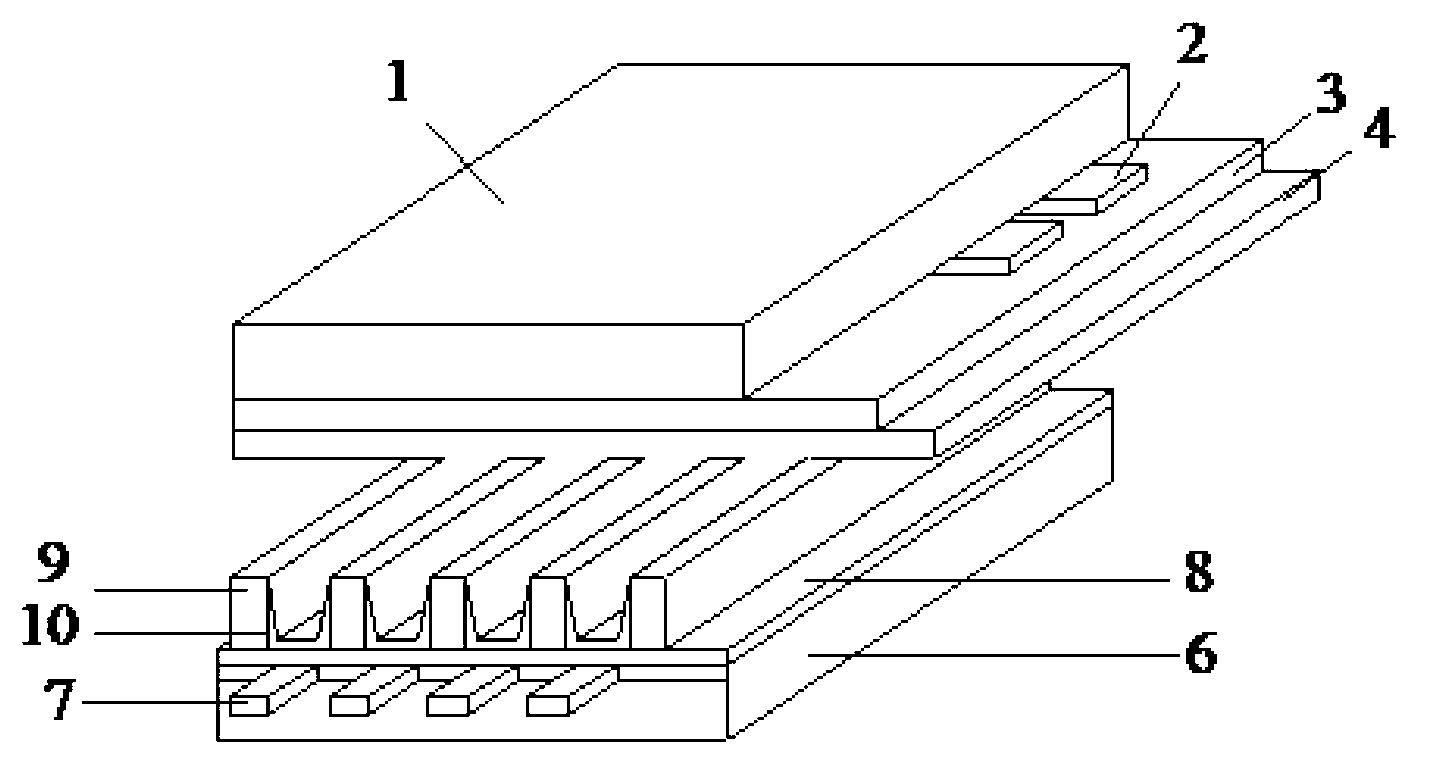

Protective layer structure of plasma display panel (PDP) front glass plate and preparation method thereof

A technology of front glass plate and protective layer, which is applied in the field of protective layer structure of Plasma Display (PDP), can solve the problems of image quality degradation, opaque film, and lack of protective effect, so as to reduce ignition voltage and addressing time, the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

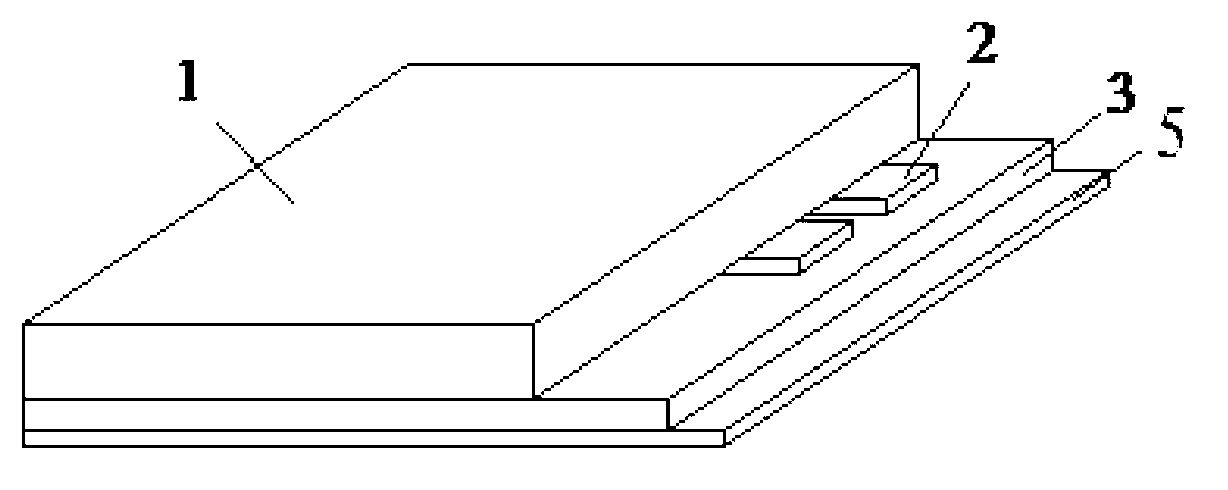

[0022] Such as figure 2 As shown, a protective layer structure of the PDP front glass plate is located on the surface of the transparent medium 3 of the PDP front glass plate, and there is a scanning and sustaining transparent electrode 2 between the transparent medium 3 and the glass substrate 1 . The protective layer structure 5 is a small amount of LaB doped 6 MgO material, where LaB 6 The incorporation amount of the PDP is limited not to significantly reduce the light transmittance of the PDP front glass plate (the decrease rate of the light transmittance of the PDP front glass plate is limited to no more than 5%~10%).

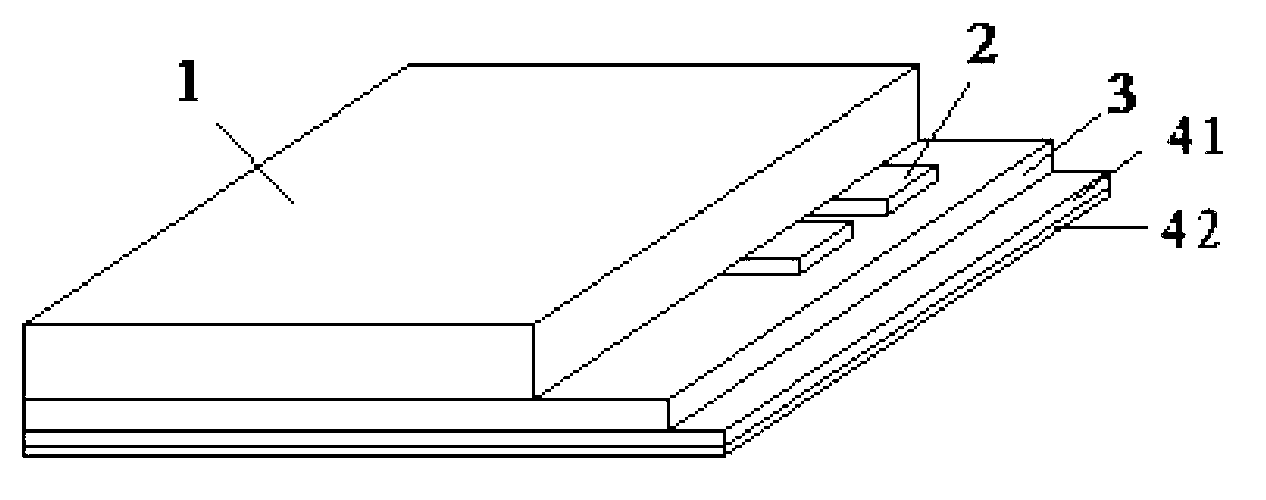

[0023] Such as image 3 As shown, a protective layer structure of the PDP front glass plate is located on the surface of the transparent medium 3 of the PDP front glass plate, and there is a scanning and sustaining transparent electrode 2 between the transparent medium 3 and the glass substrate 1 . The protective layer structure includes a MgO protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com