame 1, hand wheel 6, servo drive system and screw nut mechanism, and servo drive system is made up of servo motor 2, reducer 10, reducer support 11, and screw nut mechanism is made up of screw mandrel 12 and Nut 13 forms.

[0013] The frame 1 is made of carbon steel and welded to ensure the overall strength and rigidity of the mechanism. After the frame is welded, it is processed as a whole to ensure the accuracy of the matching mounting surface. The frame 1 is fixed on the ground by anchor bolts.

[0014] The servo drive system is made up of servo motor 2, reducer 10, reducer support 11. It is fixed together with the frame 1 by bolts. The speed reducer 10 is connected with the drive shaft 3 through a coupling 9 to provide power output. Servo motor 2 can realize precise control of copper foil tension.

[0015] The driving shaft 3 is a carbon steel part, and is installed on the driving bearing seat 7 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com