Approximate three-dimensional setting method of proportion integration differentiation (PID) temperature control parameters of laser device based on narrow field theory

A laser and parameter technology, used in lasers, laser parts, semiconductor lasers, etc., can solve the problems of small calculation amount, large system overhead, low control accuracy, etc., and achieve stable dynamic response, low system overhead, and fast response speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the present invention is described in further detail:

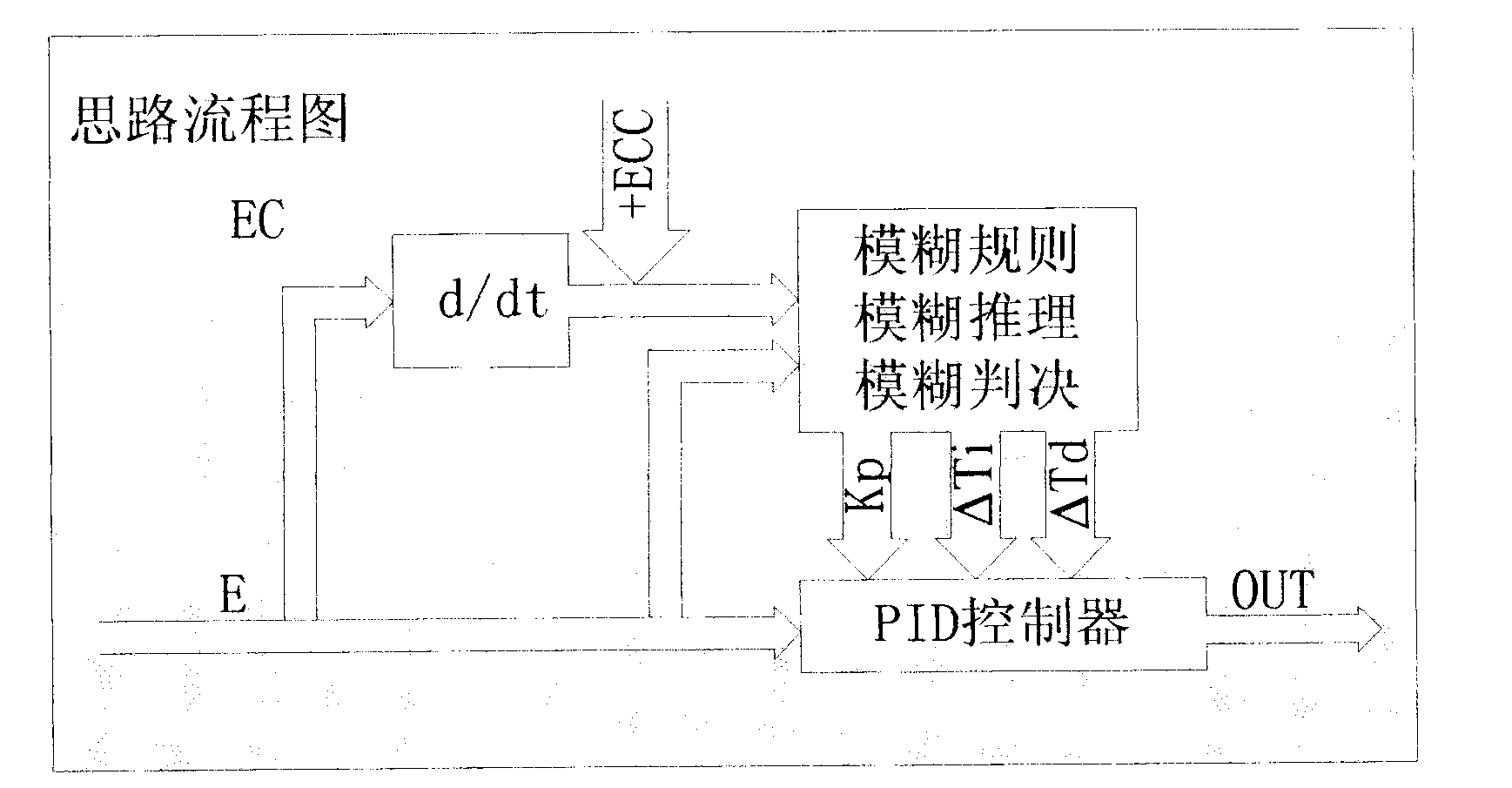

[0023] Such as figure 1 Shown: Approximate three-dimensional tuning method of laser PID temperature control parameters based on narrow domain theory, the method is: introduce the third dimension variable ECC, establish fuzzy rules; measure the fitting data, perform fuzzy reasoning; optimize fuzzy rules for fuzzy judgment, and realize fuzzy control.

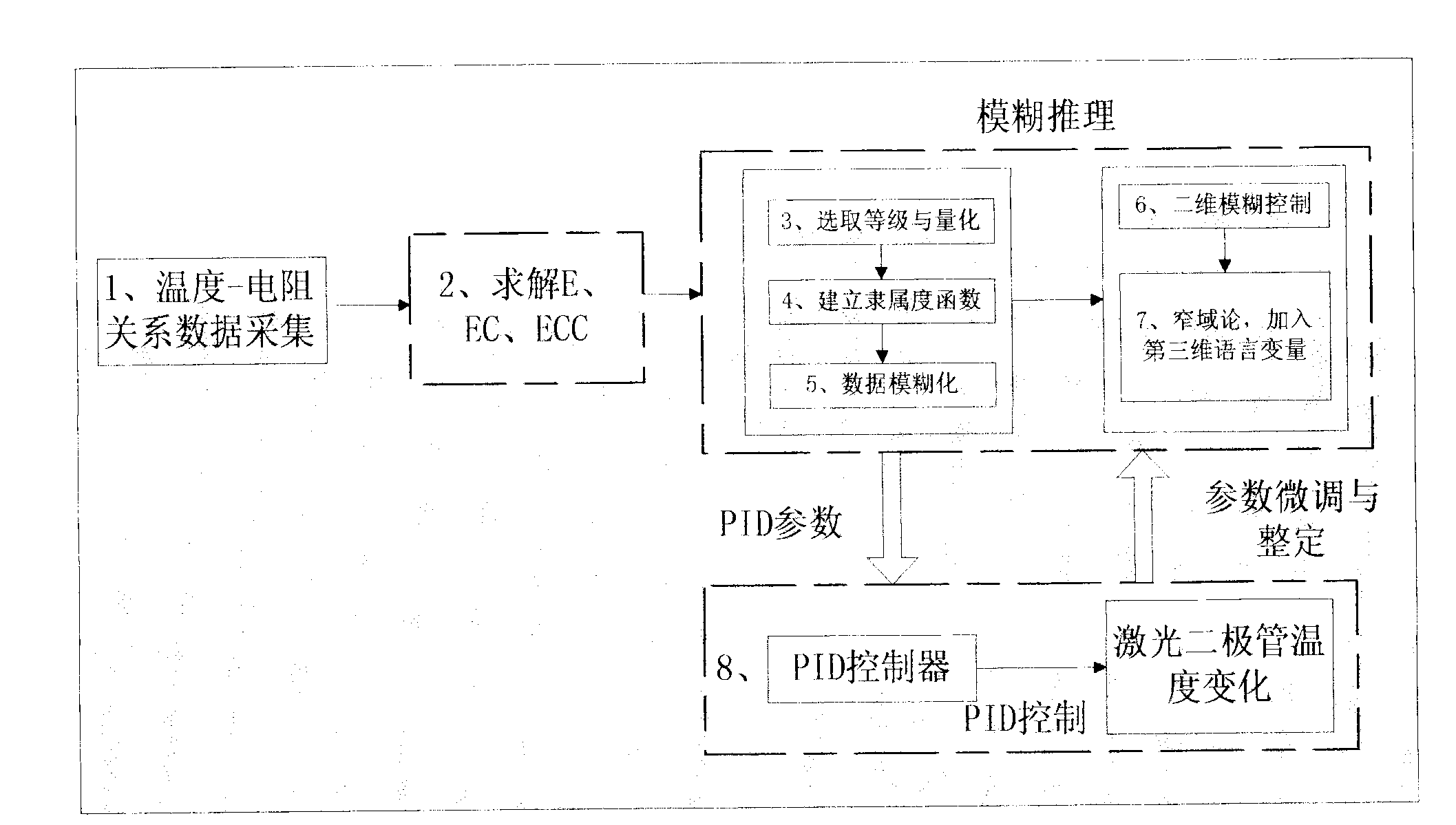

[0024] Such as figure 2 As shown, the approximate three-dimensional tuning method of laser PID temperature control parameters based on the narrow field theory of the present invention includes the following specific implementation steps:

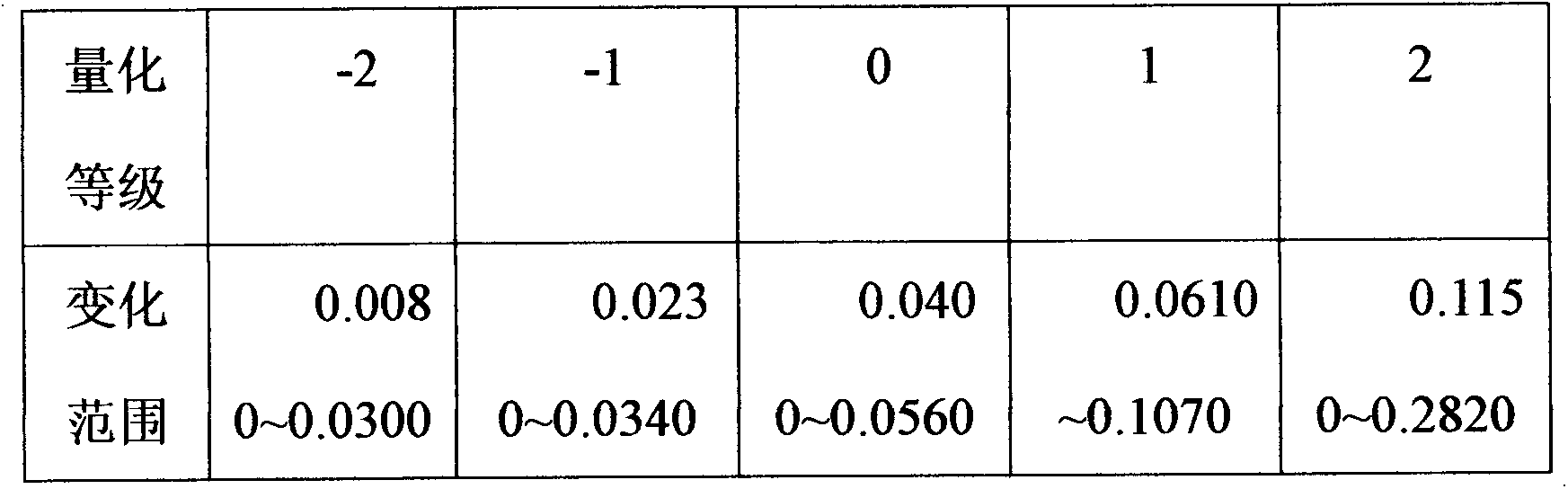

[0025] 1. Temperature-resistance relationship data acquisition: NTC thermistor with high sensitivity, small size and negative temperature coefficient is used, and the temperature measurement circuit is used to convert the change of resistance into the change of voltage. By recording...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com