Volume resistivity test method of ethylene vinyl acetate copolymer (EVA) adhesive film used for photovoltaic module packaging

A photovoltaic module packaging and volume resistivity technology, applied in the field of measurement, can solve the problems of large measurement errors, troublesome operation, and low measurement accuracy, and achieve the effects of accurate volume resistivity, good adhesion, and simple calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] One, the volume resistivity testing method of EVA adhesive film for photovoltaic module encapsulation of the present invention, carry out according to the following steps:

[0038] 1. Make samples:

[0039]1-1. Use the EVA film G102-1 produced by Guangzhou Lushan New Materials Co., Ltd. with a thickness of 0.5mm, and cut the EVA film into 5 samples of 5cm×5cm in size with a utility knife. A 5×5cm auxiliary electrode (25cm 2 ).

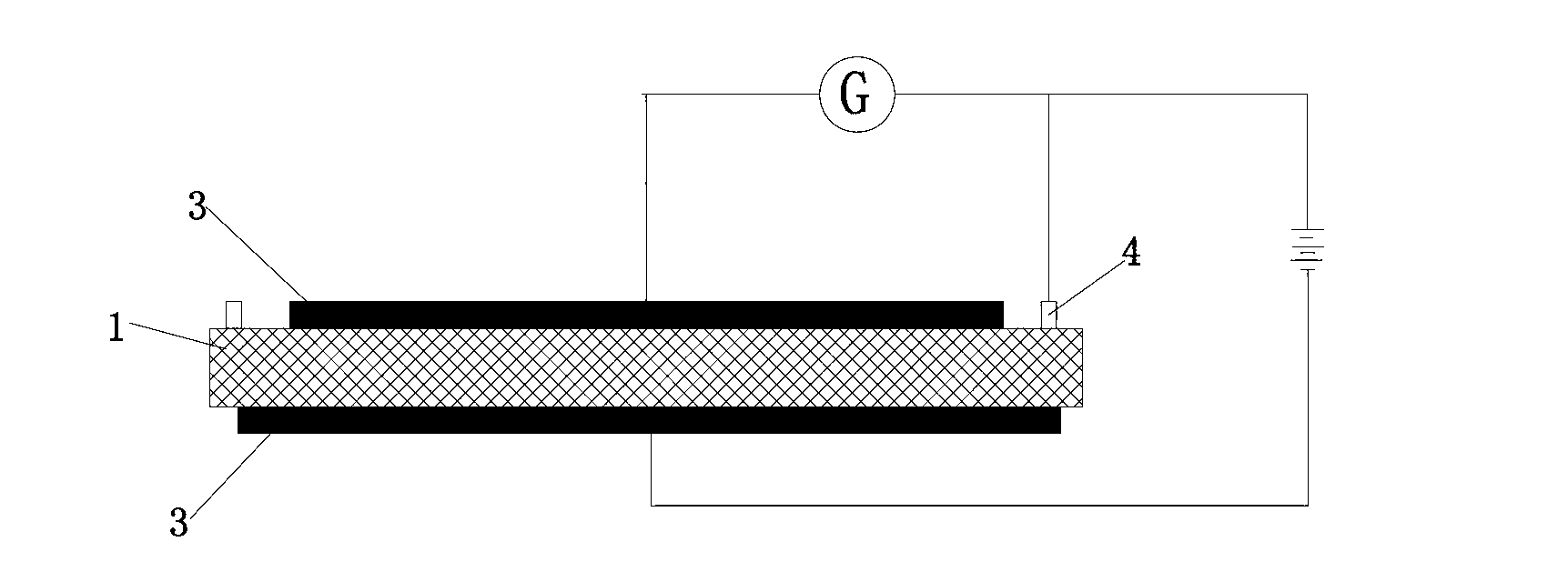

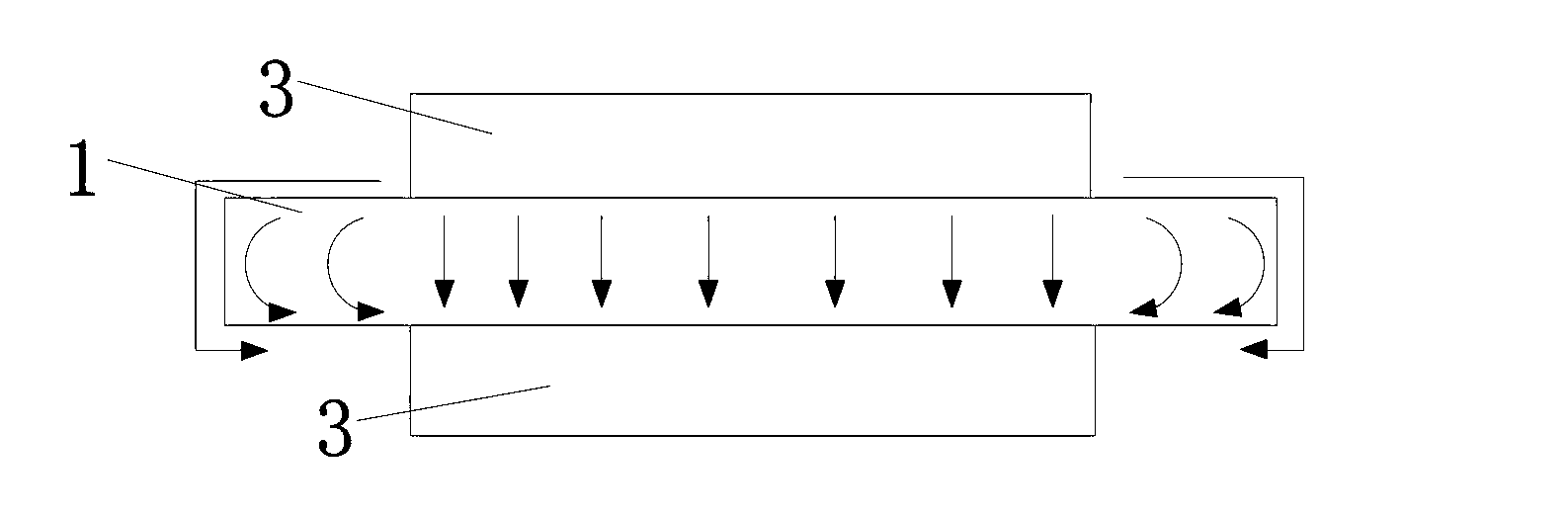

[0040] 1-2. Stack the auxiliary electrode 2, EVA film 1, and auxiliary electrode 2 in order from top to bottom, put them into the laminator, and place a mold frame to control the thickness around them. Laminate at a temperature of 140°C , evacuate for 6 minutes, pressurize for 1 minute, and hold the pressure for 15 minutes to carry out lamination, cooling, and trimming to prepare test samples (such as Figure 4 As mentioned), the sample thickness is required to be uniform and free of air bubbles. Store the samples in a container with a desic...

Embodiment 2

[0051] The EVA film G103-1 produced by Guangzhou Lushan New Material Co., Ltd. is used, with a thickness of 0.5mm. According to the same sample preparation method and process as in Example 1, the volume resistivity using the auxiliary electrode, the relative volume resistivity and the wet insulation resistance using the auxiliary electrode were tested respectively, and the results are shown in Table 1.

[0052] The above-mentioned EVA film is adopted, with a thickness of 0.5mm. According to the same sample preparation method and process as in Example 1, the volume resistivity measured by the conventional method was tested, and the results are shown in Table 1.

Embodiment 3

[0054] The EVA film G104-1 produced by Guangzhou Lushan New Material Co., Ltd. is used, with a thickness of 0.5mm. According to the same sample preparation method and process as in Example 1, the volume resistivity using the auxiliary electrode, the relative volume resistivity and the wet insulation resistance using the auxiliary electrode were tested respectively, and the results are shown in Table 1.

[0055] The above-mentioned EVA film is adopted, with a thickness of 0.5mm. According to the same sample preparation method and process as in Example 1, the volume resistivity measured by the conventional method was tested, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com