A method for detecting malt dissolution degree in barley malting process

A barley and malt technology, applied in the field of beer production, can solve the problems of inability to judge the change of substances, the dissolution of barley, and the cumbersome and complicated detection methods, and achieve the effect of being conducive to industrial promotion and application and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Determination of green malt starch viscosity in the germination step in the barley malting process

[0031] ①Wheat soaking and germination: After the barley sample is sieved, it is washed with tap water to remove floating wheat and impurities. Treated barley with 0.1% Ca(OH) 2 Soak for 30min, the liquid surface soaks the barley surface, soak the wheat for 4h and cut off the water for 8h as a soaking cycle, soak the wheat for 48h, and spray 0.3mg / L of gibberellin. During the whole maceration process, the maceration temperature was 14°C.

[0032] After the last immersion, the barley is germinated at a temperature of 18°C and a relative humidity of 90%. During the germination period, the barley is turned every 8 hours. After the germination is completed, green malt can be obtained.

[0033] The barley may be selected from Australian barley and domestic barley.

[0034] The wheat soaking and germination in step 1 are all carried out in a constant temperature ...

Embodiment 2

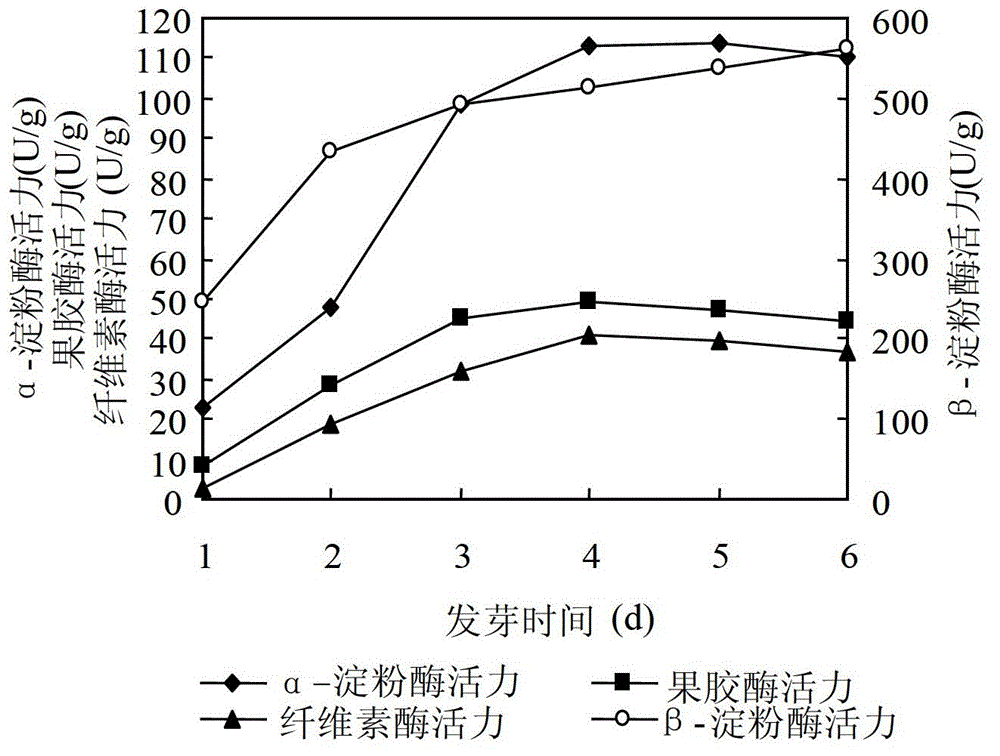

[0044] Example 2 Barley Germination Time and Malt Dissolution

[0045] According to the method described in Example 1, the Australian barley was soaked and germinated according to step 1, and green malt was taken every 24h of germination. The green malt was placed in an oven, dried at 50° C. for 24 hours, and then the malt roots were removed to obtain malt, and the enzyme activity in the malt was determined by the following method.

[0046] For the preparation of maltase solution and the determination of α and β amylase, see [Guan Bin, Li Shan, Xun Juan, etc.. Research on the dynamic changes of amylase activity during malting barley. China Brewing, 2009, (5): 69~ 72], for the method for the determination of pectinase activity, see [Wang Tianlong, Qiu Hongwei, Chen Haihua, etc., Research on the conditions for the determination of pectinase activity by 3,5-dinitrosalicylic acid method. Food and Machinery, 2008, 24 (3 ): 96~99], for cellulase determination methods, see [Liu Guos...

Embodiment 3

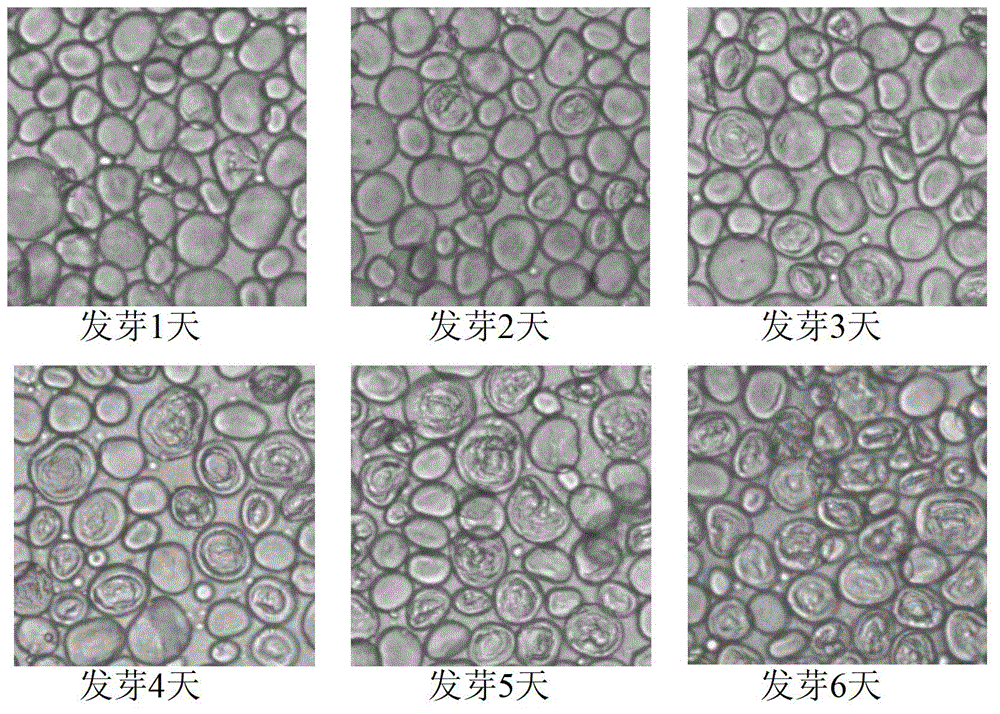

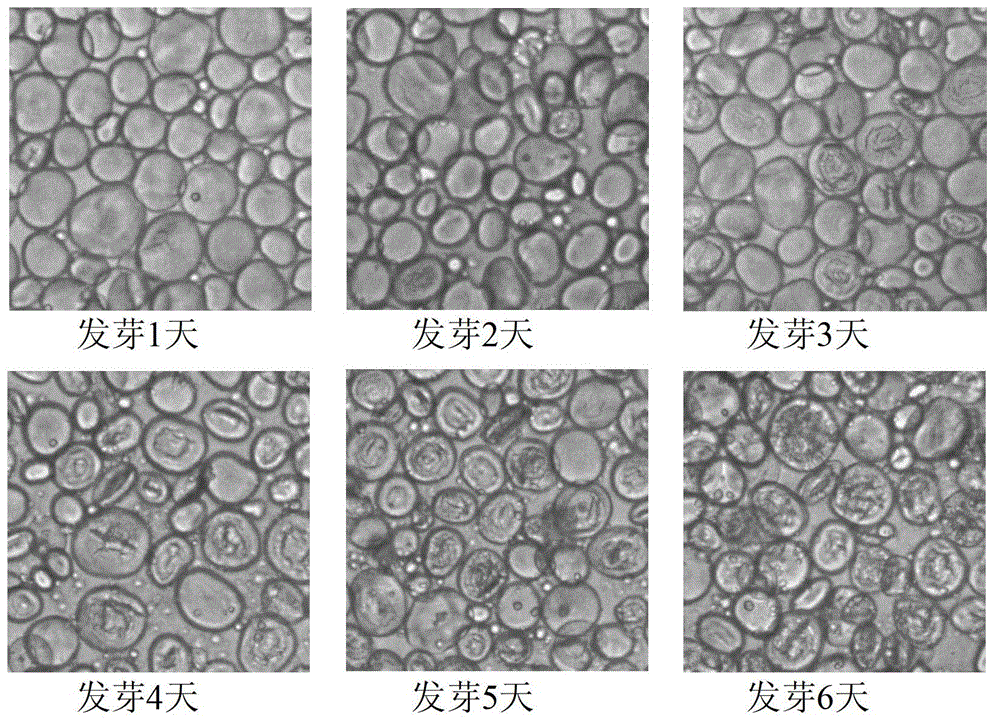

[0048] Example 3 Correlation between green malt starch viscosity and starch granule breakage rate during barley germination

[0049] According to the method described in Example 1, Australian barley or domestic barley is soaked and germinated, and green malt is obtained every 24h of germination, and green malt starch is obtained according to step 2 in Example 1, and green malt starch is measured according to the method in step 3. . In addition, an appropriate amount of the green malt starch obtained in step ② was taken and photographed under a 40×10 times digital microscope to obtain a characteristic image of green malt starch granules during barley germination, and the damage rate of starch granules was calculated.

[0050] The acquisition method of the starch granule characterization image and the calculation method of the starch granule breakage rate are as follows:

[0051] Take a small amount of green malt starch in a plate, add an appropriate amount of 0.2% Tween-80 sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com