Shield tunnel construction environment simulation unit

A construction environment and simulation device technology, applied in tunnels, teaching models, instruments, etc., can solve problems such as fixed excavation routes, small model soil box capacity, and narrow application area, and achieve rich stratum environment, eliminate boundary effects, and material capacity big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

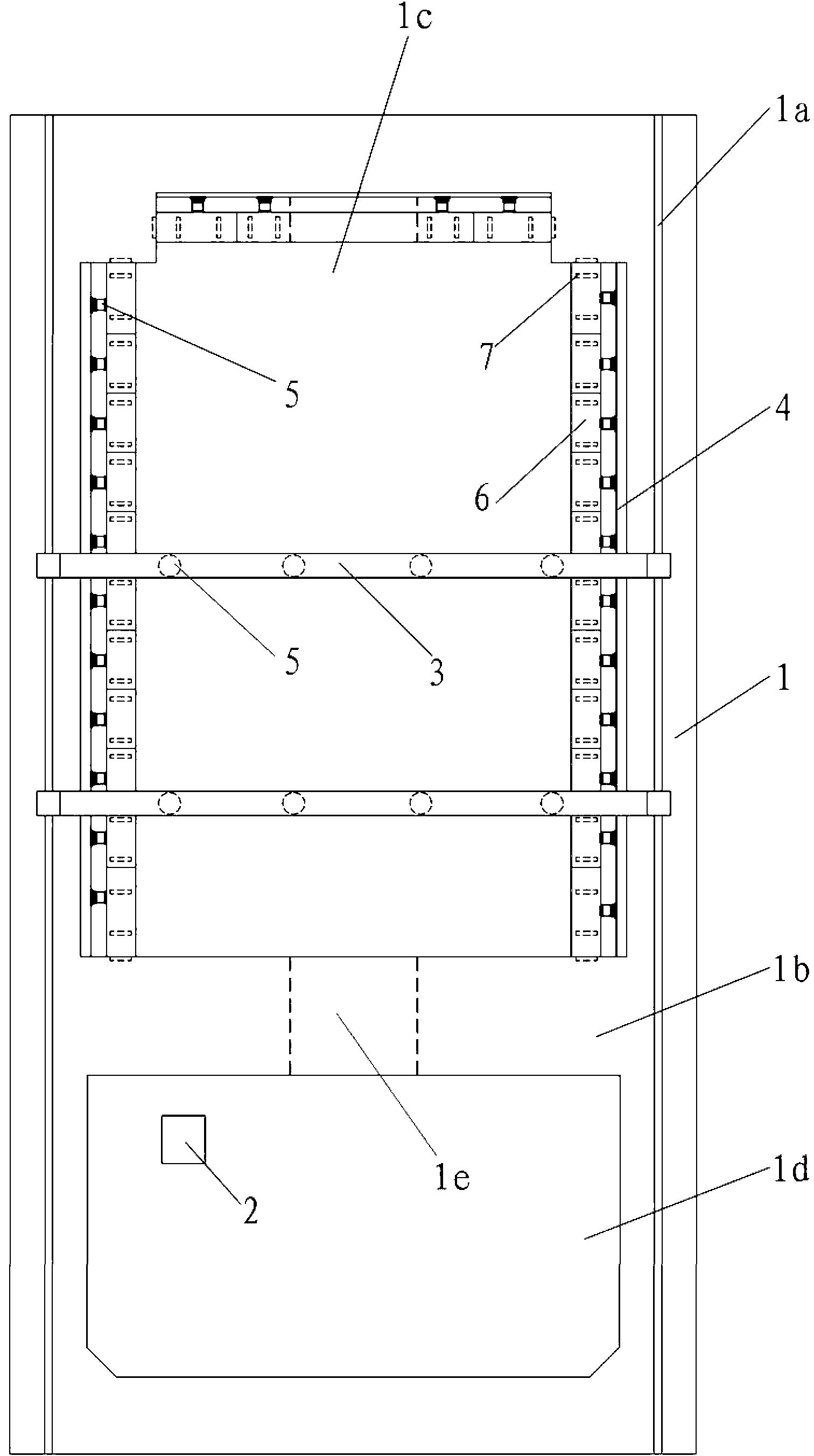

[0024] figure 1 It is shown that a shield tunnel construction environment simulation device includes a foundation groove 1, a hydraulic loading device 2, and a control device. It is characterized in that: the foundation groove 1 is a cuboid-shaped sunken reinforced concrete foundation groove. The tops of the left and right side walls of the tank 1 are provided with channels 1a, the casters of the columns on both sides of the mobile reaction frame 3 are installed in the channel 1a, and the lower surface of the mobile reaction frame 3 is provided with a plurality of jacks 5.

[0025] The foundation trench 1 is divided into an environmental simulation field 1c and a starting well 1d by a partition wall 1b along the longitudinal direction. The partition wall 1b is provided with a shield tunnel entrance 1e, and the left, right and front walls of the environmental simulation field 1c are A fixed anti-force grid 4 is installed, and a plurality of jacks 5 in the horizontal direction a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com