Producing method of environment-friendly composite sizing agent

A production method and an environment-friendly technology, applied in the field of production of environment-friendly combined pulp, can solve the problems of expensive chemical pulp, unfavorable sizing quality stability, increased production cost, etc., achieve short processing time, convenient operation, eliminate pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

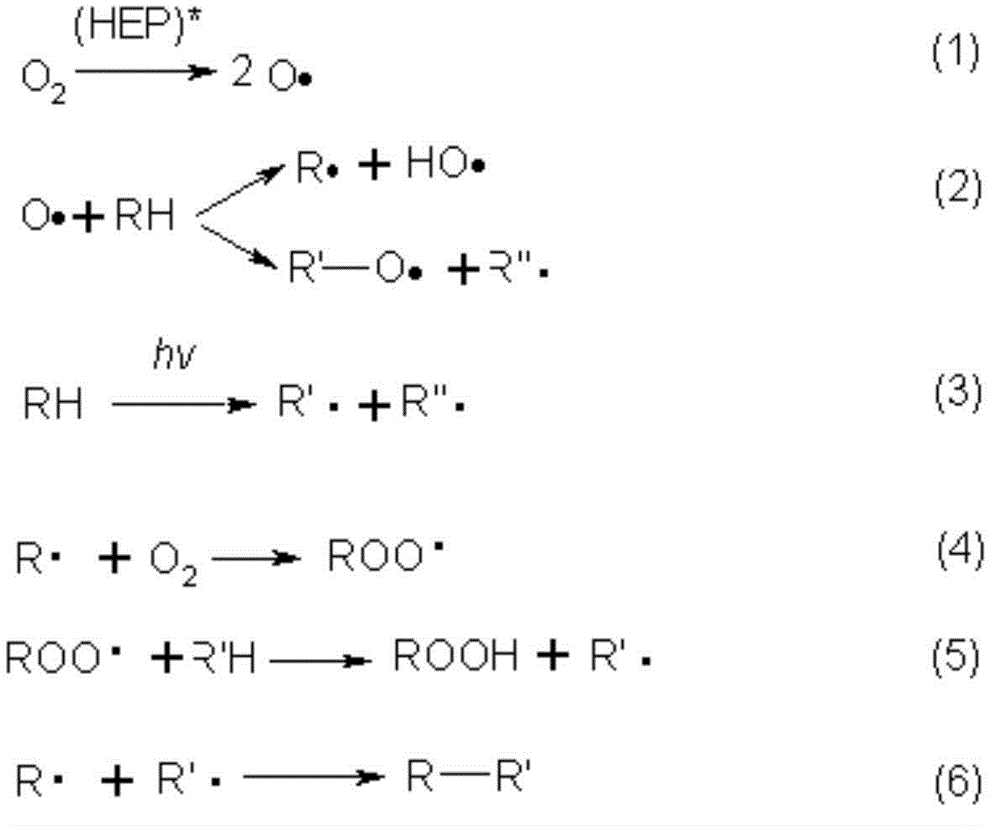

Method used

Image

Examples

Embodiment 1

[0037] Put the potato flour in a drying oven at 80 °C for 24 h, and place the dried starch in an insulated container. The thickness of the starch layer is about 20 mm. Put the container into the processor, and use a vacuum pump to extract the processor so that the pressure in the processor is about 5 Pa. Introduce non-polymerizable gases He and O 2 (the molar ratio is 6:1), until the pressure inside the processor is 25 Pa; turn on the switch to preheat, and apply voltage to the electrodes placed in the processor to modify the starch. Adjust the discharge frequency of the applied voltage to 38.0 MHz, the discharge power to 800 W, the gas flow rate to 750 mL / min, and the processing time to 90 s. Turn off the switch, slowly release the pressure to normal pressure, and take out the starch, which is non-equilibrium plasma modified starch.

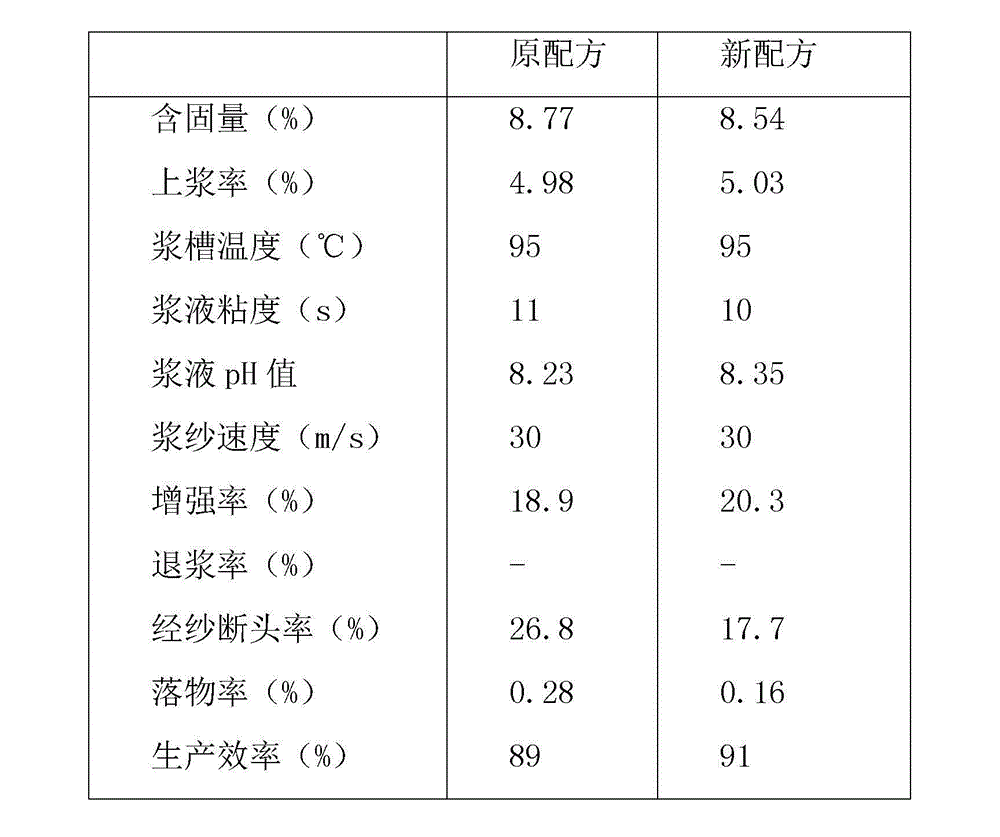

[0038] Configuration of combined size of modified starch. Put 45 parts of the above-mentioned non-equilibrium plasma modified starch (by wei...

Embodiment 2

[0040] Waxy cornmeal was dried in a drying oven at 70 °C for 24 h, and the dried starch was placed in an insulated container with a starch layer thickness of about 20 mm. Put the container into the processor, and use a vacuum pump to extract the processor so that the pressure in the processor is approximately equal to 4 Pa. Introduce non-polymerizable gas He and air (molar ratio is 3:1) until the pressure inside the processor is 30 Pa; turn on the switch to preheat, and apply voltage to the electrodes placed in the processor to modify starch. Adjust the applied voltage discharge frequency to 38.0 MHz, the discharge power to 800 W, the gas flow rate to 900 mL / min, and the processing time to 120 s. Turn off the switch, slowly release the pressure to normal pressure, and take out the starch, which is non-equilibrium plasma modified starch.

[0041] Configuration of combined size of modified starch. Put 32 parts of non-equilibrium plasma-modified starch, 68 parts of acid-thinned...

Embodiment 3

[0043] Put the cassava flour in a drying oven at 80 °C for 24 h, and place the dried starch in a treatment insulated container with a starch layer thickness of about 15 mm. Put the container into the processor, and use a vacuum pump to extract the processor so that the pressure in the processor is approximately equal to 4 Pa. Introduce non-polymerizable gases He and O 2 (the molar ratio is 8:1), until the pressure inside the processor is 30 Pa; turn on the switch to preheat, and apply voltage to the electrodes placed in the processor to modify the starch. Adjust the discharge frequency of the applied voltage to 38.0 MHz, the discharge power to 700 W, the gas flow rate to 600 mL / min, and the processing time to 120 s. Turn off the switch, slowly release the pressure to normal pressure, and take out the starch, which is non-equilibrium plasma modified starch.

[0044] Configuration of combined size of modified starch. Put 50 parts of non-equilibrium plasma modified starch, 50 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com