Nonaqueous electrolyte solution, method for producing same, and nonaqueous electrolyte battery using the electrolyte solution

A non-aqueous electrolyte and non-aqueous solvent technology, applied in non-aqueous electrolyte batteries, non-aqueous electrolytes, electrolytes, etc., can solve the problems of reduced charge and discharge efficiency in the first cycle, increased irreversible capacity, and increased resistance, and achieves good results. Good film formation effect, good high temperature storage characteristics, and good initial characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0399] The present invention is explained in more detail by the synthesis examples, experimental examples, comparative experimental examples, comparative examples and examples given below, but the present invention is not limited to these examples.

Synthetic example

[0400] Synthesis example (methylene bissulfonate derivatives of the present invention and comparative compounds)

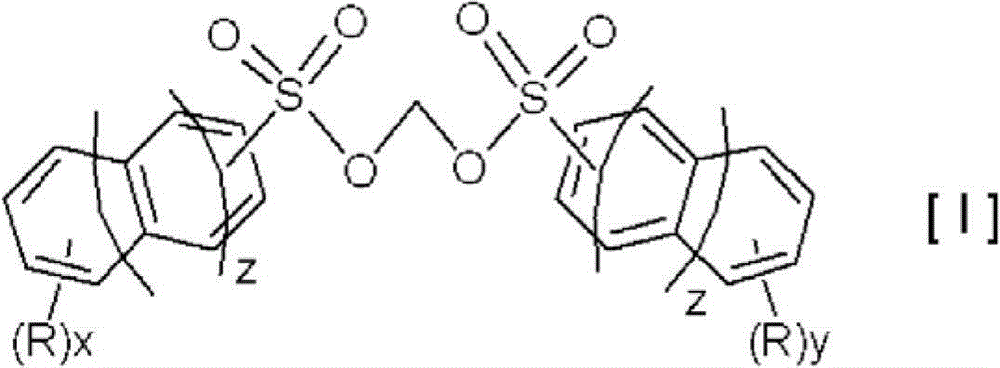

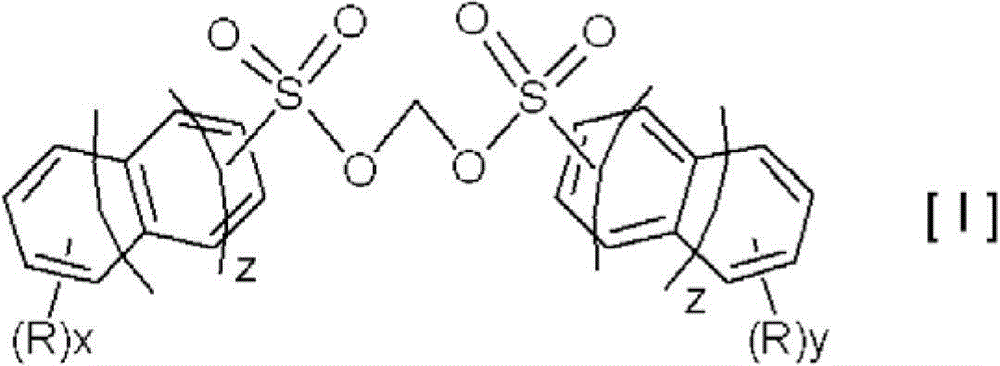

[0401] [Methylene bissulfonate of the present invention]

Synthetic example 1

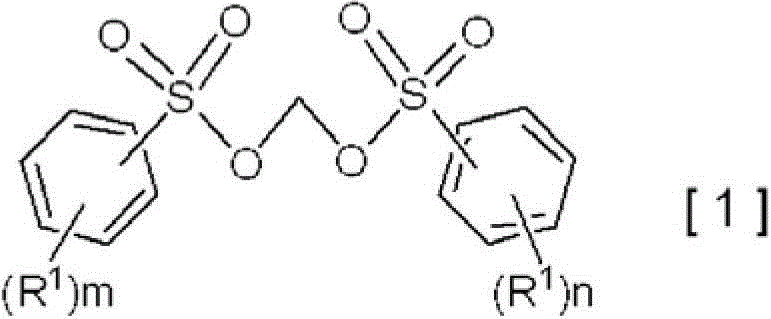

[0402] Synthesis Example 1. Synthesis of Compound No.1 [Methylenebis(benzenesulfonate)]

[0403]

[0404] In dimethyl carbonate (10 mL), methylene bis(chlorosulfonate) [ClSO 2 OCH 2 OSO 2 Cl] (1.5g, 6.1mmol) and pyridinium benzenesulfonate (2.8g, 12.0mmol) were stirred at 55°C for 3 hours. After the reaction, the precipitated pyridinium chlorosulfonate salt was filtered off and concentrated under reduced pressure to obtain a light brown solid. After adsorption treatment with activated carbon, it was purified by recrystallization to obtain the target methylene bis(benzenesulfonate) (1.2 g, 3.5 mmol) in a yield of 58%. 1 The measurement results of H NMR are shown below.

[0405] 1 H NMR (CD 3 CN); δ=7.75-7.70(m,6H),7.58-7.53(m,4H),5.82(s,2H)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com