Method for quantitatively analyzing inclusions in steel under laser microscope

A technology of laser microscope and quantitative analysis, which is applied in the direction of material analysis, material analysis, and measurement device by optical means, which can solve the problems of error, large amount of data, and large workload of manual statistics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

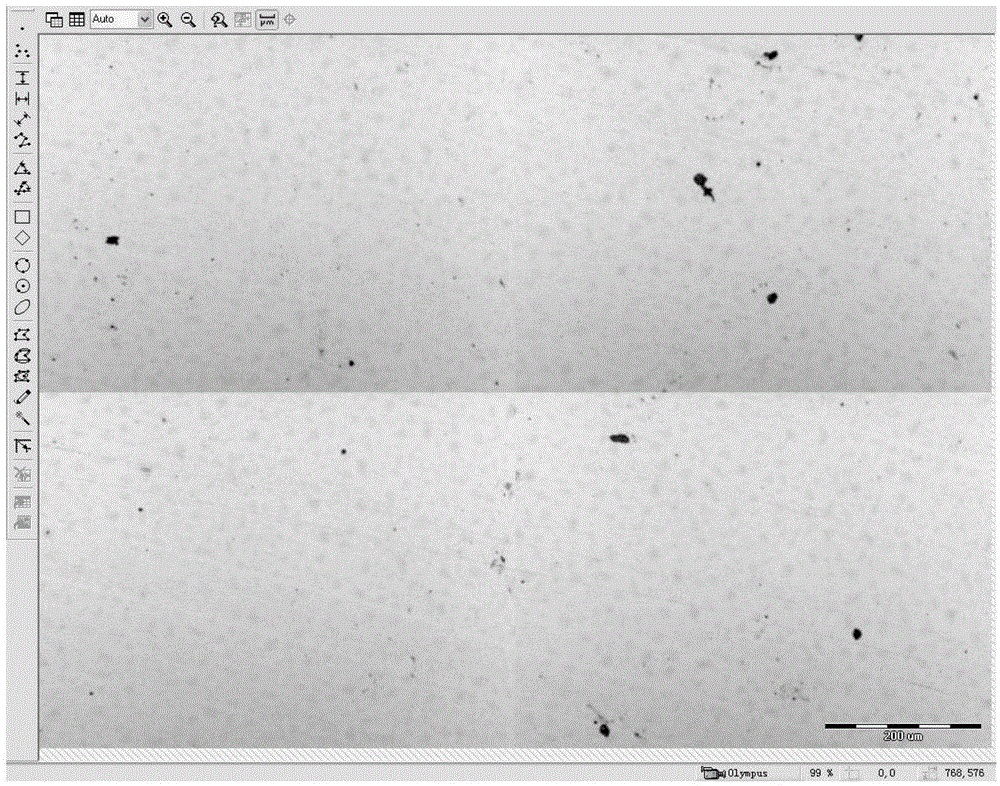

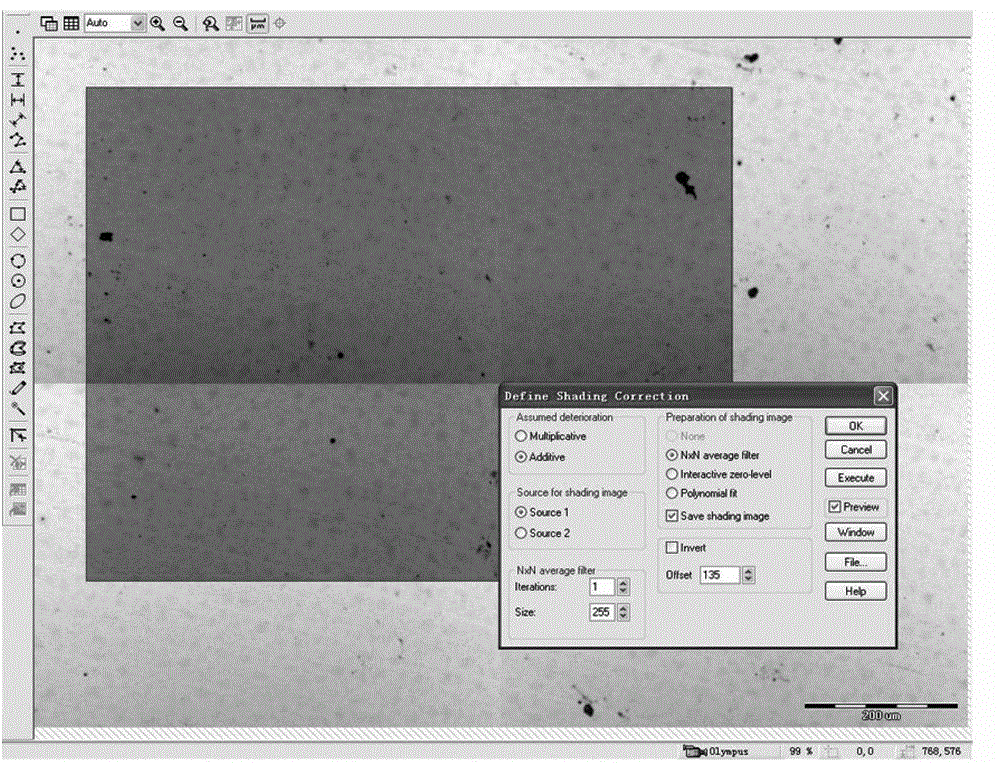

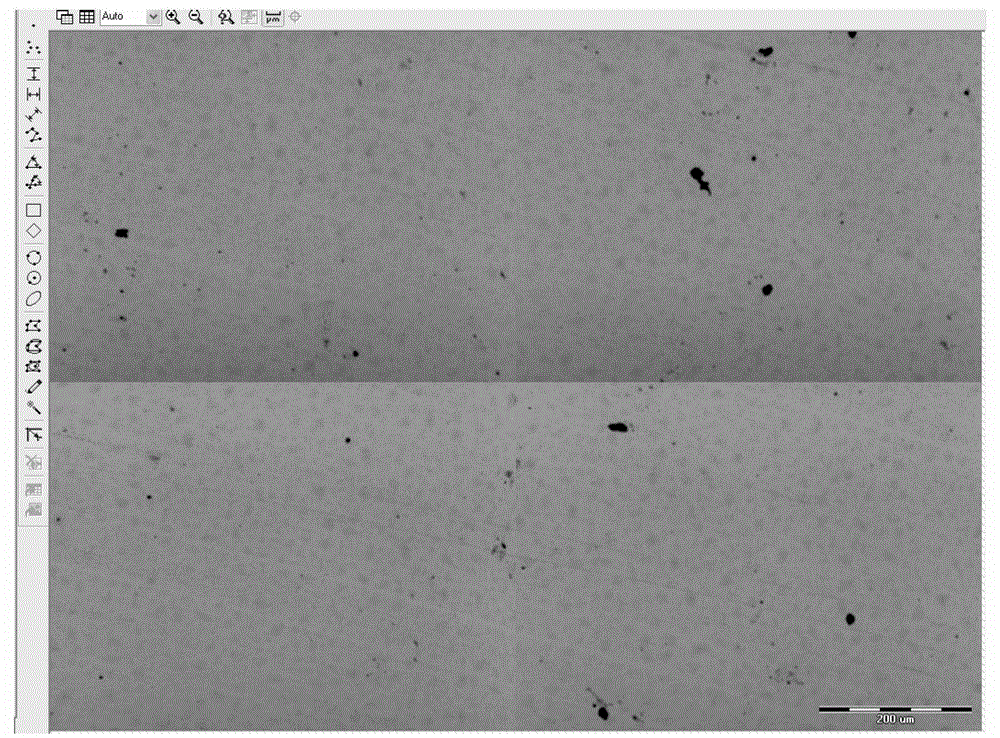

Image

Examples

Embodiment Construction

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0022] A method for quantitatively analyzing inclusions in steel under a laser microscope, taking the analysis of inclusions in a high-carbon steel wire rod with a diameter of 15mm as an example, the method includes the following steps:

[0023] 1. Sampling: According to the shape and type of the sample to be tested, the sample is intercepted with reference to the national standard, so that the surface area of the sample meets the requirements of the national standard. The microscope has no special requirements for the scanning surface and shape. The rolling direction is cut longitudinally, and the section passes through the diameter direction.

[0024] 2. Mounting: Put the sample to be tested face down into the mounting machine, add resin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com