Water stemming

A water blasting mud and aqueous solution technology, applied in blasting, explosives, etc., can solve the problems of insufficient contact with the blasthole wall, failure to achieve sealing effect, easy deformation and water seepage, etc., to achieve excellent plugging of blastholes and promote cooling , smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 The present invention only contains the water gun putty of flame suppressant

[0031] Dissolve a certain amount of potassium chloride and sodium chloride in water, and send them to the RCEG-12 Rotaclip packaging machine produced by Dibotai Company in the United States for canning. The outer packaging film 1 adopts a commercially available PE dry composite film to produce water cannons. The aqueous solution of mud and water cannon mud contains 1.5% potassium chloride and 1.5% sodium chloride.

[0032] When the water blasting mud obtained in this example is used in coal mining, after the explosives and detonators are loaded according to the blasting design instructions, three pieces of water blasting mud are loaded into each blast hole, and the hole is blocked after the water blasting mud, mainly using three-component clay Or clay, according to the diameter and length of the blast hole, until it is completely filled.

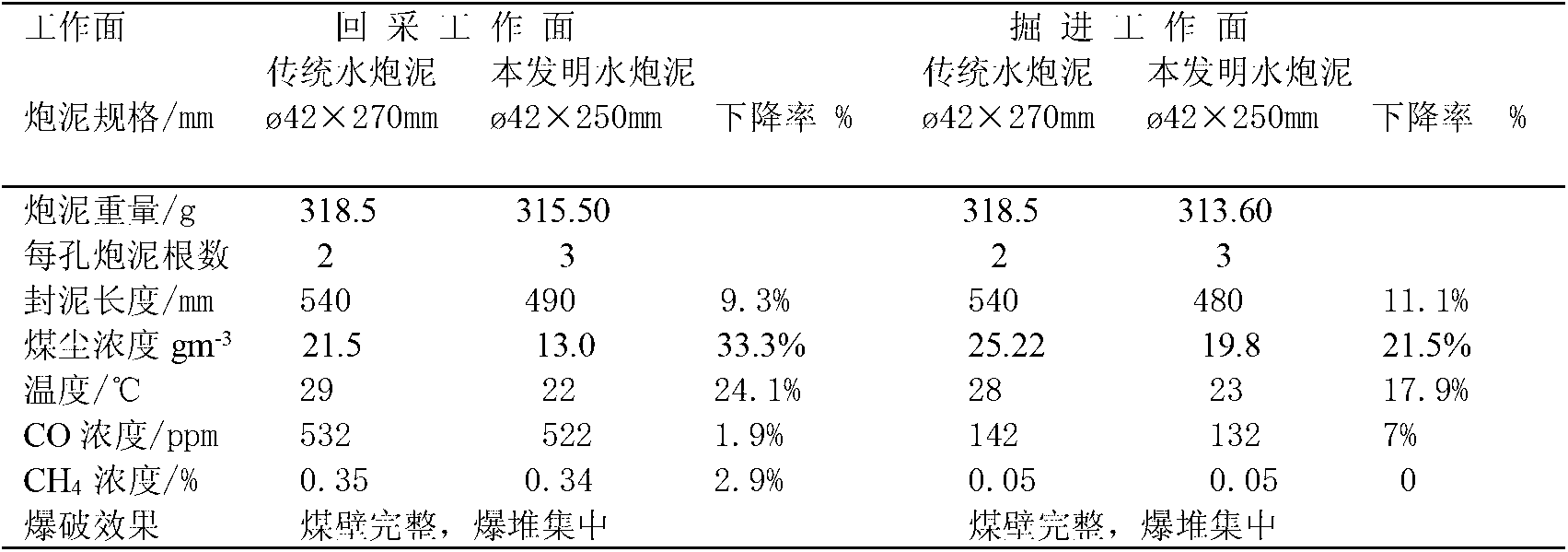

[0033] Table 1 shows the on-site compar...

Embodiment 2

[0036] Embodiment 2 The present invention contains flame suppressant and foaming agent water gun putty

[0037]Dissolve a certain amount of potassium chloride and sodium chloride in water, then add a certain amount of sodium nitrite to mix, and then send it to the RCEG-12 Rotaclip packaging machine produced by Dibotel Corporation of the United States for canning. The PE dry-type composite membrane sold is produced to obtain water taphole mud, and the aqueous solution of water taphole mud contains 2% potassium chloride, 2% sodium chloride, and 0.37% sodium nitrite.

[0038] When the water blasting mud obtained in this example is used in coal mining, after the explosives and detonators are loaded according to the blasting design instructions, three pieces of water blasting mud are loaded into each blast hole, and the hole is blocked after the water blasting mud, mainly using three-component clay Or clay, according to the diameter and length of the blast hole, until it is complet...

Embodiment 3

[0043] Embodiment 3 The present invention contains flame suppressant, foaming agent and sodium bicarbonate water gun putty

[0044] Dissolve a certain amount of potassium chloride and sodium chloride in water, then add a certain amount of sodium nitrite and sodium bicarbonate to mix, and then send it to the RCEG-12 Rotaclip packaging machine produced by Dibotai Company in the United States for canning. The packaging film 1 adopts commercially available PE dry-type composite film to produce water taphole mud. The aqueous solution of water taphole mud contains 2% potassium chloride, 2% sodium chloride, 0.37% sodium nitrite, and 2% sodium bicarbonate.

[0045] When the water blasting mud obtained in this example is used in coal mining, after the explosives and detonators are loaded according to the blasting design instructions, two pieces of water blasting mud are loaded in each blast hole, and the hole is blocked after the water blasting mud, mainly using three-component clay Or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com