Gas directly-heated type circular drying machine for walnut

A direct-heating, walnut technology, applied in the fields of application, food processing, food science, etc., can solve the problems of walnut kernel rot and deterioration, product quality impact, labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

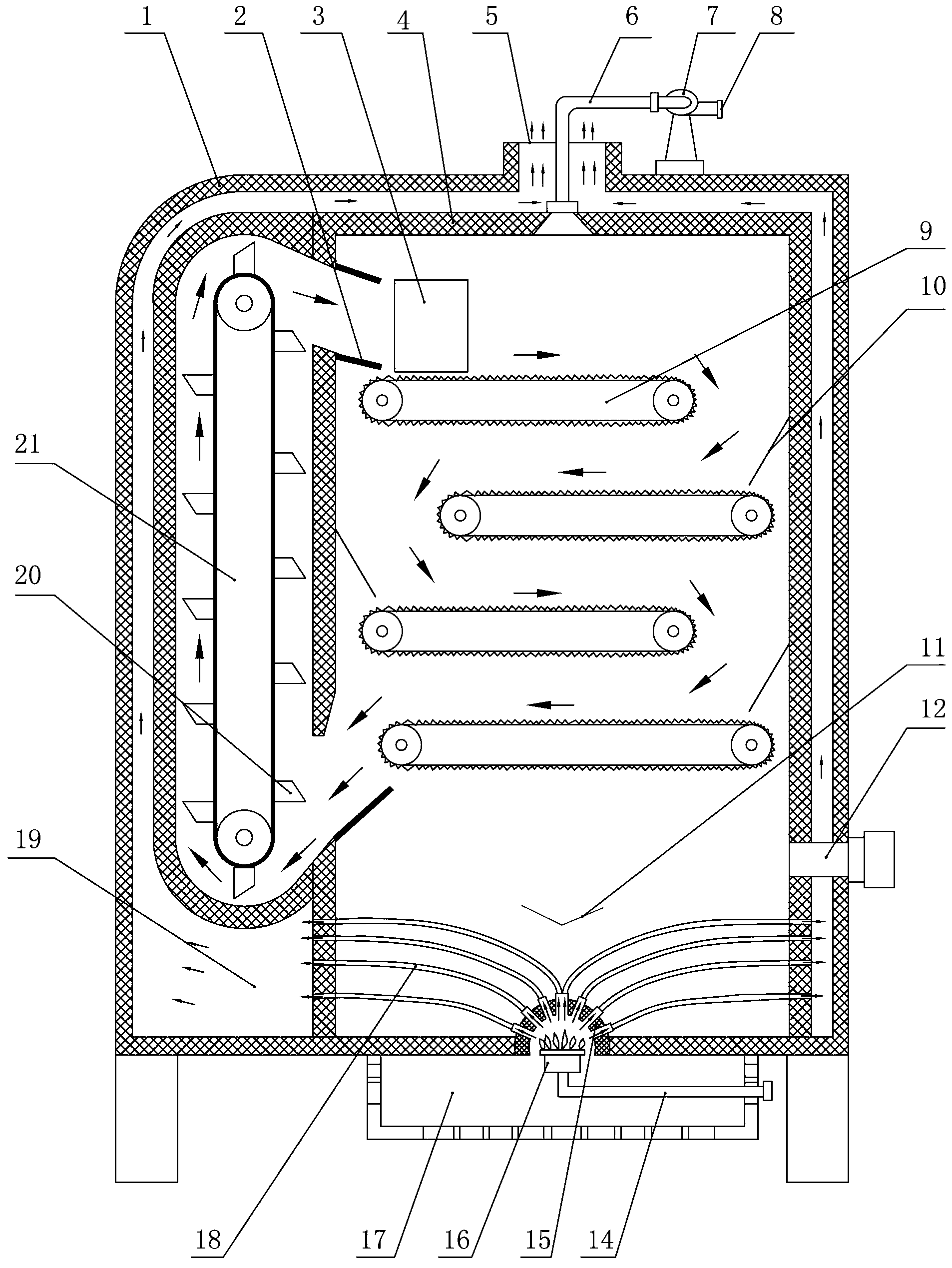

[0009] A gas direct heating type walnut circulation dryer, such as figure 1 As shown, it includes an outer box body 1, an inner box body 4 is arranged at intervals in the outer box body 1, and the lower end of the inner box body 4 peripheral walls is connected with the bottom surface of the outer box body. An exhaust chamber 19 is formed between the inner and outer casings; a spherical combustion chamber 15 is arranged on the bottom surface of the outer casing, a combustion chamber 17 is installed under the bottom surface of the outer casing, a combustion furnace 16 is arranged in the spherical combustion chamber 15, and a combustion furnace 16 It is connected with the air pipe 14. On the side wall of the lower part of the inner box body 4, several radiating pipes 18 communicating with the spherical combustion chamber are arranged, and in the inner box above the radiating pipes 18, a baffle plate 11 arranged in a V shape is arranged; Hot gas enters the exhaust chamber 19 to h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com